Sharrow Propeller™

The Sharrow Propeller™ is a remarkable new, patented loop propeller design that CEO and inventor, Greg Sharrow, claims can out-perform conventional propellers in most major parameters of current propeller measurement. The propeller was developed over 7+ years by Sharrow Marine, a Philadelphia-based nautical and aeronautical design firm.

Sharrow Props 46% More Fuel Efficient at 18 Knots on 300-hp Diesel Engines

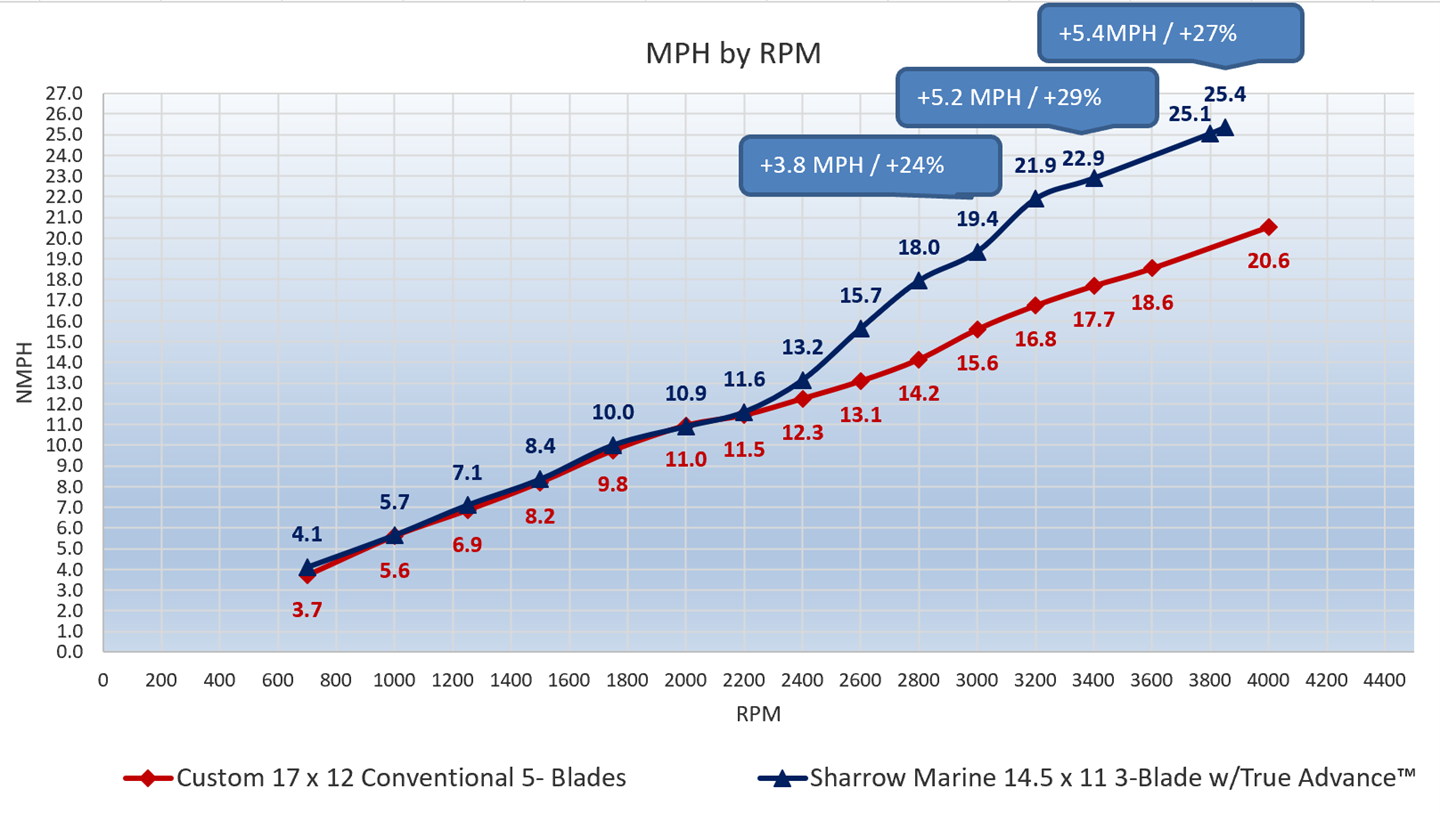

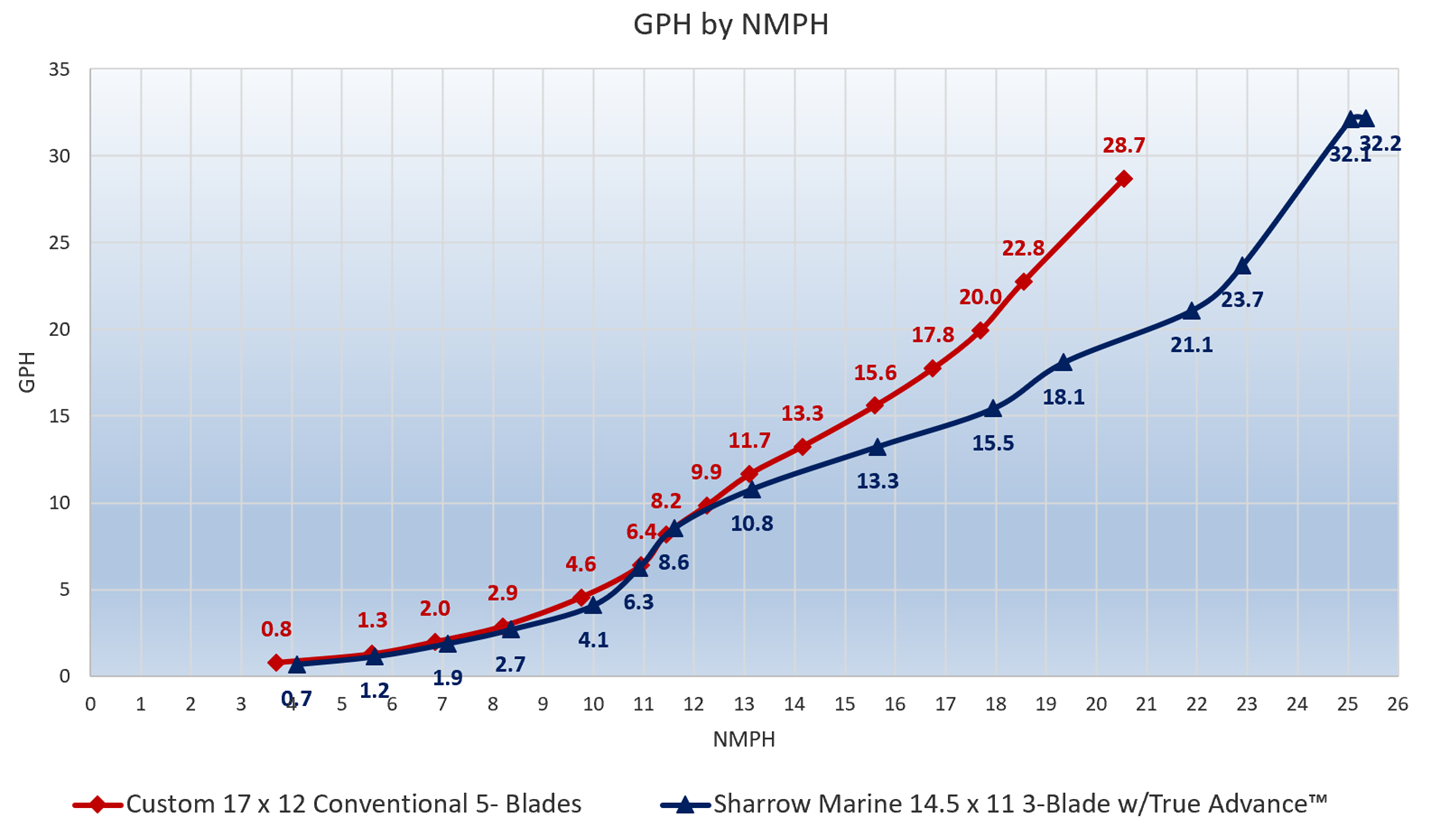

Recently, BoatTEST evaluated a 57’ (17.37 m) catamaran, Voodoo, powered by a pair of 300-hp OXE diesel outboard engines. We ran her with custom Sharrow props and conventional 5-blade wheels made by one of America’s best outboard prop manufacturers. This was a particularly important test because there are now two brands of outboards being made for heavy-duty commercial, military, police and heavy recreational boat applications.

Other Diesel/Sharrow Prop Applications

A cursory look at other catamarans of about 40,000 lbs. (18,181 kgs.) powered by inboard diesels, both straight shaft and pod-driven, indicates that 300-hp diesel outboard engines equipped with