14 New ABYC Standards for Boats

Standards are the core of ABYC as they are continuously researched, developed, and revised by over 400 volunteer marine professionals on 16 Project Technical Committees (PTCs) from all fields of the industry including the US Coast Guard (USCG), trade organizations, and private entities. ABYC collaborates with safety organizations worldwide such as Transport Canada and the International Organization for Standardization (ISO).

Consumer Caveat

The ABYC standards are strictly voluntary, and are not required by federal law. The National Marine Manufacturers Association has a certification program whereby it sends inspectors to check new models to verify if the boats comply with the standards on the boats provided for review. Each individual boat built is not inspected by NMMA or any other authority. Compliance is strictly the responsibility of the boat builder.

Boats built outside the U.S. may or may not follow the standards. Look for the “ABYC Certified” statement on the builder’s website on the boat. Boats built and sold in Europe are required to meet CE standards which are roughly the same as ABYC standards. Again, each individual boat is not inspected, and compliance with CE standards is up to the boat builder.

Today, 90% of boats on the water are said to be built to ABYC Standards. Over 3,000 technicians are trained and certified by ABYC to help builders, dealers and service techs, according to the organization.

Highlights of Updated Standards

Safety & Detection Systems

- A-14: Gasoline & Propane Gas Detection Systems

- A-24: Carbon Monoxide Detectors and Alarms

- A-31: Battery Chargers and Inverters

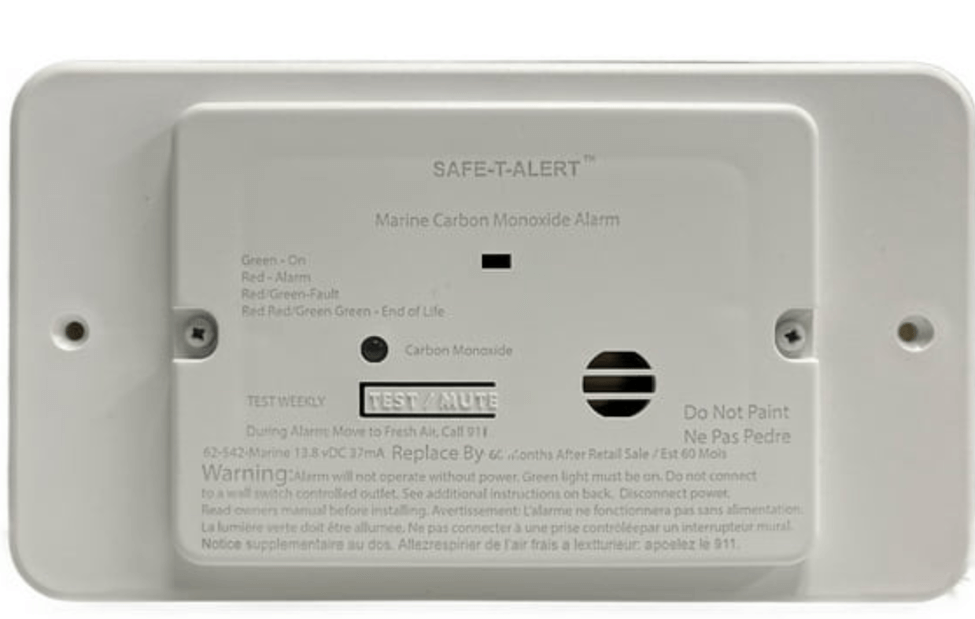

The ABYC Standard A-24 requires a marine-grade carbon monoxide (CO) detector on all boats with an enclosed accommodation compartment. Gasoline engines, generators, and cooking appliances are common sources of CO, a deadly, colorless, and odorless gas. Detectors must be located to monitor sleeping areas and main cabins, have a clear manufacturer's end-of-life date, and be replaced accordingly, as their effectiveness diminishes over time.

What the ABYC Standard Requires

Mandatory Installation:

ABYC A-24 requires CO detectors on all boats that have an "enclosed accommodation compartment", defined as a single, contiguous space that contains a designated sleeping area, a galley with a sink, and a head (toilet) compartment.

