Trim Tab Basics: From Installation to Use

“Trim the dish!” was an order bellowed by the coxswain of a ship’s tender in the age of sail, a command indicating bodies needed shifting in order to restore the craft to proper trim. Fortunately, today’s captain isn’t limited to delicately asking big-boned Aunt June to reposition her considerable bulk in efforts to provide a smoother ride. Trim tabs provide an easy, touch of a button solution for making those on the fly adjustments. Here’s the low down on trim tabs — what they are, how they work and how to select the right type for a given application.

Trim 101

A properly trimmed boat is not only safer to operate, it also provides a more comfortable ride, as well as better speed and increased fuel economy. While trim tabs let a captain adjust a boat’s trim when moving, it’s best to achieve static (non-moving) trim to the extent possible before getting underway. This can be as simple as balancing a boat by distributing weight (passengers, coolers, portable fuel tanks, etc.) to keep the hull floating level.

Achieving stationary trim is one thing, however we’ll need to make adjustments once underway to account for speed, water conditions and direction of travel (with regards to waves and wind). Smaller boats, for example, will ride bumpier in surface chop if left trimmed at calm water angles. With an outboard or stern drive, an operator can control bow attitude its tilt and trim feature, but it’s trim tabs that let a captain make side-to-side adjustments.

The Right Type

Adjustable trim tabs come in two types: hydraulic and electromechanical. Which style is best is typically a matter of personal opinion, however there are pros and cons associated with each.

Hydraulic trim tab planes are controlled by hydraulic cylinders that are actuated by a hydraulic pump. The pump, motor and associated equipment for the entire system is installed inside the boat in a dry, more-protected environment. On the downside, because they require the installation of a hydraulic pump and hoses, hydraulic trim tabs are a bit more complicated to install than electromechanical systems — although not overwhelmingly so.

Electromechanical trim tabs utilize electric actuators to move trim tab planes up and down. Because the actuators immediately stop and start when the control switch is pressed or released, they can provide instant response times and precise control.

In an electric trim tab system, everything (electric motor and gear system) is located on the outside of the transom. This simplifies the installation somewhat, but it also runs the risks associated with having electronic components underwater.

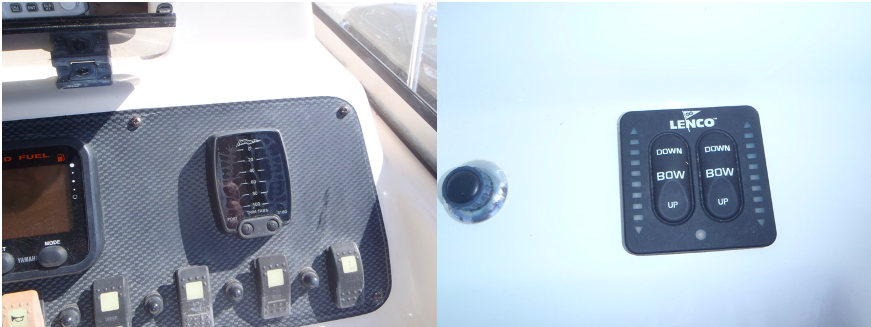

Both systems utilize an electronic control switch or joystick located at the helm. Pressing the switch or toggling the joystick generates an electrical pulse. This energizes the hydraulic pump or electric motor for the trim tab planes (depending on which system is installed).

The trim tab planes themselves come in a variety of sizes. Trim tabs for high-speed boats tend to be long and narrow, while smaller, slower boats will generally use wider, shorter planes. The best way to select the proper size for a boat is to consult with the trim tab manufacturer.

Installation

While having trim tabs installed by a dealer or boat yard is a common option, the installation is well within the ability of any competent DIYer. As with any installation, the trick is to read the installation instructions and understand them completely prior to picking up that drill. A typical installation should take around five hours, depending on the boat.

Rules to Trim By

While everyone should follow the instructions provided by the trim tab manufacturer, the following general tips can be applied to most any installation.

When determining the location of the trim tab planes, keep in mind that the farther out the tabs are from the hull centerline, the more effectively they will operate. Also, make sure both tabs are symmetrical — i.e. mirror images on each side.

While determining the location of the trim tabs and actuators, verify there are no obstructions inside or outside of the transom that will interfere with the installation. This includes double-checking that an installer will not be drilling into hoses, equipment or wire runs.

If the boat has an outboard or stern drive, verify that the trim tab locations are located outside of their steering angles.

When drilling, run the drill in reverse until through the gelcoat (to help prevent chipping) then switch to forward and continue drilling. Beveling each hole will help prevent future gelcoat cracking and provides a better seal once caulking is applied.

If the transom is solid fiberglass, drill the holes for the mounting hardware and use a good quality, marine-grade sealant during the final installation. For a cored transom, seal the exposed coring with epoxy resin to prevent water intrusion into the core. Alternatively, one can also drill the mounting holes slightly larger than needed, fill them with thickened epoxy, then drill the properly sized hole through the epoxy plug when cured.

Once all holes are drilled, dry-fit everything to ensure a perfect fit prior to bedding (caulking) and final installation.

By Capt. Frank Lanier

Captain Frank Lanier is a SAMS® Accredited Marine Surveyor with over 40 years of experience in the marine and diving industry. He’s also an author, public speaker, and multiple award-winning journalist whose articles on seamanship, marine electronics, vessel maintenance and consumer reports appear regularly in numerous marine publications worldwide. He can be reached via his website at www.captfklanier.com