Sharrow props are likely to be significantly more fuel efficient. Many charter fleets around the world are turning to diesel-powered cats, which means they will have the same downtime threats that the owner of the boat we tested faced — and that’s why he turned to outboard diesels.

Prop Showdown Bottom Line

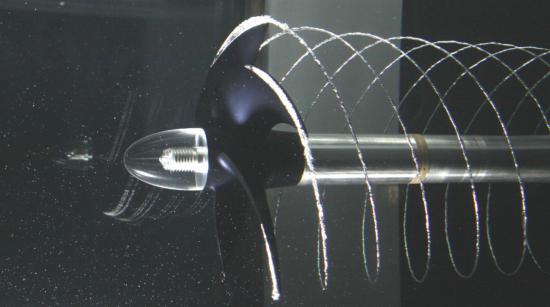

Virtually all gasoline outboards we have tested have ‘through-the-hub” exhaust. As a result, our test captains could never determine how much of the frothy bubbles emanating from the whirling prop was exhaust and how much was cavitation. But, because the OXE diesel does not exhaust through the prop hub, for the first time we could see the cavitation of a conventional 5-blade prop.

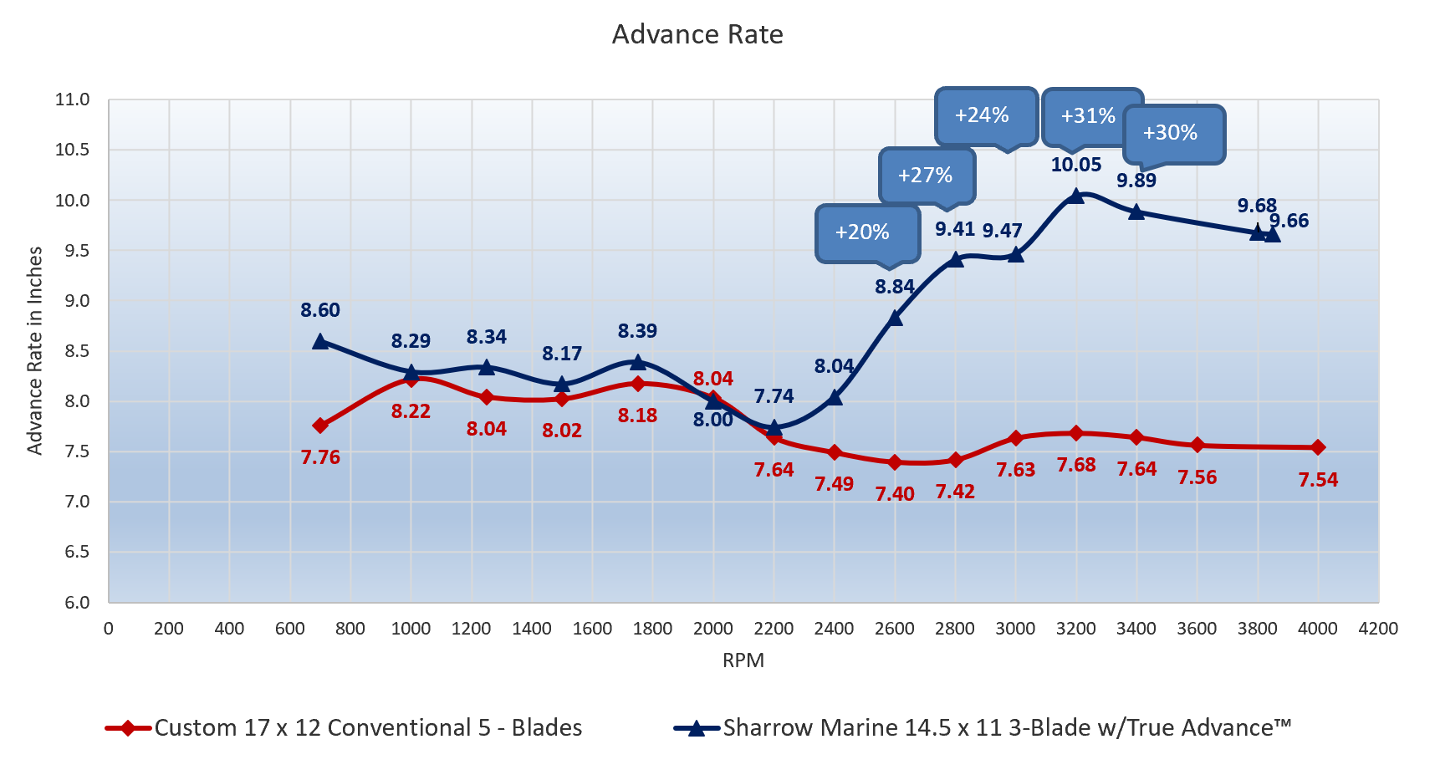

The result of the cavitation was that the advance rate of the 17” (43.18 cm) diameter x 12” (30.48 cm) pitch 5-blade conventional prop advanced only 7.40” (18.8 cm) to 8.22” (20.88 cm) with every 360-degree rotation of the prop. On the other hand the Sharrow prop advanced from a low of 7.44” (18.9 cm) to a high of 10.05” (25.53 cm) with its 14.5” (36.83 cm) x 11” (27.94 cm) 3-blade prop. See the chart below.

