Best Waxes and Ceramic Coatings for Your Boat: Ceramics for the Ultimate Shine, Part 2

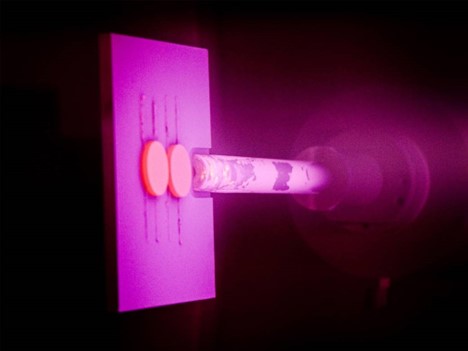

Ceramic coatings were first used by NASA in the early 2000’s for engine protection, with a 10,000 degree plasma flame injected with ceramic powder under a vacuum to coat internal parts for much increased lifespan.

Ceramic coatings you can buy in bottle obviously are not the same thing. However, ceramic coatings now marketed for marine and automotive finishes are definitely a step up from conventional waxes and polishes.

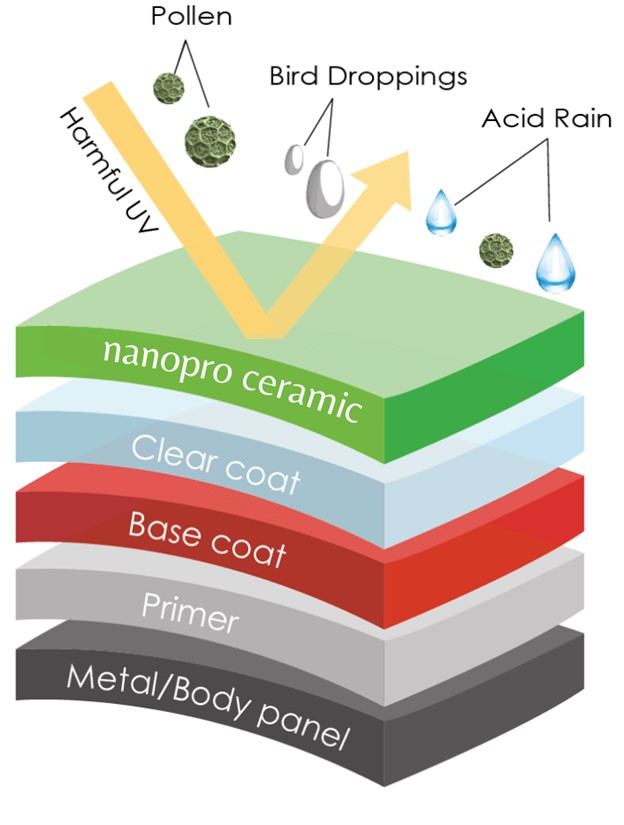

Commercial ceramic coatings are made up of microscopic particles of silicone in a liquid polymer binder. When the solvent dries, the silicone particles remain to protect the surface. The stuff dries hard (and very shiny) to a thickness of up to 5 microns (.0002”), in effect becoming another layer of clear-coat atop your gelcoat or paint. (The clear-coat on a painted boat or vehicle is typically 35 to 50 microns thick.)

Ceramic coatings can also be used on metal parts, helping to fight corrosion and keep them Bristol fashion.

The silicone layer is so slick that water spots are less likely to develop because most water slides right off, and it also prevents bird droppings and other corrosives from damaging the paint (or metal) underneath.

Ceramic polish applied below the waterline on boats without algaecide bottom paint is also said to reduce barnacle and algae growth by increasing surface tension and preventing marine life from planting roots into the pores of your gel coat—great for trailered boats that might be left in the water over the weekend but not for extended periods.

Ceramic coatings also provide a more lasting shine than conventional waxes, with some companies claiming lifespan in years instead of months.

However, they are more expensive, even if you do it yourself, and way more if you have it done due to all the required pre-cleaning and buffing. (Expect to pay about $65 a foot—around $2200 for a typical 35-footer.) If you DIY, it’s a must to be sure the ceramic is completely dry before any final wipe down—and the drying process can take days with some products.

A full package from GlideCoat is about $395 for self application.

https://www.glidecoat.com/case-study/how-to-choose-the-best-ceramic-coating-for-your-boat

The Ceramic Coating Process

Ceramics provide a remarkable finish—but only if the surface prep is done right before they’re applied.

