Annual Maintenance and Regular Inspections of a Hydraulic Steering System

Every year about this time, boaters across the country start to get the itch. The days get a little longer and a little warmer and it just seems natural to grab the toolbox and the wash bucket and head for the boat.

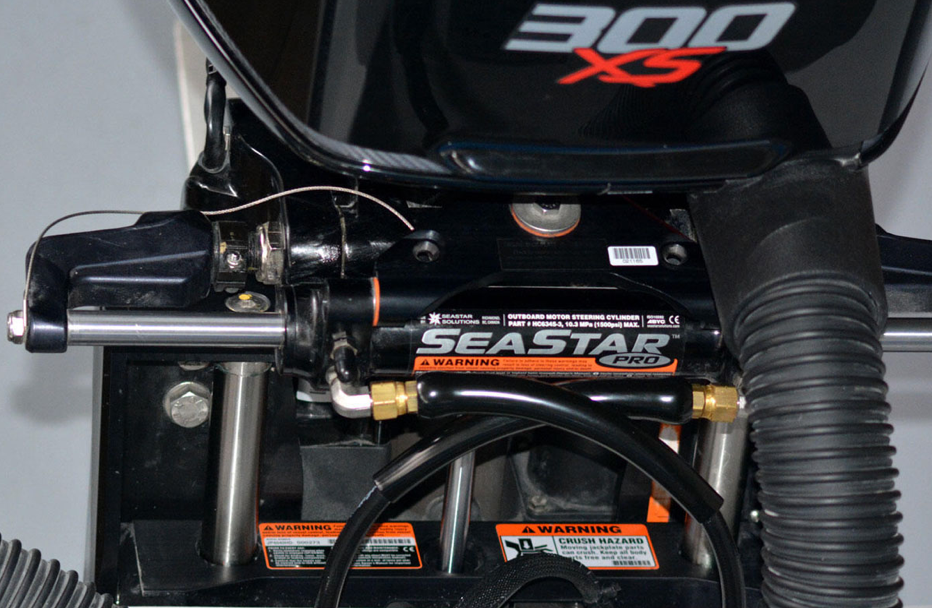

Most of us head for the transom to give the outboard or sterndrive a little attention. Now’s certainly a good time to change the engine oil, check the filters and take a look at the gear oil in the lower unit.

But few of us think to look a just a little bit forward and check out the hydraulic steering system. In fact, when asked, most boat owners said they had no idea there was anything they should do, or could do, to maintain their hydraulic systems. As a result, this vital control system receives little or no attention, and small problems resulting from normal wear and tear are left to become major headaches — and sometimes, costly repairs.

We' d like to encourage you to do a little preventative maintenance at least once a year, and to take the time to inspect your steering system every time you put your boat in the water. A few minutes looking things over will help you catch little problems before they become big ones.

Annual Preventative Maintenance

Every spring before putting your boat in the water, or more often if you put a lot of hours on your boat, you should perform a complete system check. You’ll need a wrench or two (the proper sized box-end or combination wrench is recommended over an adjustable wrench.) A torque wrench will also come in handy to make certain you tighten all fittings to spec. You’ll also need a good quality marine grease, like Sierra Premium Marine Bearing Grease, and an ample supply of rags or paper towels.

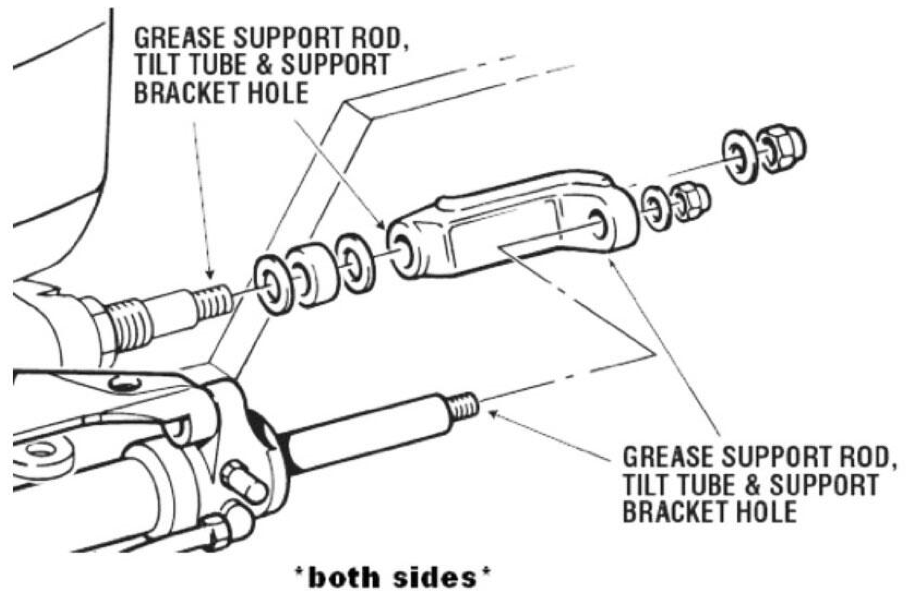

1. Back at the engine, remove the support rod from the steering/tilt tube. Clean out the steering/tilt tube. Really clean it out. Old grease can harden and needs to be removed, not to mention the fact that old, dirty grease will contaminate the new grease. Do yourself a favor and get rid of the old stuff before you re-grease.

2. Grease the support rod liberally and insert back into the tilt tube. Also grease the tilt tube itself, as well as the support bracket holes. Put a little grease on the threads before you insert the washers and tighten up the nuts. (DO NOT remove the tiller bolt to re-grease the cylinder).

3. Check the tightness of ALL fasteners and fittings throughout the steering system. Yes, this means getting under or behind the dash to check the back of the steering helm pump.

4. Remove the steering wheel and re-grease the wheel shaft.

5. Lastly, inspect the hydraulic oil for cleanliness. Flush the system with clean oil if it’s dirty. (This may be a task best handled by your dealer because it probably has an automatic pump that will refill and re-bleed your system.)

Do a Quick Inspection Before Every Trip

Level Check Check the fluid level in the highest helm pump. If the level is a little low, simply top it off with hydraulic fluid. (Take your time and keep a rag handy so you don’t make a mess.)

Turn Test Once you’ve checked the levels and replaced the cap in the helm pump, turn the wheel smartly from side to side. You’re looking for immediate response from the engine or drive unit. If there’s a noticeable lag in engine movement when you turn the wheel, you’ve got a problem somewhere in the system that needs to be corrected. Be sure you run this check on all the steering wheels on your boat, including the autopilot, if you’ve got one.

Hose Check Next, take a minute to look at all the hoses and fittings. You’re looking for wear, kinks and/or leaks. A hose might be rubbing against a bulkhead and creating a weak spot. Maybe a fitting has worked loose and there’s a little leak starting. Catching these problems early makes for easy fixes.

Ram Inspection Lastly, inspect the steering tube and support rod, take a look at the exposed ram shaft and make sure everything moves smoothly as the engine pivots from side to side. Take a close look at the seals and wipers, and check for any bends, nicks or damage to the steering ram shaft. (If you boat in saltwater, make sure you’ve installed a grounding strap to protect from galvanic corrosion.)

If you notice a leak, a kink, a catch or any other “hitch in your get along”, figure out what’s causing the problem and get it fixed before heading out for the day.

Steering is a vitally important control system on your boat. The ability to safely and confidently maneuver at speed or in close quarters makes for an enjoyable — and safe — day on the water. A little attention to your steering system before every trip and regular maintenance will assure you of proper operation — and long lasting performance.