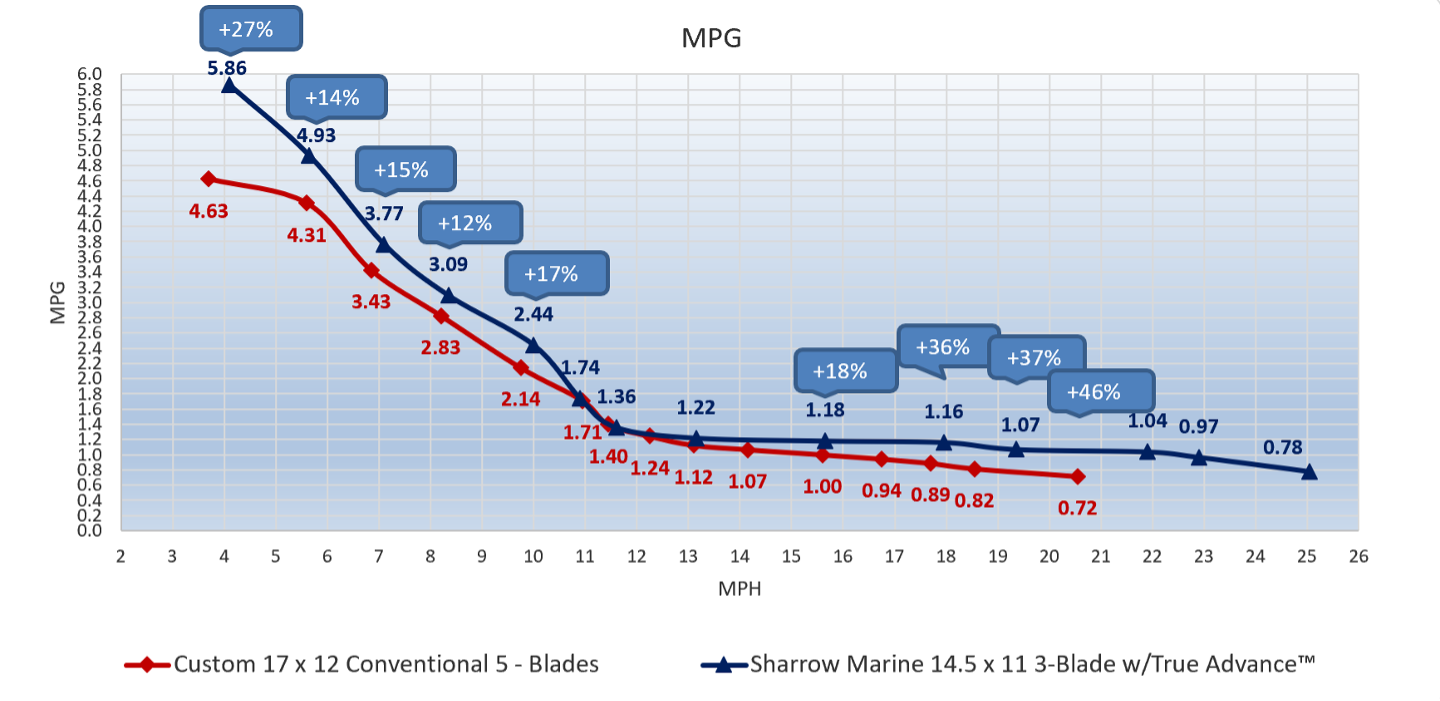

Because the boat was advancing from 20% to 30% farther with each rotation of the prop with the Sharrow prop, it was naturally the most fuel efficient of the two designs at all rpm settings except one. Studies conducted by the world governing body of the boating industry (ICOMIA), showed that powerboats are used 40% of the time at idle. At that speed, the Sharrow prop was 27% more fuel efficient than the traditional design.

The greatest improvement in efficiency was precisely where the boat’s owner said he ran the boat most of the time — at 18 knots. For that reason, we were told, the Sharrow engineers dialed in the greatest prop efficiency at 18 knots — the 46% improvement in fuel efficiency at that speed was no fluke.

Our test of the two props was one of new technology vs. old technology. In fact, the conventional props used today are basically the same designs as the first ones that were invented in the 1830s. After nearly 200 years man has finally improved on the propeller concept.

In the content below, you will find the results of our tests on other boats comparing Sharrow props with old technology. The results are always the same.

Testing Sharrow Props on a World Cat 325 DC

Two years ago, BoatTEST evaluated a radical new propeller from Sharrow Marine. Its unique loop-blade design was revolutionary and we were intrigued. We compared an aluminum version to two stainless-steel propellers on a 20’ (6.1 m) bowrider that weighed 3,453 lbs. (1,566.25 kg) and was powered by a 150-hp Mercury four-stroke outboard. (See the report below for full details.)

In short, we discovered that the Sharrow was faster at all rpm settings, planed with less rpm, had more reverse thrust, gripped the water better in turns and had better mpg readings at nearly every speed, particularly in the midrange.

Some wondered if we just found the sweet spot for that prop in that outboard-powered bowrider.