Marine-Grade Detectors:

Only detectors specifically designed and built for the marine environment should be used, as they are calibrated to different standards than household detectors. Detectors must have a clearly visible "replace by" date or end-of-life alarm. They should be installed to monitor the atmosphere in the main cabin and sleeping areas.

The detectors must be inspected and tested regularly according to the manufacturer's recommendations to ensure they are functional.

Electrical & Power Management

- E-2: Cathodic Protection

- E-11: AC & DC Electrical Systems

- E-13: Lithium-Ion Batteries

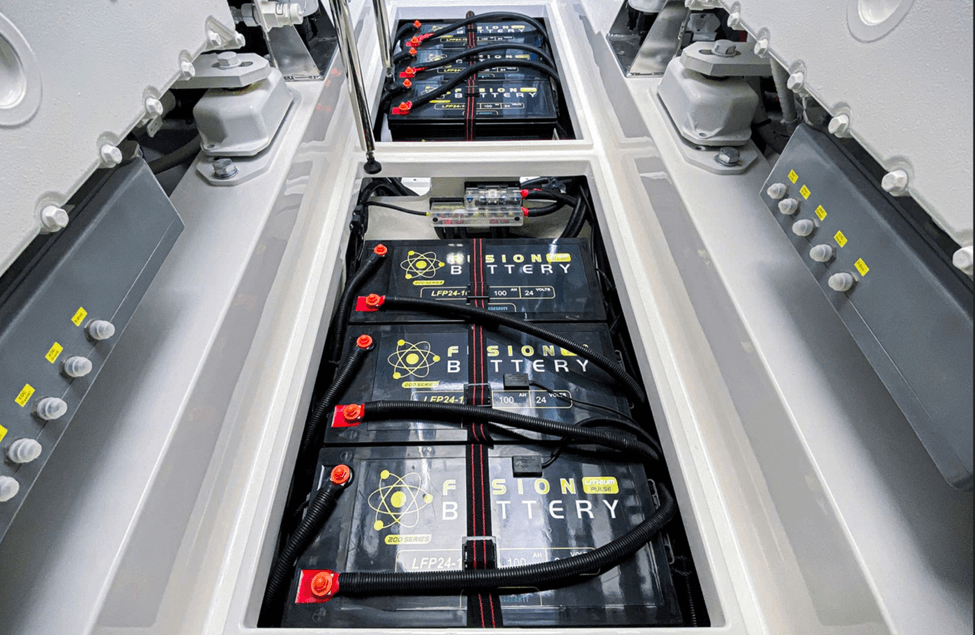

The ABYC E-13 standard, which became effective in July 2023, specifically addresses the safe installation and integration of lithium-ion (Li-ion) batteries on boats. Key provisions include:

The E-13 standard is a dedicated set of rules for the safe installation and management of lithium batteries on boats with a capacity of 600 watt-hours or more (50 amp-hours for 12V systems).

