Access More Boat Tests

Already have an account? Login

Monte Carlo Yachts Most Precious Secrets

Captain's Report

Monte Carlo Yachts Most Precious Secrets

Behind the MCY Success

Monte Carlo Yachts Yard

Welcome to the Monte Carlo Yachts Yard in Monfalcone, Italy, a place where game changing innovation and tailor-made design have come together to create a new groundbreaking concept in the world of luxury yachts.

Over 400 people work in the MCY shipyard, and they're all committed to the same goal: creating beautiful and functional yachts with remarkable sea faring qualities.

Design

Each yacht in the MCY collection is designed by the world famous Nuvolari Lenard Studio, located just short distance from Venice. Together with Carlo Nuvolari and Dan Lenard, Monte Carlo Yachts has redefined the meaning of words such as style, functionality and customization.

At the Monte Carlo Yachts state-of-the art shipyard, each project takes shape in an open space concept office, where engineers and designers work side by side with marketing and sales departments.

Efficient collaboration between our teams allows us to welcome customer requests and quickly turn them into reality. What may come to a surprise at first is discovering that Monte Carlo Yachts builds fiberglass boats where virtually every inch of space is custom-designed and hand-made.

We aim to offer exceptional quality, enjoyment and livability on board. To this end, all materials used in our yachts' living spaces come from the world’s top design firms.

Leveraging technology both within the design and manufacturing process, the MCY collection offers limitless customization possibilities to satisfy any owner's special requirements.

Monte Carlo Yachts has gone beyond a truly iconic design and remarkable customization capabilities by introducing a revolutionary naval architecture and unique modular construction process.

Naval Architecture and Production Process

Inspired by Lean Manufacturing concepts and the aerospace industry, our manufacturing process constitutes an extraordinarily innovative approach in the yachting sector.

Let's discover what makes it so special.

All fiberglass components of every MCY yacht are meticulously manufactured using engineered core materials and resin applied by vacuum infusion. This choice provides for a better work environment thanks to adrastic reduction in the levels of emissions in the air. While also reducing the yacht's weight through an optimization of the impregnation ratios of the composite.

In addition, light core materials and aluminum structures replace most of the elements in fiberglass composite, offering strong and lightweight elements that provide improved performance and greater fuel efficiency.

Almost unique in the sector, all fiberglass components used receive a special post-curing treatment before going to the assembly line, guaranteeing the best mechanical and physical properties.

This procedure is performed inside the company's state-of-the-art painting facility which doubles as an oven running high temperature, post-curing operations.

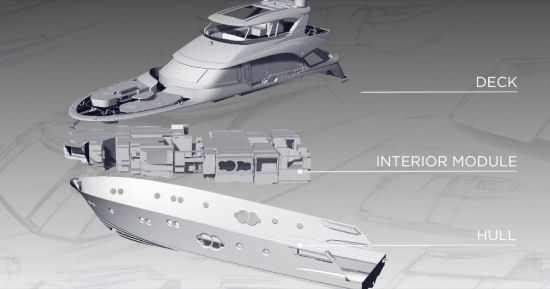

MCY yachts are made of three modules - HULL, INTERIOR MODULE AND DECK - which are built simultaneously until the last detailing stage then joined together during final assembly.

The truly innovative element is represented by the interior module, which is built in its entirety as a single piece out of the hull.

The traditional hull structure is replaced by an innovative internal structural skeleton so that the entire beam of the yacht contributes to increase the structural qualities of the boat. This structural concept becomes the essential element that makes modular construction possible.

Our lean manufacturing production process is applied to the entire MCY collection, which gives us tremendous advantages in terms of creating higher quality boats and saving production hours. A totally different way compared to the rest of the market both in terms of process and naval architecture.

The Hull

Let's start exploring the HULL.

The hull of every MCY presents itself as an extremely solid, light shell, with top-of-the-category safety standards certified by RINA. Characteristics made possible by the modular approach together with the use of self-supporting plating made in sandwich, longitudinal reinforcements, a bow crash box, and extensive use of Kevlar and carbon fibers.

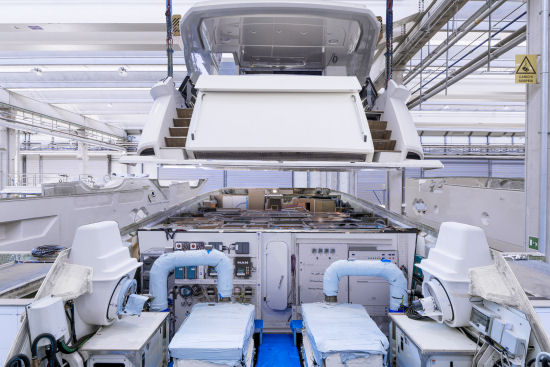

All main electrical and hydraulic systems that are strictly linked to the hull, as well as water and fuel tanks and the engine room equipment, are assembled during this phase.