Round Two

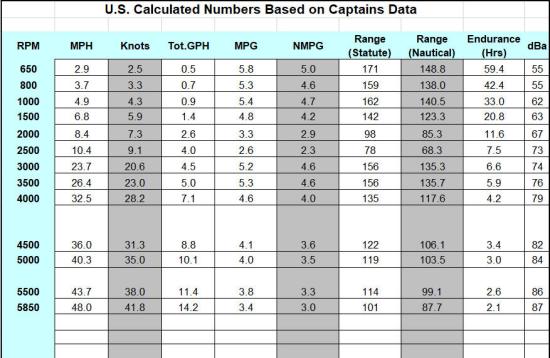

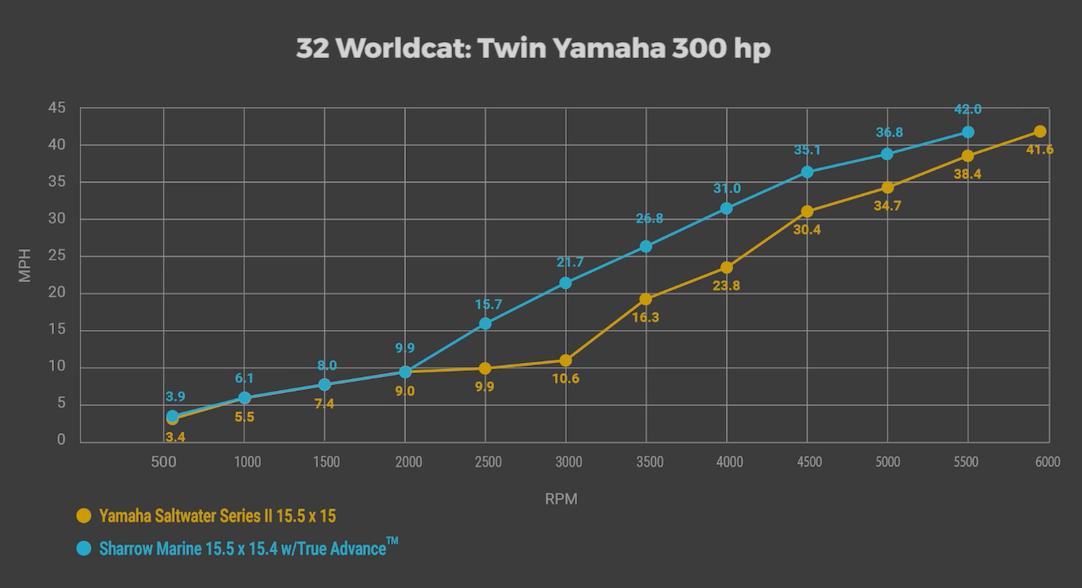

To answer those questions, Sharrow commissioned BoatTEST to run a second evaluation of its propeller, this time on a 32’2” (9.8 m) World Cat 325 DC catamaran powered by twin 300-hp Yamaha outboards. With three people, fuel full and test gear aboard, our test model had a weight of 13,694 lbs. (6,211.49 kg).

We put the boat through the same test procedure we use for every performance test we conduct, taking speed, fuel consumption and decibel readings in opposite directions at 500-rpm intervals. First, we ran the boat with the propellers recommended for the application by the boat and engine manufacturers, Yamaha’s Saltwater Series II stainless-steel 15 3/4” x 15” (40.01 cm x 38.1 cm) three-blade propellers turning in the standard rotation.

Real-World Testing

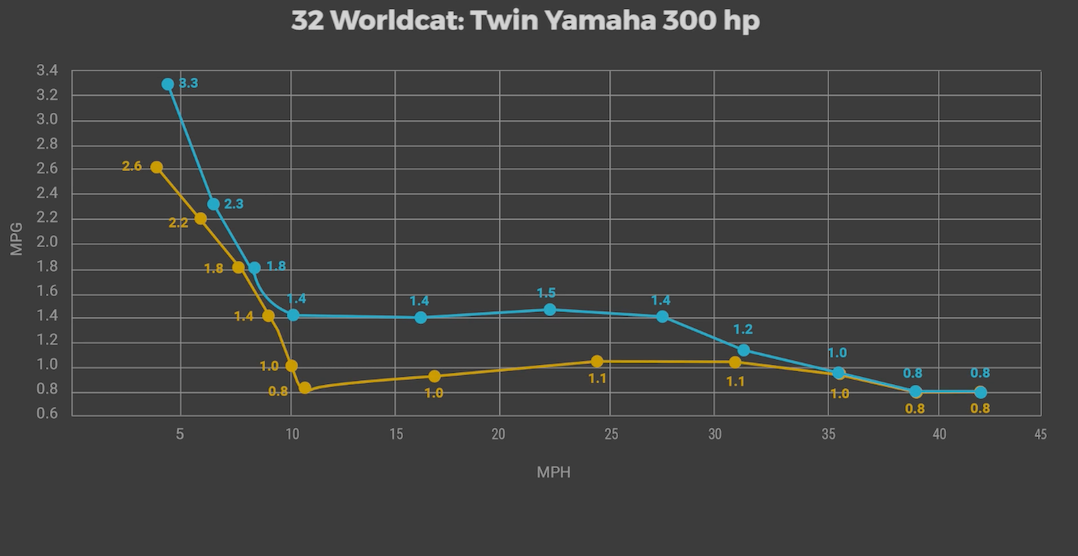

Because the average boater spends about 60% of his/her time running in the mid RPM range, we’re starting by focusing on best cruise, which we define as planing speed with the greatest range. For our test boat, we found best cruise at 4000 rpm where she ran 23.8 mph and burned 21.2 gph. This translated to 1.1 mpg and a range of 282 statute miles while holding 10% of the 32 DC’s 279-gallon (1,056.13-liter) fuel capacity in reserve.

With all the data acquired with the stock propellers, we hauled the boat and put on 15.5” x 15.4” (39.37 cm x 39.12 cm) three-bladed Sharrow stainless-steel wheels, topped off the fuel and headed back out on the water with the same test crew. Conditions remained consistent for our second test.

With the Sharrow props, which were designed specifically for our test boat, we found the 325 DC’s best range at 3000 rpm where she ran 21.7 mph, burned 14.8 gph and wrung 1.5 miles out of a gallon of gas. This gave her a range of 368 statute miles with the same 10% of the boat’s fuel capacity held in reserve.

Noteworthy Differences

Looking at the results, the Sharrows’ most economical rpm was 1000 revs lower than the stock propellers and the boat ran 2.1 mph slower. The biggest difference was the fuel consumption. With the conventional wheels, the boat burned 21.1 gph, but with the Sharrows, that number dropped to 14.8 gph. That translated to 1.5 mpg for the Sharrows compared to 1.1 mpg with the stock props, a 36% advantage.

Our test boat's range also increased to 368 statute miles, which is 86 miles farther than the stock setup. For anglers heading out to the canyons, that’s worth a closer look.

Taking a look at some other numbers, at idle, the Sharrow props were 24% more fuel-efficient. The international maritime agency ICOMIA estimates that a boat spends 40% of its duty cycle running at idle, so this could be important over time.

All-Important Fuel Efficiency

Working our way up the power curve, at 10 mph, the efficiency of the stock propellers drops to .8 mpg because the boat is trying to break over its bow waves and get on plane, but can’t do it at 2500 rpm. At the same rpm, however, the Sharrows planed the boat at 16 mph and burned was getting 1.4 mpg of fuel, which is nearly at peak efficiency and 75% better than the stock wheels.