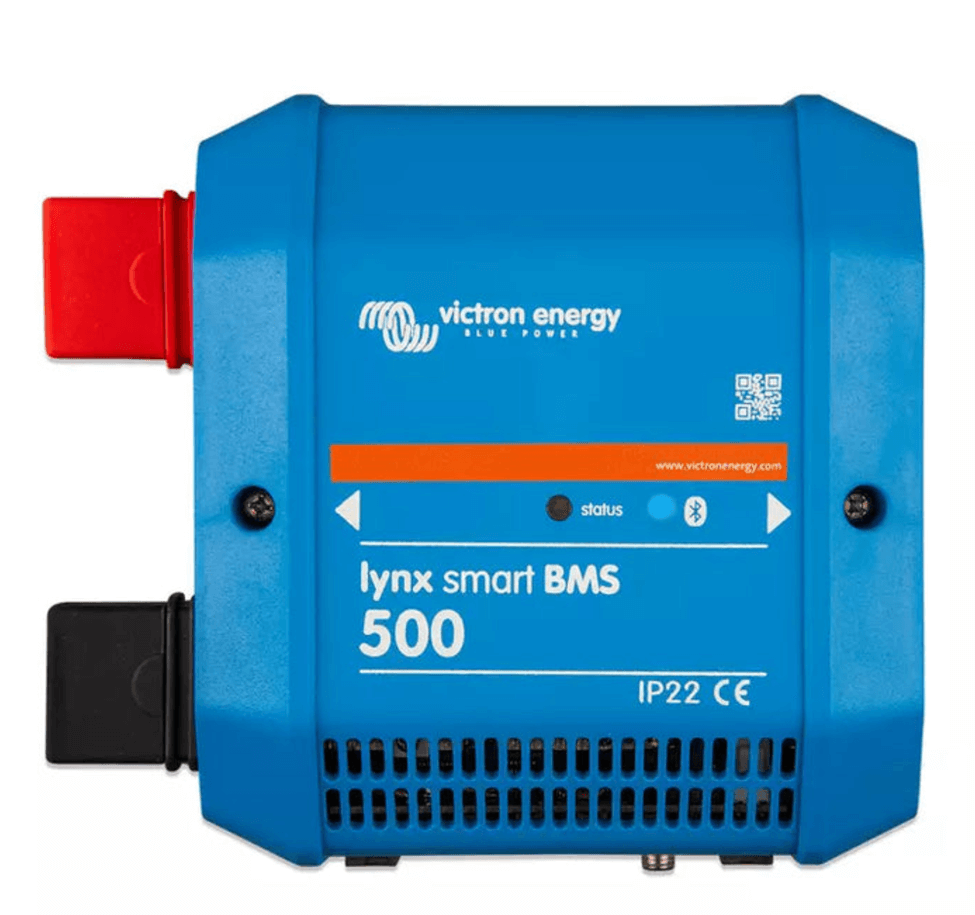

Battery management system (BMS) requirements:

- Mandatory BMS: A BMS is required for all marine lithium-ion battery installations.

- Protection features: The BMS must protect against overcharging, over-discharging, and over-temperature events.

- Alerts and disconnects: It must provide an audible or visual warning before a system shutdown and must be capable of immediately disconnecting the battery output if needed.

- Manufacturer data: The battery manufacturer must provide installers with detailed information on the BMS parameters.

- Preventing bypasses: No electrical connections are permitted to bypass the BMS.

Installation and equipment requirements:

- Secure mounting: Batteries must be securely mounted to withstand the marine environment without shifting.

- Ventilation: Proper ventilation is required to dissipate heat generated during charging and discharging.

- Overcurrent protection: Each battery output must have overcurrent protection, typically a Class T fuse, to prevent excessive current flow. For large banks over 500 amp-hours, fuses are required for each individual battery.

- Manufacturer instructions: Installation must be completed according to the manufacturer's specific guidelines.

- Product certification: Lithium batteries must have third-party testing certifications, such as SAE, IEC, or UL.

- Emergency power: An alternate power source is recommended for critical electronics to ensure operation if the main lithium bank is shut down by its BMS.

