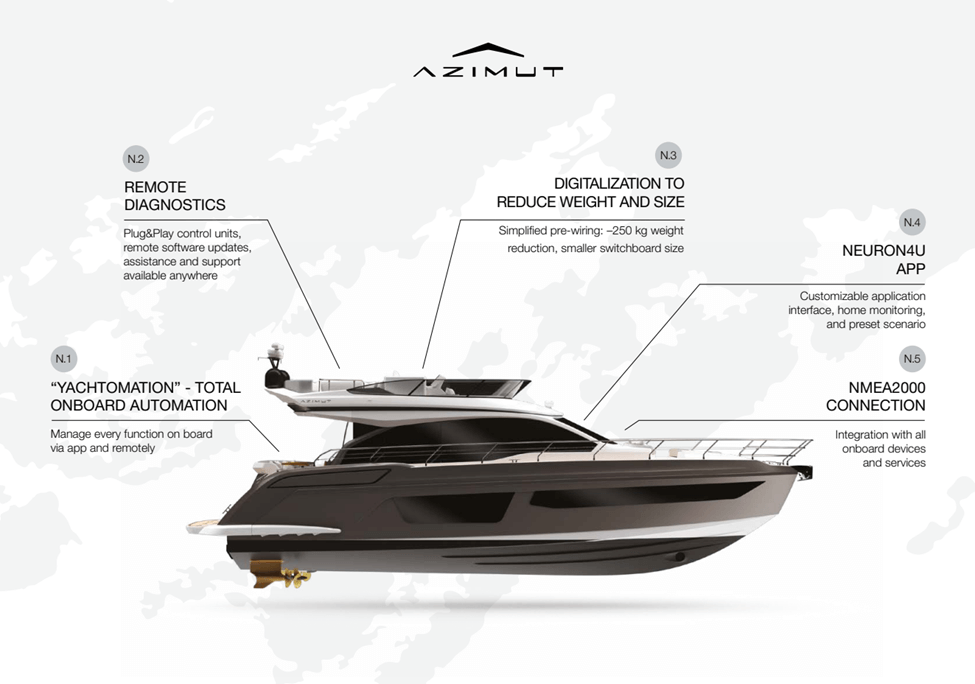

Azimut Introduces a “Neural” Digital Management System

Azimut recently announced a new system that combines digital software, machine learning, and telemetric connectivity to make operating a yacht easier and less costly for an owner. Called the “Neuron Digital Yacht Management System,” it contains all of the elements needed monitor a yacht’s complex systems from bilge pump to engine.

Every yacht owner knows that it is not a matter if a piece of equipment will fail, but when. And it always seems to fail when a big trip is planned. This new system will be simple to monitor and “ring a bell” when any of dozens of items of equipment get out of their designed spec and be an early-warning system for failure. Further, over time, it will be able to detect what systems or equipment needs to be improved for the Azimut fleet, if not yachts in general.

It can also have an important impact on “scheduled maintenance” with the possibility that a longer cycle might be possible between interventions because historical data indicates that it is not needed as often as thought originally. It provides owners with a customizable interface for managing onboard systems like lighting and climate control, offers remote troubleshooting capabilities, and aims to streamline maintenance, making yacht ownership more intuitive and efficient.

Key Features and Benefits:

Digital Integration: Neuron replaces traditional wiring with a digital system, reducing weight and space requirements. Going digital reduces wiring on a yacht by replacing the traditional "point-to-point" electrical system with a network-based one. In a digital system like Neuron, a single data cable can carry control signals for multiple devices, eliminating the need for individual wires running from a central panel to each switch and appliance.

| Traditional Point-to-Point | Digital | |

| Wiring | Each switch on a control panel needs a dedicated wire running to the component it controls (e.g., a specific light). For complex yachts, this results in a "multi-colored spaghetti" of heavy copper wires that are prone to corrosion. | A single, lightweight data cable, such as an NMEA 2000 backbone, connects various digital control modules. A module positioned near a specific zone, like the bow, then sends power to multiple local components (e.g., navigation lights). |

| Switches | Physical, mechanical switches are required at the helm and other control points. This leads to bulky control panels and numerous individual connection points. | The helm can be simplified with sleek touchscreens or smaller, programmable keypads that communicate with the rest of the system over the network. |

| Control | A switch can only control a single circuit, and it only works from the location where it is installed. | Digital controls allow for software-based functions. A single "night cruising" preset, for example, can dim instruments and turn on specific lights with a single command from anywhere on the network, including a remote device. |

| Efficiency | The long, winding runs of heavy copper wiring add significant weight to the vessel. | The drastic reduction in wiring, combined with the smaller size of digital components, leads to a significant reduction in overall system weight. |

Enhanced Automation and Customization

- Programmable presets: Owners can create custom "modes" that control multiple systems simultaneously with a single touch. For instance, a "Night Mode" could dim the interior lights, turn on navigation lights, and lower the volume of the entertainment system at once. A "Docking Mode" could activate specific lights and thrusters.