At 20 to 25 mph, the Sharrows maintained an advantage of 36% in miles per gallon and at 35 mph, the efficiency for both sets of propellers evened off. At WOT with the Yamaha propellers, we hit a top speed of 41.6 mph at 5900 rpm where we recorded 52.4 gph. With the Sharrows, we hit 42 mph at 5500 rpm and burned 53.9 gph. Both of these sets of figures were calculated to .8 mpg and nearly identical range.

Which Props are Quicker?

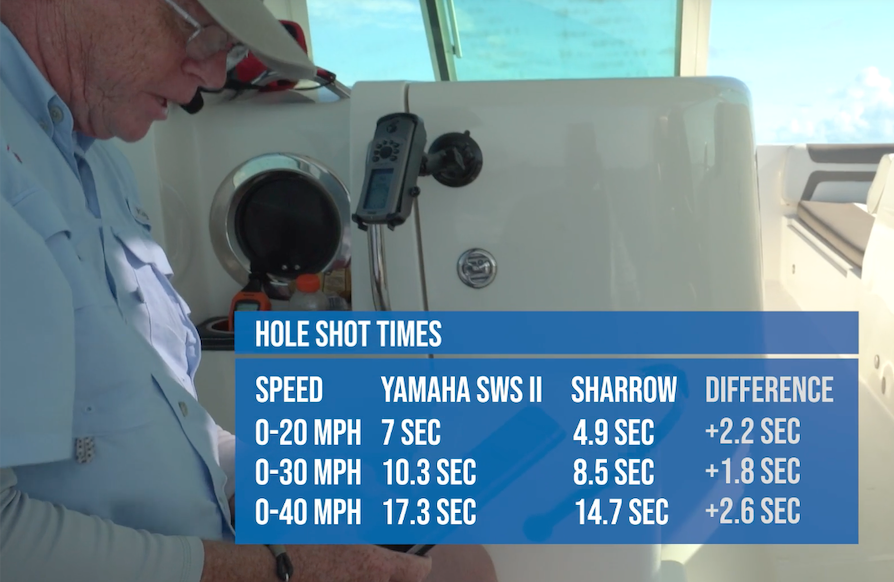

Because time to plane can be a highly subjective test number, we stayed with tracking acceleration through specific mph settings. From zero to 20 mph, the Sharrows were 2.2 seconds quicker. They maintained their advantage through 30 mph (1.8 seconds) and 40 mph (2.6 seconds).

In summary, the Sharrow propellers planed solidly at 3000 rpm and were faster at all rpm. Capt. Steve felt they had more thrust in reverse, which improves low-speed maneuverability for a tall boat like the 325 DC. They also maintained their grip in tight turns and we felt less vibration across the power curve.

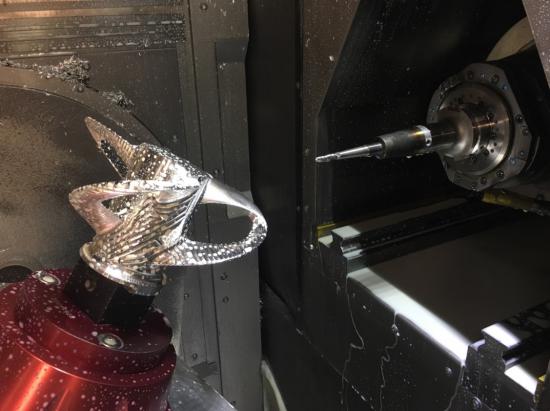

Sharrow Prop Production for 2022

Greg Sharrow, the propellers’ inventor, has made agreements with three foundries in the U.S. Midwest to cast his props. His company is currently planning on doubling the number of CNC 5-axis routers needed to finish the props to within a tolerance of.003, something nearly impossible to achieve with standard-design cast props. He is planning on casting 10,000 props next year.

Because the Sharrow props are designed for each specific engine and its gear ratio, Sharrow plans to cast the same 15.5" x 15.4" (39.37 cm x 39.12 cm) props used on the twin Yamaha 300s in this test.

About Sharrow Propellers

- The Back Story

- Design & Testing

- Manufacturing

- Testing by the BoatTEST Team

- Test of Propeller #1

- Test of Propeller #2

- Test of Propeller #3

- Comparisons

- Sound and Vibration

- Testing Summary

- Early-Adopter Registration Form

- Observations

The Remarkable New Sharrow Propeller™ Model MX-1

The Back Story

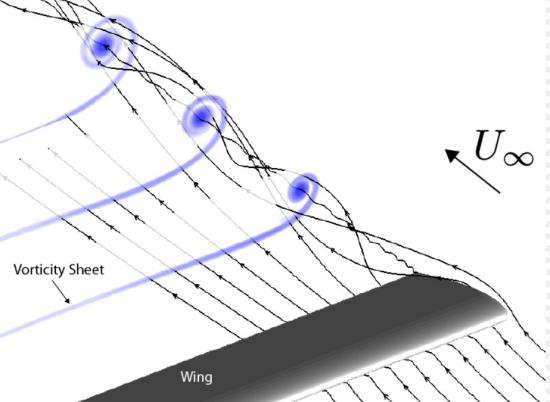

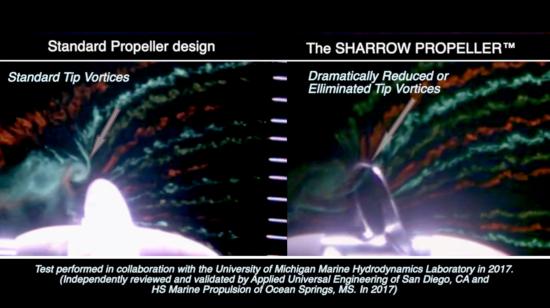

Inventor Greg Sharrow did not start out to create a new kind of propeller. Instead, this Berklee College of Music graduate, who was working as an Executive Producer and Director in the video production field, originally set out on a mission to develop an ultra-quiet drone for use in the entertainment industry and for military purposes, where noise is a critical factor. By dramatically reducing or eliminating tip vortices, Greg knew he could significantly reduce the noise that is produced by propellers when compared to conventional blades.

Greg knew the key to dramatically reducing or eliminating the tip vortices in the most extreme way possible meant eliminating the tip itself. But how could you make a tip-less propeller? What would it look like and how would it function?

During a daily morning walk, after a day of pondering these questions, the idea for the Sharrow Propeller™ came to him and he immediately understood the benefits of the novel design, he says. “It’s a propeller that not only dramatically reduces or eliminates tip vortices and tip cavitation, but it also has many other benefits, including reduced noise and vibration." After that “ah-ha” moment, he began assembling the legal team, engineering team, partnerships and funding for the massive R&D effort that would come next.