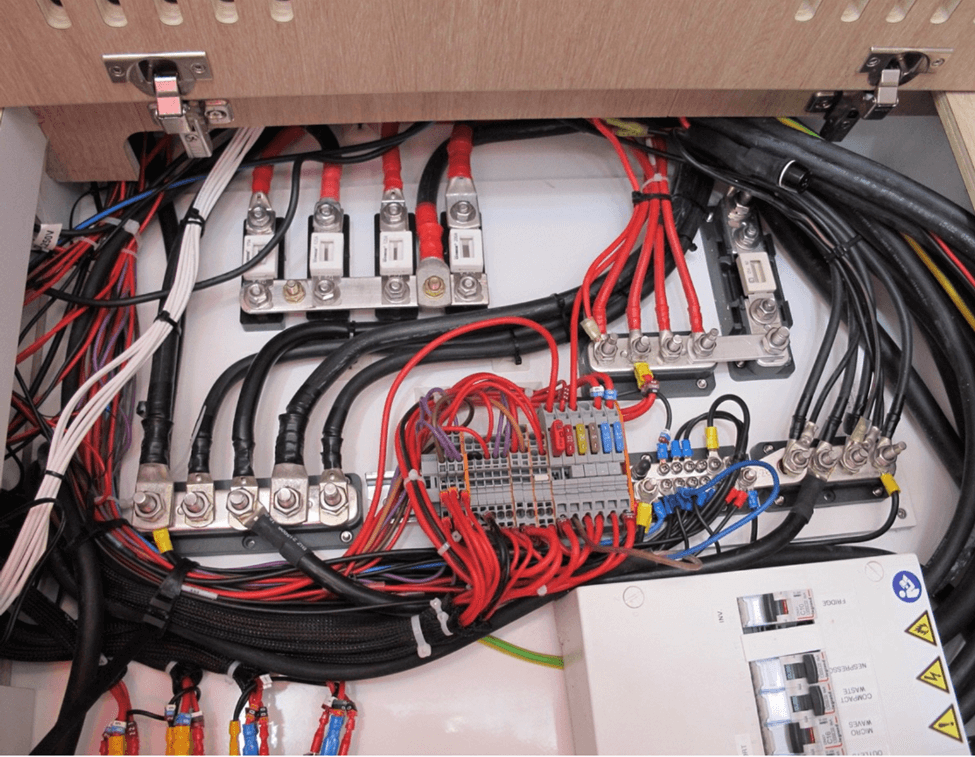

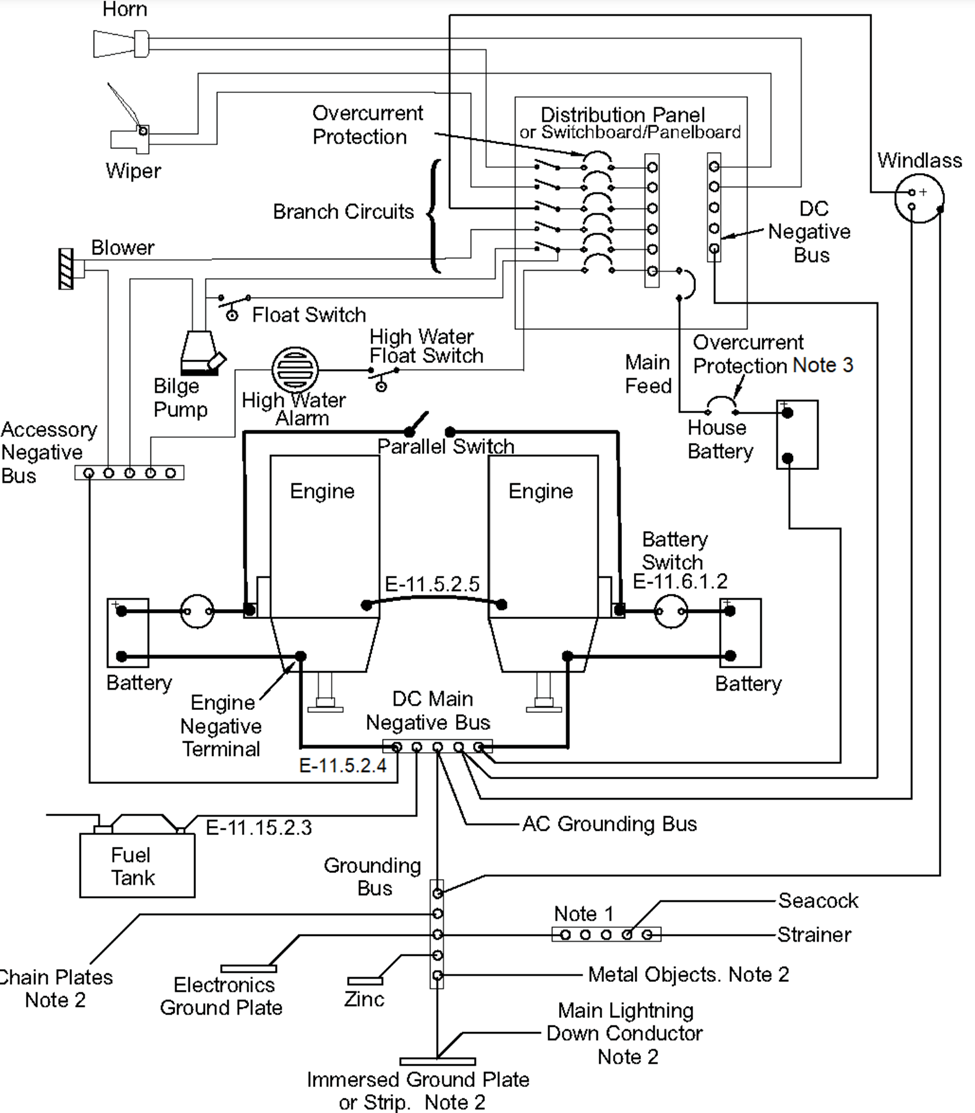

ABYC E-11: Power circuitry updates

Revisions to the E-11 standard cover both AC and DC electrical systems, with new requirements for advanced circuit protection and solid-state technology.

- Improved overcurrent protection: New formulas define the required amp interrupt capacity (AIC) for overcurrent protection (OCP) devices, scaling the requirement based on battery size and chemistry.

