AC Shore Cord Inspections: Don’t Overload Shore Power

With the increased demand to have all the electrically powered comforts of home onboard, it should come as no surprise to boaters that most of the AC electrical fires they’re likely to experience will involve overheated shore-power cords, plugs, and receptacles. As onboard power demands increase, so does the need to ensure that an AC power system is functioning properly. Let’s take a look at ways to make sure an AC shore power system remains safe and reliable.

The Problem

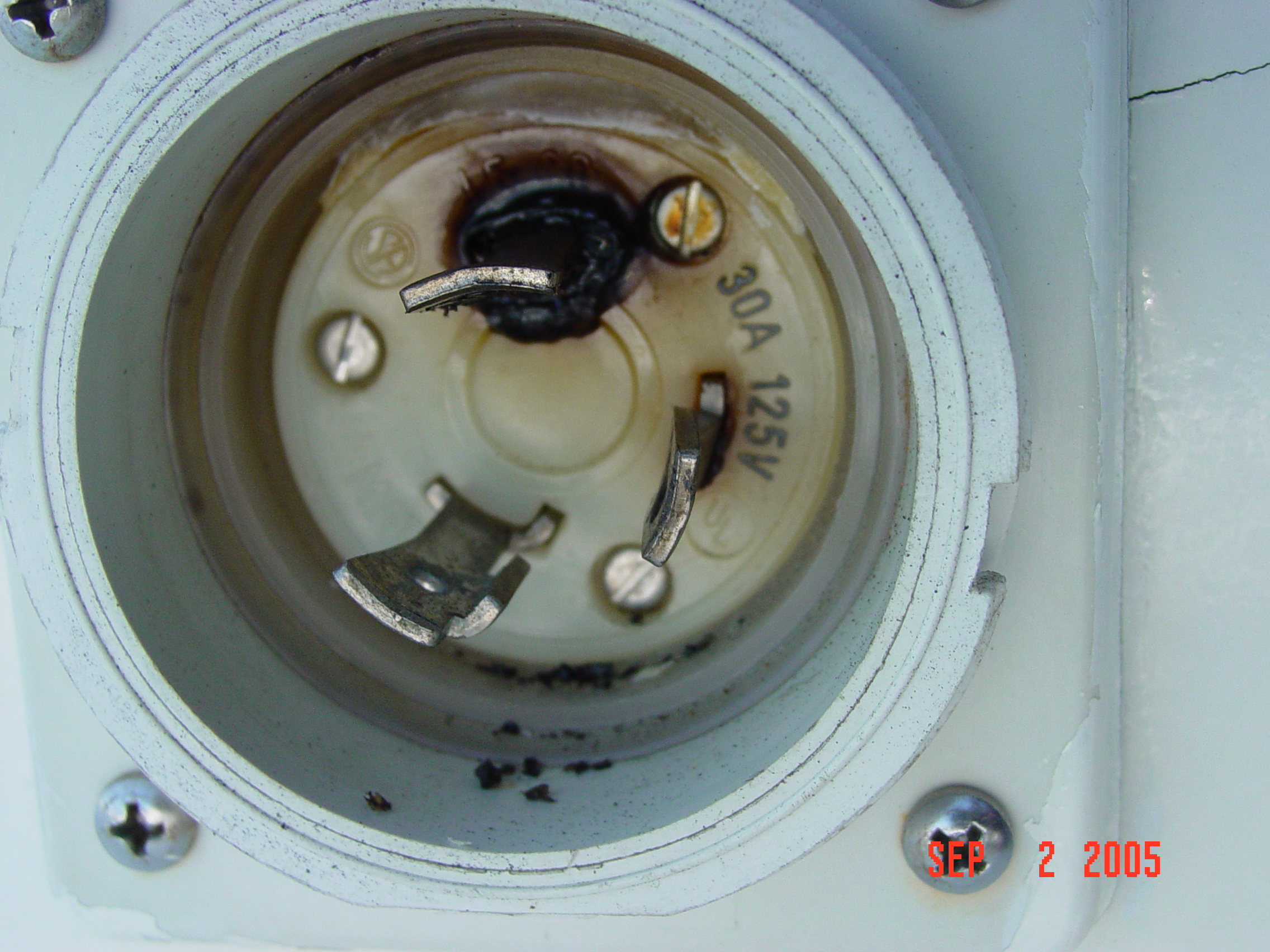

Barring improper use or some owner MacGyverism gone bad (jury-rigged adaptors, botched plug installations, etc) overheating and corrosion are the primary causes of shore-power system problems. Charred plugs and receptacles are the result of resistance buildup (due to loose or corroded connections). This generates heat and the potential for fire, a problem especially prevalent among vessels that continually run high-energy loads such as water heaters and air conditioning units.

In addition to plug melting and the like, excessive resistance has a more insidious side — unwanted voltage drops (which results in a decrease in available power) can cause electric motors to run slower (if at all), lights to burn dimmer, and excessive current draw.