During the R&D and design process, Greg and his team of engineers discovered many other advantages of the Sharrow Propeller™ across a range of applications and fluid densities, but the original inspiration came from Greg’s desire to make a quiet drone.

Aeronautical engineers and naval architects had long known that propeller tips created vortices that induced drag, slowed propulsion, and increased fuel consumption. Over the years, many engineers have attempted to design a propeller with modified tip properties that would reduce tip vortices, but none have reduced the number of tip vortices like the Sharrow Propeller™, according to Sharrow.

“It’s been an incredible journey so far,” says Sharrow. “And now, after seven-plus years of R&D, we have 22 patents around the world with many others pending, development and manufacturing partnerships with some of the world’s largest shipbuilders and propeller manufacturers and a product and methodology for generating new designs for different purposes that is simply amazing.”

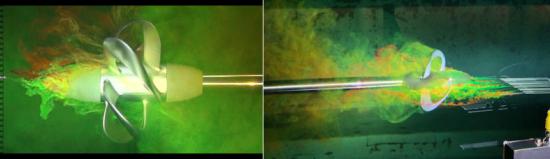

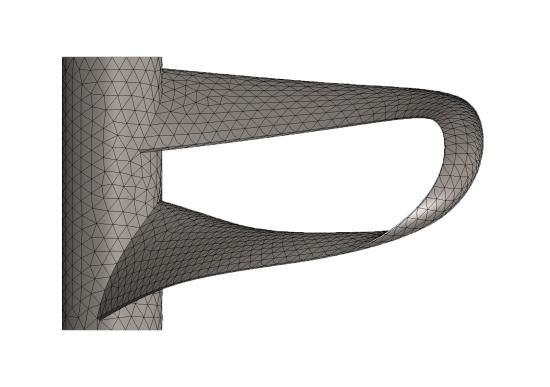

Design & Testing

Using modern computer modeling and additive manufacturing (3D), Sharrow Marine has solved some basic problems of rotary propulsion – including the reduction of tip cavitation and vortices. Their goal is to design new propulsion technologies for the nautical and aeronautical sectors with propellers that exhibit a wider peak efficiency curve for greater utility over a wider scope of operational ranges.

The application for these props is extensive and recreational boating use is only the tip of the iceberg.

The development of the Sharrow Propeller™ has been an extensive process taking a theory of operation, design concept and working models through years of CAD modeling, R&D and testing with reviews by top engineers in the marine and aerospace industries. Sharrow says the process was 1% inspiration and 99% perspiration.

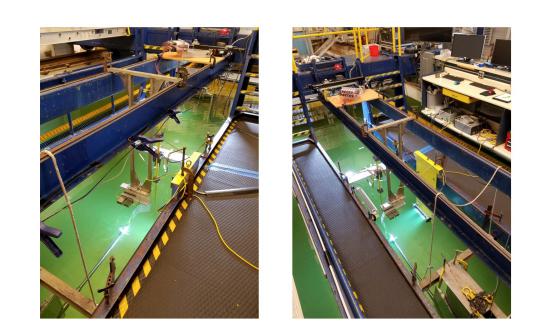

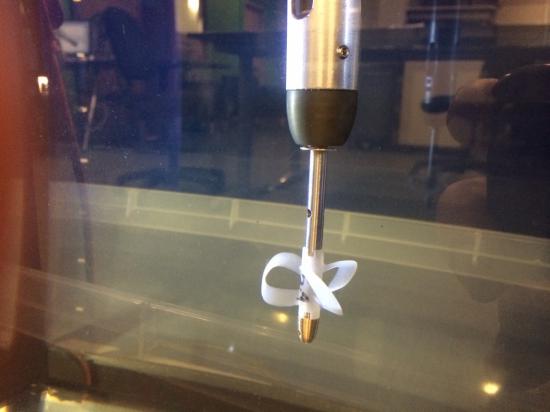

University of Michigan Marine Hydrodynamics Laboratory: In 2013, Sharrow Marine formalized an extensive research and testing program with the University of Michigan’s Marine Hydrodynamics Laboratory (regarded by many as the number one ranked university for naval architecture in the U.S.) to provide insight and independent validation of Sharrow Marine research findings through third-party testing. Here, scale models of the propellers were tested for all sorts of applications to exacting standards.

This relationship with a third-party test facility provided Sharrow Marine with the vital resources to validate numerical models and CFD simulations with physical tests of actual propeller prototypes. Through this R&D effort, Sharrow Marine developed a proprietary method for creating new geometries for a wide range of applications from tugboats, to supertankers, to recreational boats, to planes and drones. “The ‘Closed Loop’ iterative design process is the gold standard for state-of-the-art engineering processes,” says Sharrow.

The most lucrative application of this radical new propeller is on supertankers and other large commercial ships, where it can potentially save them millions of dollars a year in reduced fuel consumption per ship.

Manufacturing

The Sharrow Propeller™ design is a radical departure from conventional propeller designs and seems to be a solution that has long evaded propeller designers. As such, it required an innovative approach to manufacturing as well.

Advanced additive manufacturing technologies played a large role in Sharrow Marine’s development process, particularly for model scale validation testing because, and the design-test cycle was accelerated considerably. Currently, casting patterns come from 3D printed waxes, but 3D printing is still not at the stage where it scales to production volumes. The ability to manufacture very precise high-quality propellers is essential to Sharrow Marine’s testing and manufacturing programs.

Traditional investment casting is used for both prototypes and production versions of the Sharrow Propeller™. Depending on the application and market volume, Sharrow uses the manufacturing process that makes the right propeller for the right application at the best value to the customer.

Testing by the BoatTEST Team

Will this new design concept work on small recreational powerboats? And how will it match up with some of the most efficient conventional props on the market? To find out, BoatTEST sent a four-member team to Detroit, Michigan and spent seven days testing the innovative new design along with two other conventional props to compare their performance.

Test on a 20' (6.1 m) Bowrider with a 150-hp Outboard Engine

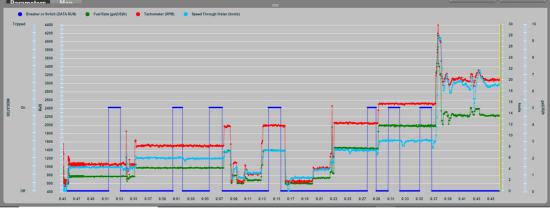

The testing procedure used by BoatTEST was the most rigorous ever used in its testing because when it comes to prop design and performance, even a 1% improvement in prop design is significant. We tested two conventional “benchmark” propellers and the Sharrow Propeller™ by means of long test runs at each RPM. Once we were able to get the boat at a “steady state” we recorded RPM, speed through the water and fuel flow.