Main engine room bulkheads are insulated with composite insulation materials that serve to absorb a large portion of engine noise and also reflect heat back into the engine compartment where it can be dissipated with the engine room blowers.

Engine mounts sit on top of the stringer system and are secured with bolts that are drilled and tapped into steel plates laminated into the tops of the stringer members. When all the electric and hydraulic systems together with the entire engine room set up are completed, the hull is ready to welcome the interior module.

The Interior Module

As mentioned earlier, construction is developed in parallel and the entire interior module is built out of the hull.

The entire structure of the interior cabins is conceived in modular form on a grid system so it can be readied outside the hull in complete control of the assembly tolerances, now limited to around a millimeter. This system makes it possible to care for the smallest design and decor details allowing total accessibility in the preparation of the on-board systems.

Soft mounting solutions are applied to limit the transmission of vibrations and noise toward the interior rooms, providing excellent comfort and reliability standards.

The innovative architecture of the boat coupled with our industrial process enable us to customize layouts offering almost limitless possibilities for personalizing the end product without the need to start designing each yacht from scratch.

Every piece of hardware installed onboard has been carefully selected for form, function and durability. The complete design and production of the furniture is made in-house utilizing only natural wood, a solution which enables to obtain unparalleled levels of quality and finishing.

Natural stone, hand-made tiles, decorative metals, hand-stitched leather and high end fabrics are selected from the best Italian suppliers and assembled inside the MCY facilities.

Each of these materials is cut, shaped, sanded, finished and installed as a piece of a larger, more complex creation. Every bulkhead receives its own special covering and every cabinet was designed and built for a specific purpose and to hold designated articles.

The Deck

The third module is the deck, which is built separately from the other elements and joined with the superstructure, the flybridge framework and the carbon fiber t-top. The fiberglass components are entirely made by infusion and characterized by Kevlar and carbon fiber reinforcements to increase structural reliability, contain weight, and reduce roll amplitudes to increase onboard comfort.

The deck itself is finished with exterior teak decking, stainless steel equipment, and double-glazed windows and windscreens. Even the underside of the deck, an area typically not seen by the most, is fully finished and covered by composite insulation materials.

Extensive use of pre-assembled components guarantees a much faster complete fitting of the deck, including all the electric, electronic, and domotic systems together with indoor and outdoor fixed deck or free standing furniture.

Final Assembly

Once each of the three big modules - HULL, INTERIOR MODULE AND DECK - are fully completed and equipped, it is time to join them together in a sort of "plug and play" operation.

During this fundamental phase, the first elements to be joined are the HULL and INTERIOR MODULE. The entire interior module is lowered into the hull in a single action and joined utilizing special structural glues adopted from the aeronautical and automotive sectors. The overall procedure is accurately planned and performed in just a few minutes.

At the end of this first step, the interior lower deck rooms perfectly fit the hull and are integrated in complete control of the assembly tolerances limited to a few millimeters.

Next comes the joining of the HULL and DECK modules. As for the previous step, specific structural glues are used to guarantee the yacht's structural integrity and maximum reliability in complete control of the assembly tolerances.

Painting and Commissioning

Once this phase is complete, and the yacht undergoes all of Monte Carlo Yachts' rigorous quality control inspections, it is ready to enter the company's state-of-the-art painting facility.

The hull finally receives its rich, glossy outer coat of paint. Owners have almost limitless choices, including custom-made colors. For the next 24 hours, the boat stays in this climate-controlled oven until the paint has set.

The yacht will then go through a series of accurate tests before its final handover to the customer. Prior and during specific sea trials, all equipment and machinery will be thoroughly tested for a length of time sufficient to demonstrate satisfactory workmanship and operational suitability.

Commissioning tests will ensure that the equipment performs well technically, but will also make certain the whole yacht will perform flawlessly in challenging sea conditions.

Applied to each model in the MCY collection, this unique manufacturing process has undergone continuous improvements over the years. Monte Carlo Yachts' disruptive improvement has been awarded with the Innovation in a Production Process Award at the IBI-METS Boat Builder Awards.

"Monte Carlo Yachts' modular construction system is a game-changer for the industry.

Ultimately, Monte Carlo Yachts' ability to construct interiors outside of the boat on a grid system not only greatly simplifies the build process, but also encourages more exact levels of finish, allowing much greater levels of customization.

In essence, Monte Carlo Yachts has cracked the code of building semi-custom boats on a full scale series production line. Its collection bares testimony to a builder redefining the rules."

Monte Carlo Yachts.

We create Future, Classics.