ElectroSea ElectroStrainer System

Keep Your A/C Cool, Keep Your Strainer Clean, and Never Descale Again!

Marine air conditioners are an essential part of summer yachting and boating in the Tropics almost year-round. But keeping the systems functional presents some problems not found in the AC systems all of us are familiar with at home and at work.

The reason?

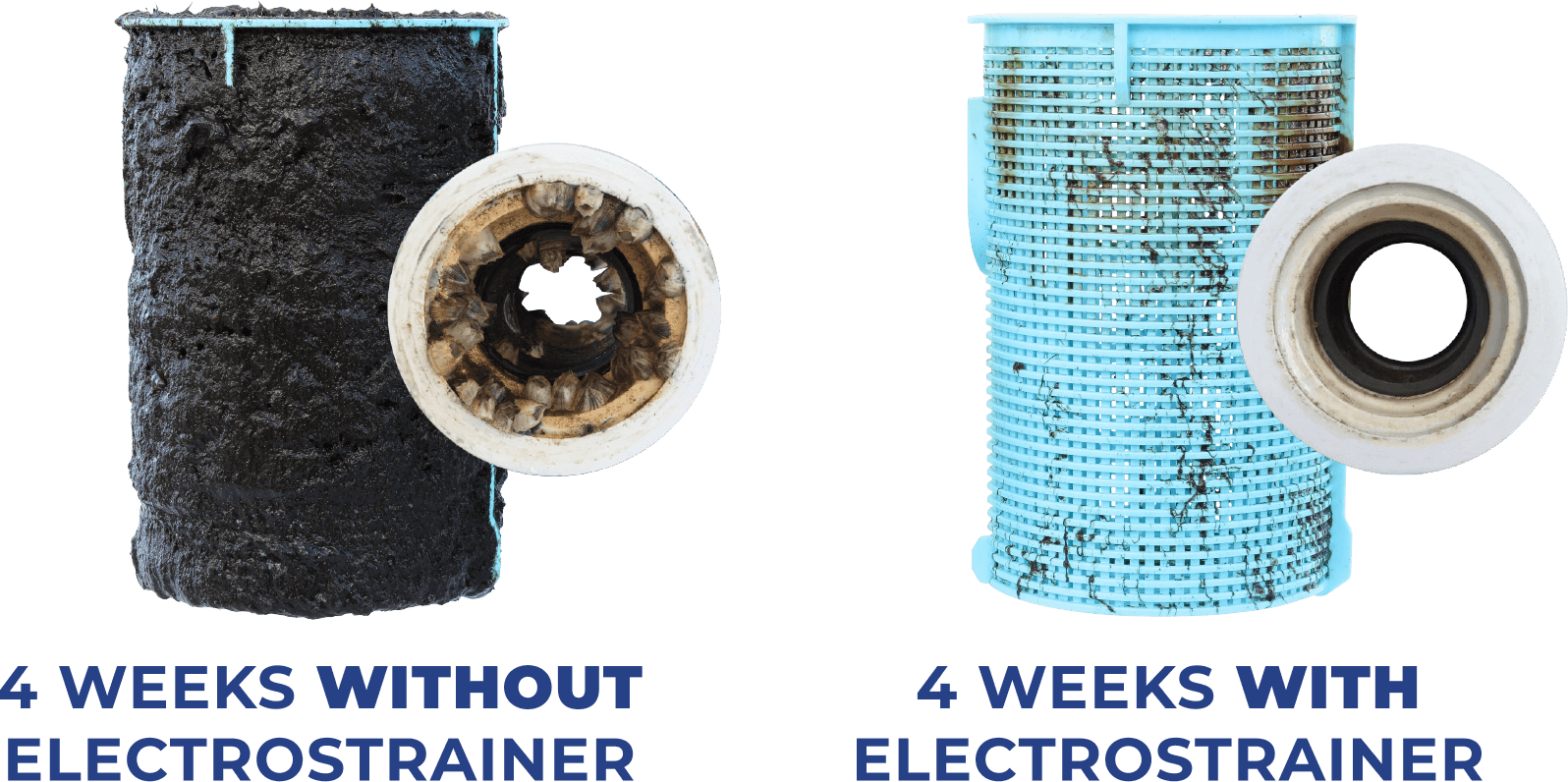

Marine ACs are water-cooled, and water in coastal areas contains minute offspring of barnacles, oysters, mussels and other hard-shelled organisms. They’re programmed to latch on to any hard structure they contact, settle in and start to grow. And they grow very rapidly.

Algae, slime and other soft growths can also accumulate, clogging the pores of the sea strainer basket and restricting water flow.

Unchecked, enough of this “biofouling” can accumulate inside the cooling passages of a marine air conditioner’s heat exchange system to reduce the flow. Best case, this reduces cooling efficiency — you don’t stay as cool as you expect.