These readings came from a conventional speed-through-water sensor installed through the hull of the boat, and from the RPM and fuel flow data that was sent from the Mercury engine to the NEMA 2000 network. This data was recorded in real-time onto an off-the-shelf vessel data recorder. Once a “steady state” was reached after several minutes of traveling at a certain RPM, an indicator switch was triggered by the boat captain for a period of 15 seconds to over a minute. Then, using computer software, the steady-state period was averaged together to give us the results published below.

Our test boat was a 20’ (6.21 m) plain-Jane bowrider with an 8’ (2.43 m) beam like millions of other boats on the water. It had a total tested weight of 3,543 lbs. (1,607 kg), including jack plate, a two-person test team, equipment and fuel.

Our test boat was rigged with Mercury’s fuel flow sensor technology which is extremely accurate, and fuel consumption was displayed on our Garmin screen. Speed through the water data came from a calibrated in-water sensor.

Lengthy Testing Procedure. Perhaps the most important aspect of our testing was the rigor of making sure the test numbers we eventually would publish were as accurate as possible. The boat was in a “steady state” at every rpm setting – and this usually took 10 or 15 minutes to achieve – before we triggered the recording for as long as a minute, and then was averaged.

When performing tests of this type, speed, fuel flow, and even RPM are constantly fluctuating, even in calm conditions. Each little change in the texture of the surface will have its effect on a vessel as light as this one, slowing the speed, calling on a bit more fuel, slowing RPM, then releasing all three to go back to a more normal state.

These days, instruments are so well-tuned, every minute change is seen and must be averaged. This makes sure there are no spike readings up or down, and it is done for RPM, speed, and fuel flow.

We took our performance readings during a “steady state” that lasted, for example, approximately 12 minutes at 1500 RPM. Then, when we visually saw our gauges, what appeared to be average readings, we turned on the recording device, captured the red RPM data, blue speed numbers, and the green fuel flow numbers. The data captures can be seen in the graph above. At some RPM settings, there were two data captures, and that was because we felt that the first one might be flawed, and so a second one was made to ensure accuracy.

After the test, the computer averaged the readings in each period to ensure that the highs and lows were taken out, so a repeatable number could be ascertained.

Our test boat’s fuel tank held 33 gallons (125 L) and the overall full fuel weight was 200 lbs. (91 kg). Our two-person test crew was nearly identical in weight. In any boat, weight is one of the most critical aspects when testing. BoatTEST was careful to top off the fuel tank after every propeller was tested and all other weight aboard the boat was kept the same, propeller to propeller.

Test of Propeller #1

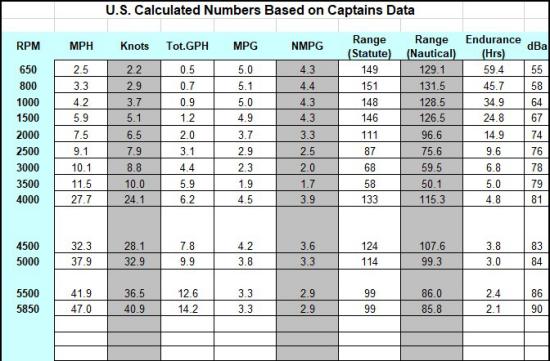

The first propeller we tested was a 14-3/4” by 15” 3-blade stainless steel propeller. It is an industry favorite and has been used for years on thousands of boats both as original equipment and in the aftermarket. It should be noted that this propeller had a diameter ¼” less than the other two. This difference in geometry put it to some disadvantage, but as we will see, it also had its attributes.

Propeller #1 Test Results

Test of Propeller #2

The second propeller we tested was also a premium industry 3-bladed propeller and one known for its fuel efficiency at cruising speeds. Like the first propeller, it’s made of high-strength stainless steel. This one measured 15” Diameter by 15” Pitch. Again, we went from idle to 1000 RPM, and then up to wide-open throttle in 500 RPM increments.

This propeller performed nearly identically to propeller number one, except it got on plane at 3400 rpm, and at 3500 rpm, went 21.2 mph, with a running angle of 2.6-degrees, getting 4.3 mpg for a range of 128 statute miles. This is the major advantage of this propeller vis a vis the first propeller tested – it can get on plane at lower rpm. Note that fuel consumption for the two props is almost identical except at 3500 rpm.

Propeller #2 Test Results

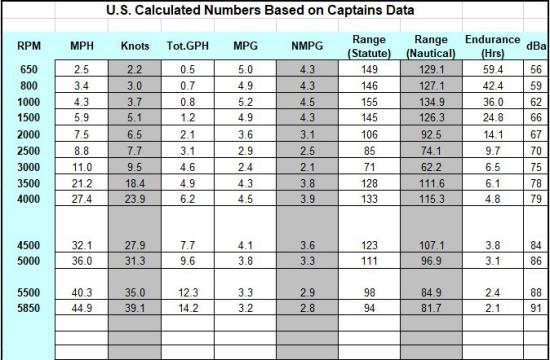

Test of Propeller #3

The Sharrow Propeller™ MX-1 we tested was made by a 5-axis router out of a relatively soft billet of aluminum alloy. Its geometry was 15” x 15”. The very first thing we noticed upon firing up the engine after refueling was the absence of vibration. Three-blade props are notorious for vibration. Since the Sharrow MX-1 was really more like a 6-blade propeller, and one with no open blade tips at that, it was little wonder that the engine now had virtually no detectible vibration. While this aspect of the propeller’s performance was not measured scientifically, lack of vibration was obvious to all.

Handling. After the performance testing, Captain Steve put the boat through his normal handing maneuvers. Then, he conducted rapid, hard-over turning procedures at high speed, something we rarely try on most boats for safety reasons. Back at the dock, we asked him to characterize the boat’s handling with the Sharrow MX-1 compared to the two conventional props and he said, “A vast improvement.”

“We were able to make hard port and starboard turns at speed without the hull sliding or fear of overturning the boat, Captain Steve said. “The boat seemed ‘glued’ to the water.” That is because of the tremendous traction the Sharrow Propeller™ gets with what amounts to six blades grabbing the water.

Backing the boat into a slip was also much easier than with a conventional 3-blade propeller because of the added hold on the water and reduced slip.

Sharrow Propeller™ Model MX-1 Test Results

Comparisons

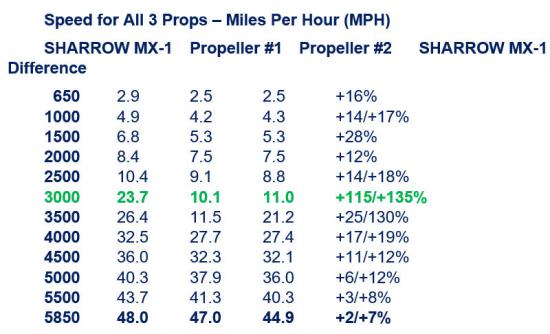

Speed. When we compared the Sharrow Propeller™ to the readings we got for the other two props, we found it was 16% faster than both at the idle RPM of 650. And, the miles per gallon difference was again 16% better for the MX-1. Range increased by 14.8%.