First thing you have to do is remove every trace of the old wax or sealant; if you don’t, when it lifts—and it will—it’ll take the ceramic coating off with it.

Experts say the best bet is to use a dewaxing solution, rather than trying to buff it off—a dewaxer from a company specializing in ceramics is likely to be effective for wiping down the hull. (Dawn dishwashing detergent in water is also a favorite of many experienced boaters, fyi. It apparently has the right pH to cut most old waxes.)

Once the wax is off, you can take a look at the finish itself—if it’s hazy or has a lot of surface scratching, you’ll probably want to work the hull over with a fine rubbing compound to make things the best they can be—doing it by hand with a microfiber cloth gets it done, but a 7 to 10 inch buffer used at low speed and light pressure will do it much quicker.

The pro’s advise against buying “pro grade” ceramic for self-application thinking you’ll get a better finish. The pro stuff dries faster and so is harder to work with.

The pro coating fully cures in eight hours; the DIY ceramic requires 48 hours. The DIY product not only gives you more working time, it’s self-leveling so it’s less apt to streak. Its slower cure means errors can be polished out and recoated the next day.

Here’s a look at some of the companies that make good ceramic coatings directed to the marine market:

Ceramic Pro, as the name implies, is aimed at professional crews and yards and is not recommended for DIY users. The company says it’s good for below-the-waterline use on boats where the last fraction of speed is sought due to its low friction coefficient. The coating also brings out the grain of natural teak and improves its durability, and can also be used to brighten up vinyl seats. The product is only applied by yards that have been certified in the process, per the company; https://ceramicpro.com

Glidecoat makes packages designed for consumer application, including the Ceramic Top Coating Kit, listing at $295. The package makes it easy to understand the process of cleaning the hull, compounding it to get rid of scratches and fading, then polishing, then final wipedown, and then adding the ceramic coating. The 160 ml (5.4 oz.) kit is for boats to 20’ (6 m) —added kits for 30’ (9 m) and 40’ (12 m) boats are also available. The company claims the shine will last up to 18 months in most duty; www.glidecoat.com.

GTechniq Crystal Serum Light is a consumer version of the company’s professional ceramic coating. It’s pricey at $75 for 30 ml (1 oz.), but the company says a little goes a long way. Curing time is about 12 hours, and they recommend a follow-up with their C2 Liquid Crystal, a spray-on that adds a deeper shine and assures water runoff for about 6 months between applications—it’s $15 for 250 ml (8.5 oz.); https://gtechniq.com.

The Hydrosilex $90 kit includes wax remover, ceramic coating and a silica soap that the company says is easy on the finished surface. Scratch-free microfiber towels are also included to ease application. The surface prep is critical, the company says—their remover is a combination of isopropyl alcohol, degreaser and soap that goes on like water but cuts multiple layers of scum as well as old wax with a light rub. The company’s how-to videos are instructive for boaters, though they’re primarily aimed at the automotive market; www.hydrosilex.com.

Marine Maxx offers easy-to-apply ceramic coating in spray bottles that the company says is easier to apply than most, and also much less expensive at about $35 for a pint (473 ml) bottle. The product works for fiberglass, paint, vinyl seats, stainless steel hardware and glass and plexi windshields. Basically just spray on, spread with a microfiber towel and then wipe off with a second microfiber towel and you’re done, per the company—much faster than some ceramic products, and it lasts up to six months. https://marinemaxxceramiccoating.com

Permanon products are sold in concentrate, and the company says a 500 ml (17 oz.) bottle of concentrate will make 10 liters (340 oz.) of ready-to-use product at a 5% mix, which will cover a total of 3,229 square feet. However, for surfaces likely to get direct sun for extended periods, like decks, they recommend using the products full strength for maximum durability. A 1 L (34 oz.) bottle is about $153; www.permanonfinishes.com.

Sea-Shield makes a full line of ceramic coatings and restoration and cleaning products aimed primarily at yards and professional crews maintaining large yachts. Their full Advance Pro Pack including everything from cleaner to final coating, microfiber pads and sanding equipment, is $1485. The company website also includes a number of how-to videos on applying their products, useful for ardent DIY owners; https://sea-shield.com.