- Solid-state OCP: For the first time, solid-state overcurrent protection devices are permitted for use in branch circuits, though not as primary protection.

- Unchanging settings: The settings on resettable solid-state OCP devices must be clearly identified and not capable of accidental alteration.

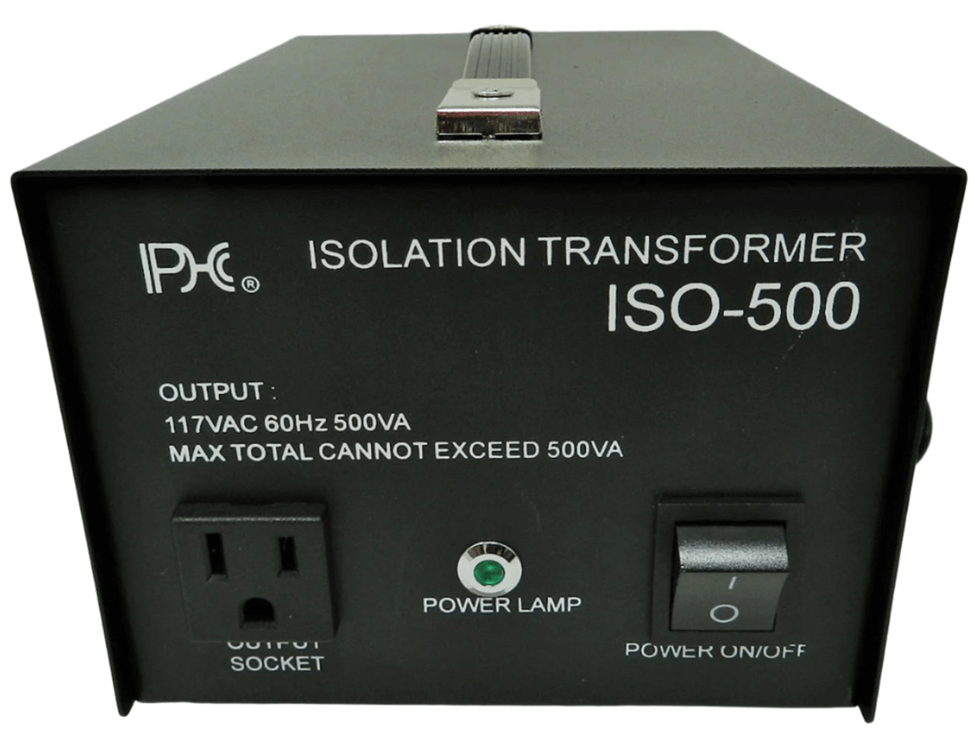

- Isolation transformers and ELCIs: The rule for installing equipment leakage circuit interrupters (ELCI) was clarified regarding situations where an isolation transformer is used.

