Don’t Neglect Your Boat’s Driveline

When was the last time you sent your propeller shaft to the machine shop to be checked? How old are your engine mounts? Have you replaced your cutlass bearing recently?

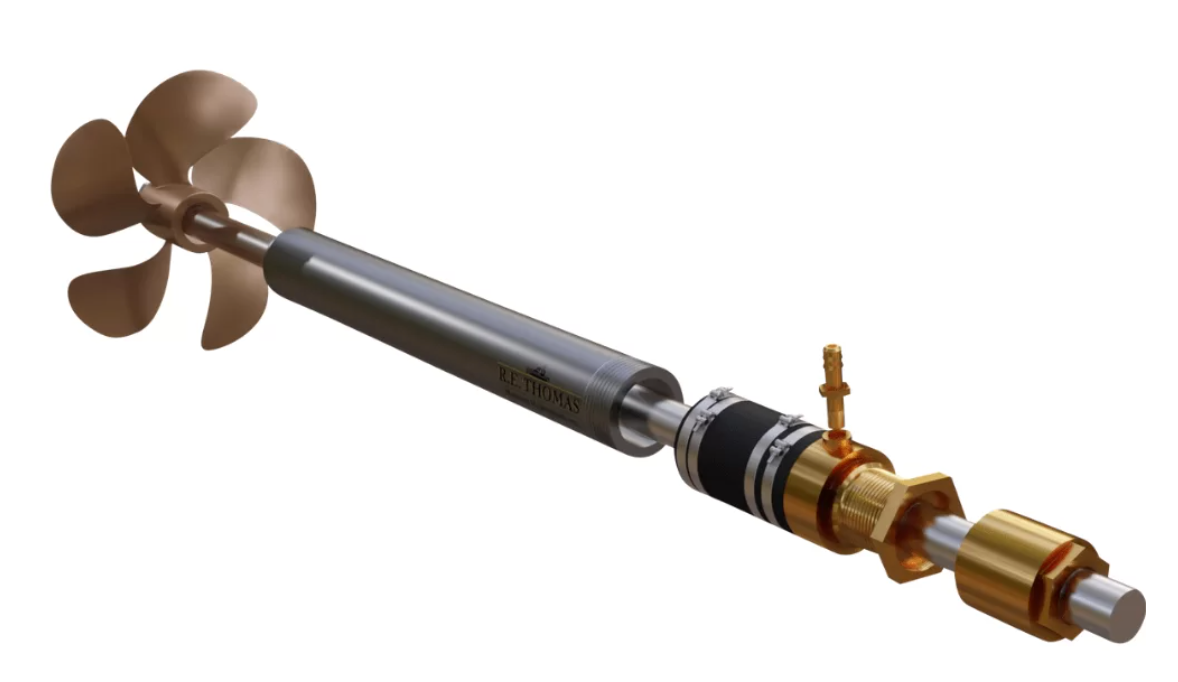

We don’t mean to nag, but we’re trying to make an important point. Powerboats and sailboats with inboard engines generally have rubber in the engine mounts, packing material in the stuffing box and a cutlass bearing in the propeller strut. Of course, there is always a shaft to which the propeller is attached.

It’s Not Just Hours

On recreational boats that get weekend and occasional vacation trip use, total hours of operation are often low and inboard driveline elements are sufficiently simple and robust that they can last for years without failure — but there is always wear.

You don't need a broken drive shaft to spoil your day. Constant vibration, heat and noise may be dampening your fun every time the boat runs. It comes down to accurate alignment in the drivetrain. When things are all on spec, the boat will be at its smoothest and quietest. Plus, it will burn less fuel and have a longer life expectancy.

Professional Diagnosis

Start the process by having your mechanic send out the shaft to verify that it is straight and has no visible wear spots. A good shaft can be trued up, but one that has been run bent or out of alignment for several seasons can be ready to snap from fatigue.

Even a very small amount of damage can start a chain reaction of problems. Also, the shaft itself is a large and heavy piece that must be checked when it is outside the boat. Removing the shaft requires the coupler between the transmission and the stuffing box be disconnected. Additionally, the rudder and stock often need to be removed to slide out the shaft. It slides out of the stuffing box and through the cutlass bearing in the strut before it's free.

This is not a simple DYI project because separating the coupler and sliding it out often requires special tools. An amateur with a pry bar can do real damage.

Start the driveline inspection process with the shaft because even a minor issue with this part can cause noise and vibration problems. If you try to fix those by adjusting engine mounts, you will spend a fair bit of money without fixing your vibration problem. While you are pulling the shaft, send out your props to be checked for accuracy and balance. You don't need to hit the shoal to hurt a prop and start noise and vibration there.

How often should you do this? When you notice a problem of course, but the subtle progress of wear means that every few years, it's worth the modest investment in checking.