Because this is where 40% of the engine hours are employed, on average, according to ICOMIA, this data point is particularly important.

At 1000 RPM, we again compared the numbers we got for the Sharrow MX-1 propeller with the other two. It was 14% to 17% faster than the other two conventional props at the same RPM and gets from 4% to 8% more miles per gallon.

3000 RPM – First to Plane. The Sharrow Propeller™ got on plane at 2700 RPM. At 3000 RPM, we were going 23.7 mph and the running angle was 2.3-degrees, solidly on plane. This clearly outperformed both of the conventional three-bladed stainless-steel props.

The Sharrow MX-1 propeller doubles the speed, miles per gallon, and range of the other two props, while they are trying to get over the hump and on plane, even though the propeller pitch was only 15”, which is standard on this boat with a 150 outboard.

At 3500 RPM, we see that propeller #2 got on plane while propeller #1 was still struggling along pushing its bow wave.

At 4000 RPM, when the boat was solidly on plane with all three props, the aluminum prop was 17% to 19% faster than the conventional ss props.

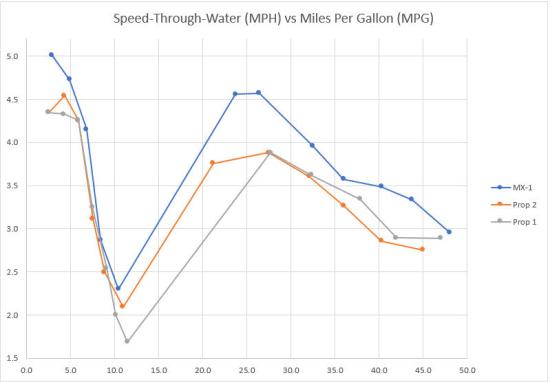

Fuel Efficiency Planing. When we compare fuel efficiency for the whole RPM range, we find the at idle, the MX-1 was 16% more efficient at idle and 15% more efficient at 5500 RPM. But the biggest difference was at planing speeds where the Sharrow MX-1 was as much as 179% more fuel-efficient.

Top to Bottom Speed Performance. Props can be designed to outperform the average in one, and sometimes two parameters. For example, boaters that want the highest top speed possible, and buy a propeller built for that purpose, typically find it will be less efficient at low and mid-range RPM settings. However, the Sharrow MX-1 outperformed two benchmark props across the board. This is a remarkable result.

At the end of the day, the numbers speak for themselves… and the most important number on this chart is the one at 3000 RPM when the Sharrow MX-1 was solidly on plane going 23.7 mph while the boat with the other props was still struggling to get on plane.

Fuel Economy for a Given Speed-Through-Water. The data table below is, again, remarkable because it shows that the Sharrow Propeller™ Model MX-1 is not only faster at all RPM, but also more fuel-efficient at all speeds.

For a few RPM settings, it appears the MX-1 is not the clear mpg at three RPM settings – but that is because it is driving the boat a lot faster at those RPM settings.

Graph 1

Sound and Vibration

Our sound readings in decibels are on the charts above. Engine noise is a combination of things, including sound emanating from the engine combustion itself, and sound coming from the harmonics of the boat caused by vibration transmitted to the transom.

As can be seen, the MX-1 prop was quieter than the Prop #1 at all RPM settings except two, where it tied. Compared to Prop #2, it was higher at one RPM, tied at three, and lower in decibels at all of the rest. So, overall, the test boat and engine were generally quieter with the MX-1 than with the conventional 3-blade props.

But there is more to the story. Without prompting, both of our test captains said the boat was noticeably quieter with the Sharrow MX-1 than the other two, and that difference is not adequately characterized by the decibel numbers – which are not linear. We suspect that there may be a frequency sound issue here, but we really don’t know at this point. In any case, the boat seems to be noticeably quieter to the human ear with the MX-1.

Vibration has already been touched upon. While we did not measure it scientifically, it was noticeably less with the MX-1 as reported by our test captains. Since 3-blade props typically have more vibration than 4-blade props, it is not surprising that the MX-1 has less vibration, because it really has 6-blades.

Testing Summary

Not Apples-to-Apples. Our testing of the aluminum alloy Sharrow MX-1 compared to two other stainless steel props of similar geometry was, in all likelihood, not fair to the MX-1 because typically stainless steel props far outshine aluminum ones in terms of performance. Greg Sharrow used aluminum alloy as a material for his prototype propellers because the relatively soft aluminum is easier and less costly to mill than stainless steel.

And, as noted, prop #1 had ¼” less diameter. Otherwise, our testing was as fair as we could make it for all three props.

After our testing and driving the boat with all three props, our conclusion is the following. The Sharrow Propeller™ —

- Performs significantly better at idle

- Plans at a lower RPM

- Is faster at all RPM settings

- Gets significantly more mpg at 3000 and 3500 RPM

- Is more fuel efficiency at every speed-through-water setting

- Is as much as 18% more fuel-efficient at 26-28 MPH

- Produces the highest top speed

- Creates noticeably less vibration

- Is generally quieter

- Has superior handling in tight turns at high-speed

- Improves handling in reverse

- Provides the greatest range at all speeds

Next Stop, Recreational Boating

Early-Adopter Registration Form

The Sharrow Propeller™ will make its exciting debut to the recreational boating community at the International Miami Boat Show in 2020. A select variety of pitches and diameters will be sold initially based on the highest demand from the “Join the Propulsion Revolution” form on their website, which can be found here: Click Here

Observations

According to Sharrow, thousands and thousands of people have already filled out the early adopter “Join the Propulsion Revolution” form on their website. Additionally, several boat builders and engine manufacturers have expressed interest in OEM versions as well. The naysayers will undoubtedly hit the boating forums almost immediately, so let us just say when we first heard about the prop, we were highly dubious.

But our testing and our investigation into the prop’s development has convinced us that there is a new prop design that not only excelled in our tests but may well make many non-loop propellers obsolete. That means millions of dollars in tooling owned by the engine and prop makers of the world might have to be written off as a loss on their books.

If that becomes true, we count on push-back from certain quadrants of the industry, rather than a more reflective wait-and-see posture. More tests, on more different types of boats, and with different prop sizes will likely be needed to sway the mossbacks. Progress is usually painful for someone.