- Intuitive interface: Instead of a complex, cluttered panel with dozens of mechanical switches and circuit breakers, digital systems are controlled via a clean, customizable touchscreen interface. Icons and animations make system status easy to understand at a glance.

Improved Safety and Reliability

- Real-time monitoring and alerts: A digital system provides constant, real-time monitoring of all connected systems. If there is a fault, such as a bilge pump circuit drawing too much current, the system immediately sends a warning to the helm and the owner's app. This allows issues to be addressed before they become major problems, enhancing safety at sea.

- Vibration: Sensors detect unusual vibration patterns in rotating machinery, such as motors and pumps. This can indicate problems like bearing failures, misalignment, or imbalance.

- Temperature: Temperature fluctuations can signal friction issues, electrical problems, or general wear and tear. Infrared analysis can monitor component temperatures over time, with sudden spikes potentially indicating a developing issue.

- Electrical current: Monitoring the electrical current drawn by pumps and other components can identify anomalies. An increase in current, for example, could signal a blockage or a component starting to seize.

- Pressure and flow rates: Sensors monitor pressure in fluid systems like pumps, hydraulics, and water systems. Unpredictable pressure drops or fluctuations can indicate a leak, blockage, or pump failure.

- Acoustic emissions: Ultrasonic microphones detect high-frequency sounds that indicate potential issues like leaks in pressurized systems or electrical discharges.

- Solid-state protection: Digital circuit control modules eliminate vulnerable mechanical components like fuses and mechanical circuit breakers. This means fewer moving parts to fail and greater resilience to the marine environment, which can cause corrosion in traditional systems.

Remote Control and Monitoring

- Total remote access: Owners can monitor and control various yacht systems remotely via a connected smartphone or tablet. For example, you can check the security system, turn on the air conditioning, or run systems before arriving at the marina.

- Enhanced security: Remote monitoring of security systems provides peace of mind, allowing owners to check their vessel's status from anywhere.

Simplified Maintenance and Repair

- Historical Maintenance Data: To inform its machine learning models, Neuron aggregates and analyzes historical information to identify patterns that precede failures.

- Past maintenance records: Data from previous repairs, including replaced parts and the condition of equipment during service, helps the algorithm learn about degradation patterns.

- Equipment metadata: Information about the specific components, such as manufacturer, model, and date of service, provides a baseline for understanding normal operational characteristics.

- Previous failure patterns: The system learns from past incidents and near-misses to better predict future failures.

How the data is used. The combination of these data types allows the system to build a comprehensive "health profile" for the yacht.

- Establishing baselines: The system first learns the normal operating parameters for the yacht's equipment under various conditions.

- Anomaly detection: It then detects any subtle deviations or anomalies from these normal patterns.

- Predicting failure: By comparing real-time anomalies with historical failure patterns, machine learning algorithms can predict the likelihood and timing of a future failure.

- Generating alerts: This triggers an alert for the owner or service technician, who can then proactively schedule maintenance to prevent an actual breakdown.

- Easier Repairs: The modular, plug-and-play architecture makes repairing or replacing a failed component much simpler and faster.

- Seamless Upgrades: Adding new equipment is as easy as installing a new digital module and configuring it on the network. This is far less costly and time-intensive than retrofitting a traditional analog system.

- Software Updates: The digital nature of the system allows for software updates to add new features or improve existing functionality without needing to replace any hardware.

Improved Energy Management

- Automated power consumption: The system can optimize power consumption by adjusting electrical loads based on real-time needs.

- Performance integration: Digital throttle and shift systems integrate with the rest of the electrical system to deliver more precise engine control, which can lead to smoother handling and improved fuel efficiency.

Development and Rollout

Neuron is the result of a collaboration between Azimut Technical Development and MDP Tech. It was developed following a successful trial on an Azimut Fly 53 and is slated to become standard on Azimut models up to 24 meters (80 feet). This system is a key component of Azimut's strategy to enhance the digital experience for its owners and improve operational efficiency.

Here are the key points regarding Neuron's availability:

- Standard equipment: Neuron will be included as a standard feature on all new Azimut models below 80 feet, meaning it will not be an optional extra.

- Target size: The system is specifically designed for smaller and mid-sized yachts within the Azimut fleet, which range from around 42 to 80 feet.

- Rollout timing: The rollout will occur gradually across the relevant production lines as part of Azimut's ongoing digital transformation initiatives, following a successful six-month trial on an Azimut Fly 53.