ABYC E-2: Corrosion protection enhancements

The E-2 standard for cathodic protection received updates to ensure more effective corrosion prevention.

- Expanded anode requirements: The standard now includes more comprehensive requirements for sacrificial anodes, with expanded guidelines for both zinc and magnesium anodes.

- Improved bonding: Requirements for cathodic bonding conductors were revised to improve connection integrity and reduce resistance.

- Clarity on impressed current systems: The rules for impressed current cathodic protection systems were clarified to improve installation and performance.

- Hull potential measurements: Use of a reference electrode to measure hull potential is emphasized as a way to verify the integrity of the cathodic bonding system.

- Battery management system (BMS): All Li-ion batteries must have a BMS to protect against hazardous conditions like overcharging and over-discharging. The BMS must be able to automatically cut off the battery if safety limits are exceeded.

- Warning system: The battery system must provide an audible or visual alarm to warn the operator before a BMS-induced shutdown occurs. This gives the user time to switch to an alternative power source for critical systems.

- Installation requirements:

o Secure mounting: Batteries must be securely restrained to prevent movement and withstand the harsh marine environment.

o Ventilation: Adequate ventilation is required to manage heat during charging and discharging and to prevent thermal runaway. - Overcurrent protection: The standard mandates proper overcurrent protection through fusing to safeguard the electrical system from excessive current flow.

- Required documentation: Manufacturers must provide comprehensive safety information, including proper installation instructions, operating parameters, and details on how the BMS will perform a shutdown.

- Certified batteries: Li-ion batteries must carry certifications such as those from SAE, IEC, or UL to ensure they meet minimum safety standards.

Power circuitry standards

Recent updates to the E-13 standard on AC and DC Electrical Systems on Boats address new technologies and enhance safety, specifically regarding circuit protection.

- Solid-state overcurrent protection (OCP): The E-13 standard permits the use of solid-state OCP devices, though currently only for branch circuits, not as primary protection. These devices must be manually resettable and have safeguards to prevent settings from being accidentally changed.

- Interrupting capacity (AIC): New tables have been introduced that clearly define the required AIC for overcurrent protection devices based on battery chemistry and bank size. This provides more specific guidance than previous standards, which used a more universal 20,000 AIC rating for larger banks.

- Individual battery protection for large banks: For battery banks larger than 500 amp-hours, a properly sized fuse must be installed in-line before each individual battery joins the rest of the bank.

Corrosion protection standards (E-2)

The E-2 Cathodic Protection standard has also been revised to provide more specific guidance on protecting boats from corrosion.

- Expanded material guidelines: The latest revision expands requirements for different anode materials, including magnesium, which is increasingly popular for its performance in freshwater applications.

- Cathodic bonding conductor requirements: The standard now specifies revised requirements for bonding conductors, including material, size, and installation to ensure proper electrical connection and corrosion protection.

- Clearer system requirements: Clarifications have been made for impressed current systems, and a clearer expansion of measurement units and definitions has been included to improve clarity for technicians.

Drainage, Pumps & Water Systems

- H-4: Cockpit Drainage Systems

- H-22: Electric Bilge Pump Systems

- H-23: Water Systems for Use on Boats

Ensure reliable management of water on board under varied conditions.

Updates to the H-4 standard focus on ensuring that cockpit drainage is effective under various conditions to prevent the accumulation of water in a boat's interior. This is particularly critical for open boats or those with self-draining cockpits.

- Drainage requirements: Specific guidelines were revised to ensure that water drains efficiently and quickly. This prevents the "swamping" effect, where water remains in the cockpit, which can compromise stability.

- Preventing backflow: Changes emphasize the need for adequate drain size and proper installation to minimize the risk of water back-flowing into the cockpit, especially when the boat is underway or at rest.

H-22: Electric Bilge Pump Systems

The H-22 standard, which covers electric bilge pumps, received revisions to improve the safety and reliability of these crucial systems.

- Enhanced overcurrent protection: Bilge pump circuits must now have enhanced overcurrent protection (OCP) to guard against both running overload and locked-rotor conditions, which can cause a fire hazard.