Basic inspections of your AC shore-power system are easily accomplished and well within the ability of any boater. Knowing how to conduct them won’t make you a marine electrician by any stretch, however, it will hopefully help you spot and address potential problems before they worsen.

Two excellent references for those wanting to dig a little deeper are the National Fire Prevention Association (NFPA) Standard 303 “Fire Protection Standard for Marinas and Boatyards” and the American Boat And Yacht Council’s (ABYC) Standard E-11. Between the two, there’s information covering the entire AC system, from entry to the marina up to and including a vessel’s power inlet.

Inspections

The first step in inspecting the cord, plugs and receptacles of your AC shore power system is securing the power to avoid accidental shock hazards. Turn off your boat’s main AC breaker, the shore pedestal breaker, and unplug the shore power cord, and shut down generators and all DC to AC inverters you may have onboard.

Start an inspection with the shore power cord itself, ensuring it’s constructed of proper marine-grade components, uses appropriately sized wiring and is the shortest cord that will get the job done (use of undersized wiring or excessively long cords are also causes of excessive resistance).

Always replace cords that show signs of chafe, cracks, split insulation, or those having electrical tape repairs (which are expressly prohibited in NFPA 303). Homemade cords may look fine, but it’s generally impossible to verify that they meet standards for marine use — the same is also true for any cord not specifically labeled as such. The best course of action in such cases is replacement with one from a reputable marine manufacturer.

NFPA 303 also calls for shore cords to have molded-on plugs with sealing flanges or appropriate weatherproof boots. The plugs themselves should be checked each time you disconnect shore power (prior to getting underway for example) or monthly at a minimum, particularly for discoloration or corrosion on or around pins and plug inlets. By the time discoloration is visible at the front of a plug, you’ll typically find that the damage is greater upon opening up the back for inspection. If left uncorrected, the damage will snowball (due to increasing resistance and heat buildup) until it burns a hole through the face of the plug, possibly leading to a fire.

When inspecting a shore-power cord, it’s also crucial to include inspections of the dock pedestal outlet and a boat’s inlet receptacle, ensuring both are clean and undamaged. Many times owners will replace a damaged shore power cord or one of its plugs, only to later find it was damaged due to a burned dock receptacle or inlet.

Another good practice is checking the “feel” of the connection when plugging in. Those that feel loose or don’t seem to be making firm mechanical contact likely won’t provide good electrical contact either. Avoid using worn or damaged pedestal plugs and report them to marina personal as soon as possible.

Repairs

While repair of a faulty shore pedestal outlet is typically the responsibility of the marina, replacing a shore-cord plug, connector or boat inlet is within the ability of most boat owners, although it’s always a good idea to have your work inspected by a competent, preferably ABYC certified marine electrician. The important thing is to carefully follow all wiring diagrams and instructions. When replacing a plug or connector be sure to inspect the wire ends for charring or oxidation — if conductors are discolored or damaged, cut them back until you reach clean copper wire to make the connection.

A Pound of Prevention

In addition to regular inspections, keeping your plugs and connectors dry and corrosion free are the next best step towards heading off potential problems. If a connector or plug is accidentally dropped in the water secure power to the cord immediately, then give it a good rinse in fresh water. Allow the connector to dry thoroughly, then spray with a good marine grade contact cleaner / preservative to help prevent corrosion.

The same advice holds true for improperly stored shore power cords. Storing cords in cockpits or other open areas exposed to rain or spray can promote corrosion, as does a non-weather proof storage locker that allows power cords to rest in a pool of water. Ensure all shore power cords and adaptors are stored in a dry area or locker, well protected from both the elements and damage from other items stored there. Storage bags are available from most marine retailer and are an excellent investment, keeping all cords and adaptors readily accessible while protecting them from dirt and moisture.

Travel Smart

It’s also good practice to keep a can of electrical contact cleaner and a small brush (an old tooth bush works fine) in your tool kit for use in cleaning contacts at home dock and while traveling to different marinas. Securing the power cord at the dock power pedestal with a small length of line provides strain relief and helps prevent the plug from coming loose. You’ll also want to provide support to the rest of the cord so that it doesn’t hang in the water or generate undue strain at the boat’s receptacle (securely tightening the retaining ring where it plugs into the vessel will help considerably in this regard).

Finally, many of the household type electrical/electronic appliances boaters bring onboard (TVs, microwaves, etc) aren’t addressed by or designed with any marine standard in mind. To minimize the chances of failure, turn off individual appliances, all branch circuit breakers, then the main circuit breaker prior to turning off the shore side circuit breaker and unplugging the shore power cord (or during any shifts between generator and shore power).

By Capt. Frank Lanier

Captain Frank Lanier is a SAMS® Accredited Marine Surveyor with more than 40 years of experience in the marine and diving industry. He’s also an author, public speaker, and multiple award-winning journalist whose articles on seamanship, marine electronics, vessel maintenance and consumer reports appear regularly in numerous marine publications worldwide. He can be reached via his website at www.captfklanier.com.