Worst case, your AC overheats and has to be rebuilt or replaced, a very costly repair.

Traditional Cleanout: Risky and Environmentally Harmful

The traditional solution is regular cleaning via high-pressure rinse, scrubbing and scraping of the strainer basket on the sea-water supply line, as often as every 2 or 3 weeks in warm, high-growth areas.

In addition, the system must be periodically "acid descaled" with a chemical agent, commonly phosphoric or muriatic acid, multiple times every boating season. But this is a process that can decrease the life expectancy of your air-conditioning system and progressively eat away at joints in the plumbing.

It’s also potentially harmful to service technicians, crew and the environment.

Placing pool chlorine or bromine-high test hypochlorite tablets (HTH) into the sea strainer basket also works, but the chlorine level cannot be regulated, and again there’s potential environmental harm in the outflow.

ElectroSea® has a better solution with their ElectroStrainer® system, which requires almost no attention throughout the boating season, presents no risk in servicing and does not harm the environment.

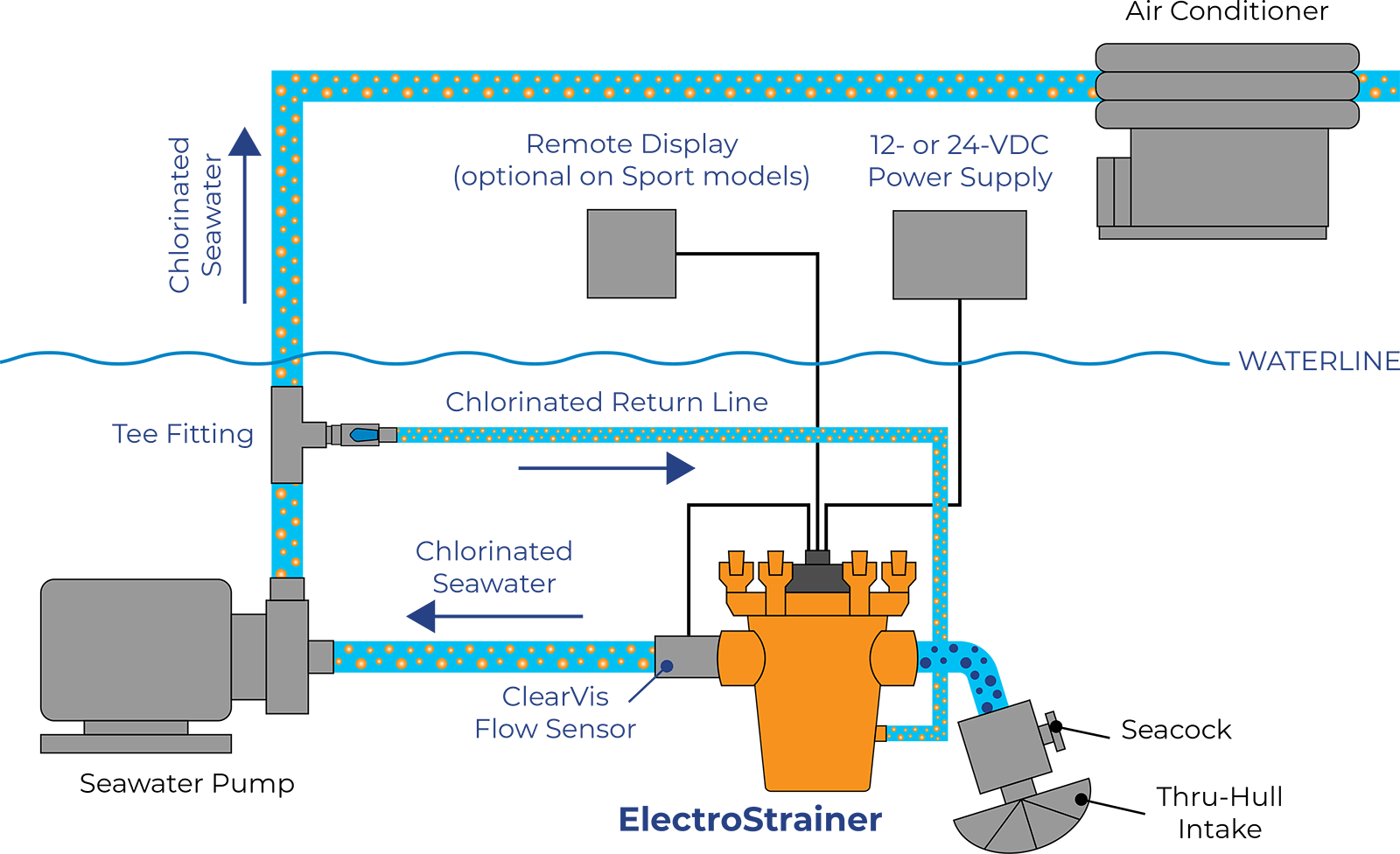

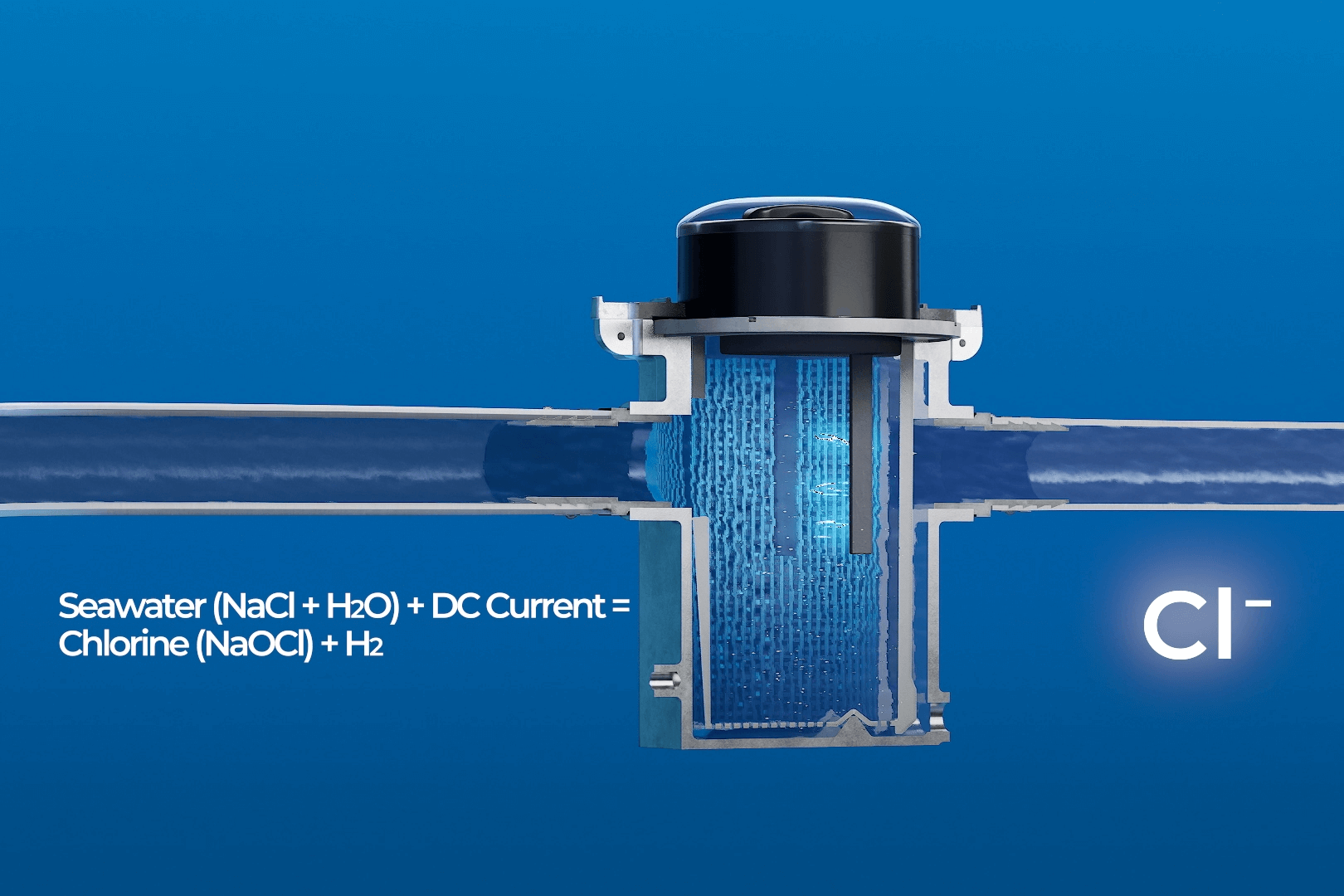

The ElectroStrainer is plumbed directly into the water supply for any raw-water-cooled device, replacing the existing sea strainer. ElectroStrainer generates a consistent, low level of chlorine – lower than you’ll find in tap water, but enough to keep barnacles at bay. There are NO chemical additives or acids required.

Continuous, low-level electrochlorination is a proven anti-fouling treatment that controls the growth of a range of marine organisms, including barnacles and biofilms. Chlorinated seawater exhibits rapid decay and has a very short half-life with two-thirds decomposing back into common salt (sodium chloride) and water in about one minute. The seawater that exits the boat is not harmful to the environment.

No scheduled maintenance is required, and the monitoring system alerts the user if the flow ever begins to fail, indicating the filter basket or other component has issues.