- Continuous operation under stress: Pumps must be capable of operating continuously for 24 hours under the specified voltage without failing. They must also be able to run dry for a minimum of seven hours without becoming a fire hazard or have an automatic shut-off to prevent overheating.

- Improved electrical connections: A length of water-resistant electrical cable is now recommended, sealed at the pump connection, so that all electrical connections can be made above the maximum bilge water level.

- Better component durability: Updates require all materials to be corrosion-resistant and galvanically compatible to improve the longevity and reliability of the system.

H-23: Water Systems for Use on Boats

Revisions to the H-23 standard address both potable (fresh) water and non-potable water systems to ensure water quality and prevent contamination.

- Clarification of water system types: The standard now provides clearer guidance on the different types of water systems, including potable, gray water, and deck wash, and the requirements for each.

- Improved component testing: Requirements for system components like pumps, piping, and connections have been updated. Components for potable water systems, for example, must be non-toxic and tested to prevent contamination.

- Updated installation practices: Clearer instructions are provided for installation to prevent the siphoning of non-potable water into potable water systems, a key safety concern.

- Enhanced corrosion resistance: All materials used in these systems are required to be corrosion-resistant and non-reactive with the water being transported.

Fuel & Seat Structure Safety

- H-24: Gasoline Fuel Systems — now includes requirements for in-tank fuel pumps and hoses; USCG policy now deems compliance equivalent to federal regs, allowing more flexible tank-mounted pump placement without exemption.

- H-31: Seat Structures

These updates enhance safety and reduce regulatory friction (via USCG acceptance) for fuel systems.

Engine, Propulsion & Controls

- P-1: Exhaust System Installation

- P-14: Mechanical Propulsion Control Systems

- P-28: Electric/Electronic Control Systems for Propulsion & Steering

Focusing on secure, responsive control systems and safe engine exhaust design.

Updated Technical Information Reports

- TE-4: Lightning Protection

- TH-29: Sewage Systems

- TY-28: Boat Lifting & Storage

These offer non-mandatory guidance that complements the safety standards.

Why These Updates Matter

For Boat Builders:

- Essential for Regulatory Alignment

Updated ABYC standards are the baseline for safety. Builders can also rely on USCG policies—such as for H-24 in-tank fuel pumps—to innovate without seeking special approvals. - Streamlined Compliance Tools

ABYC’s Overview, Audit Tool, and Test Templates make integration of new standards into manufacturing, inspection, and QA processes smoother. - Advance Planning for 2027 Model Year

The recommended compliance timeline gives builders time to adapt their designs and documentation prior to enforcement. - Enhanced Safety Messaging

Demonstrating adherence to lithium-ion safety, updated seating, drainage systems, and CO mitigation helps build consumer confidence and offers better liability protection.

For Boat Buyers:

- Better Built-in Safety Features

Expect new boats to offer improved CO monitoring, safer drainage, upgraded fuel systems, and advanced battery solutions. - Improved Longevity and Reliability

Updates in electrical standards, corrosion protection, and systems like bilge and water management mean longer-lasting components. - Value in Resale & Surveying

Boats built to newer standards are easier to insure and tend to be more compliant in inspections, increasing resale desirability. - Access to Resources

ABYC standards—including A-24 on CO safety—are publicly available or accessible to members, and the Sept. 17 webinar is free for industry professionals.

Consumer Caveat: Compliance is solely the responsibility of the boat builder. That is why consumers must seek out builders with the highest reputation for build quality.

The ABYC (American Boat & Yacht Council) was founded in 1954 by members of the U.S. Coast Guard's Motorboat and Yacht Advisory Panel to develop voluntary safety standards for recreational boat design, construction, and maintenance in response to a booming post-war boating industry and a lack of safety guidelines. By establishing these standards through industry self-regulation, the organization aimed to preempt government regulation and has since become the primary global source for marine technical information, with its standards widely adopted and respected by the industry and cited by government bodies like the U.S.C.G.

To register for the 2025-26 Standards Update Webinar, visit www.abycinc.org/supplement65update.