Marine growth prevention that’s right for you

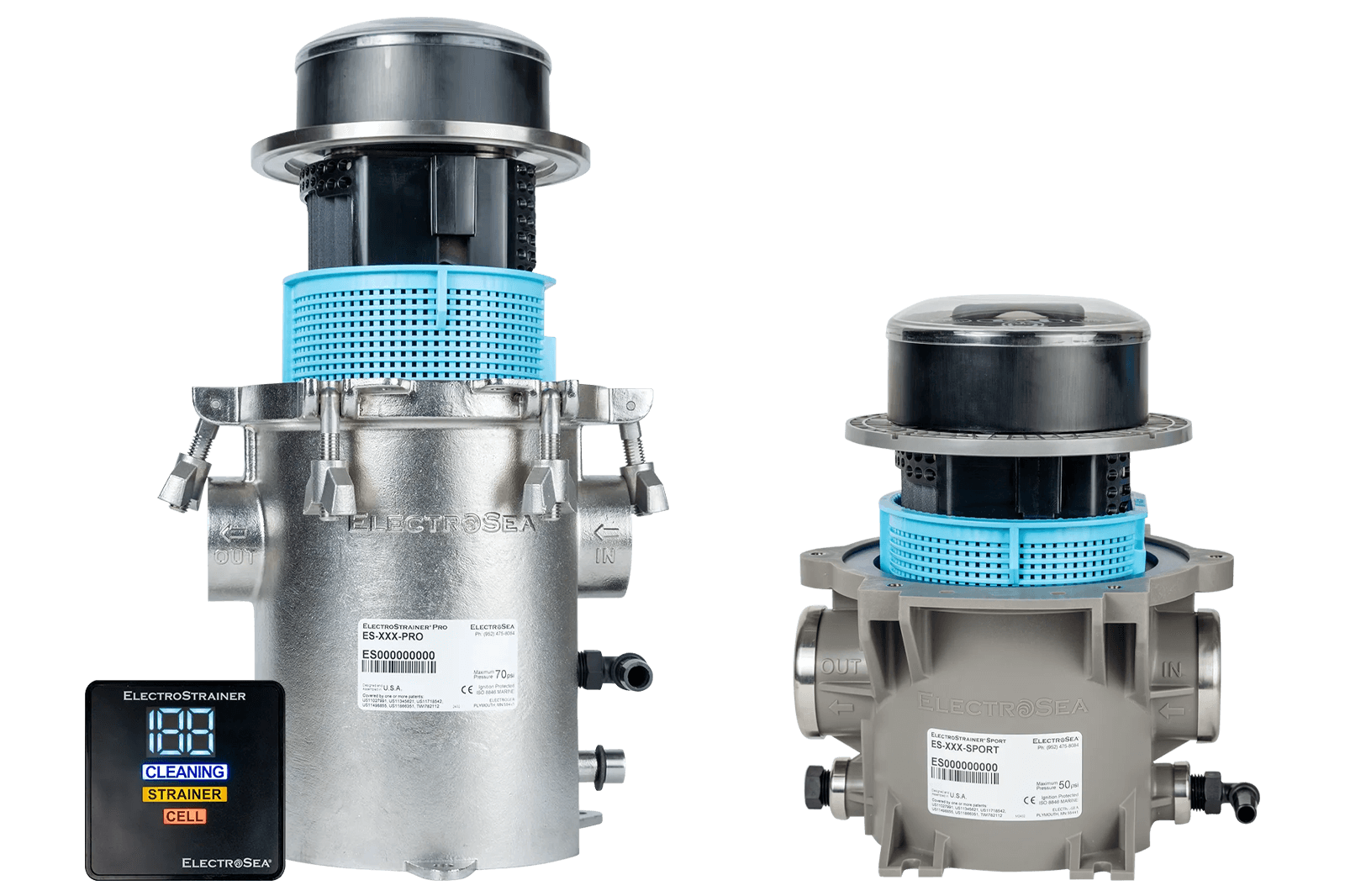

ElectroSea offers two options for all-in-one marine growth prevention – ElectroStrainer® Pro and ElectroStrainer® Sport. ElectroStrainer Pro is available in four strainer inlet/outlet sizes with optimal flow rates up to 40 gpm. Available both for new build and refit installations, ElectroStrainer Pro is the ideal choice for those seeking the ultimate in quality and reliability.

ElectroStrainer Sport is designed for those looking for an entry-level, refit option. ElectroStrainer Sport is available for refit in two strainer inlet/outlet sizes with flow rates up to 17 gpm. Designed for easy self-installation, ElectroStrainer Sport is ideal for budget-conscious consumers looking to experience the benefits of ElectroStrainer at an affordable price.

The remote display (optional on ElectroStrainer Sport models) not only tells you when the unit is cleaning but also measures the flow rate through your system so that you can head off problems early.

For details, visit https://www.electrosea.com/electrostrainer.