On Board Pump Systems: Go With the Flow

Boats contain several pumps, each serving a unique purpose and positioned in a way that allows it to do its job effectively. Understanding the why and the how can be important troubleshooting issues.

Some of these pumps are located where you can’t see them and some serve purposes we may not want to think too much about (moving waste or saving the boat from sinking.) Others are engine-specific — and can appear overwhelming, at first.

What they all have in common is pretty simple: Pumps move fluid from one spot to another. Let’s take a closer look:

The First Two are Engine-Specific:

Seawater Pump — This pump has an impeller (a rubber device with vanes that turn similar to a paddle wheel) that draws from the water surrounding the boat to the engine. The water is used to cool the engine down when it’s running. The water flows through the engine and is then spit out with the exhaust. The most common item of failure is the impeller. If water is not flowing to or through the engine, the impeller is a likely culprit.

Circulating pump — This pump forces water through the various engine passages as the engine temperature rises. Typically not designed to be serviced, if it fails, the entire unit is replaced.

The next group of pumps isn’t attached to the engine. Each serves individual applications:

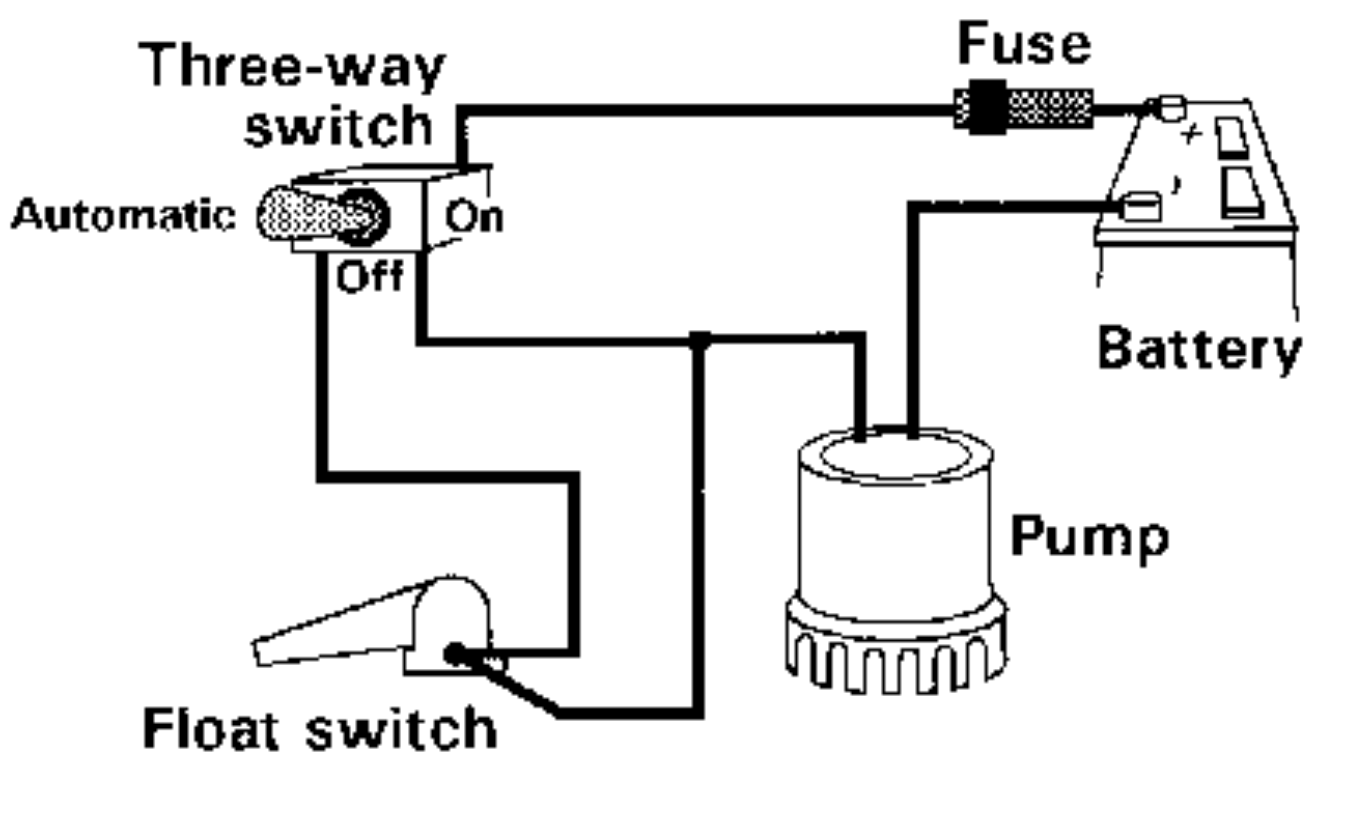

Electric Bilge Pump — This pump is designed to pump water out of the boat when it accumulates in the bilge (the lowest part of the vessel’s keel.) It is powered by electricity and commonly activated by a float switch; as the water level in the bilge rises, the float rises along with it. At a pre-determined height, the float engages the pump.

As the water leaves the bilge, the float lowers and the pump turns off. Often, these pumps can be operated with an on/off switch. Bilge pumps can become clogged with debris and the float can fail as the weakest point in the system. They should be cleaned and checked regularly.

Manual Bilge Pump — Serving the same purpose at an electric bilge pump, it is powered by a foot pedal or handle. Commonly found on sailboats, this pump is located in the cockpit, and may be used as an emergency pump. Because of the ease of electric pumps, manual pumps aren’t used often. Rubber gaskets and diaphragms leak or crack and render the pump inoperable. They should be checked at least annually.

Macerator Pump — These pumps move waste from the toilet/head to a waste tank in a “push to flush” system. They are located in the base of the toilet unit so access can be tough. Luckily, these pumps are relatively bulletproof unless one is overloaded or overfilled.

Manual Toilet Pumps — Operated by hand, the toilet waste is pumped from the bowl to the waste tank. The operating mechanism requires that the seals around the handle keep a tight seal. Failure is often attributed to a poor seal. In many cases, a toilet re-seal kit can be used to replace O-rings and one-way valves.

Shower Sump — This pump is located beneath the shower drain: when water flows down the drain, it enters a small box with a pump and float system. As water accumulates in the box, the float rises and the water is pumped overboard.

Freshwater Pump — These pumps move water from the tank through the freshwater system to the faucets and taps. They operate based on the pressure in the system: once the system is pressurized, the pump turns off on its own. The danger is that a cracked or broken line or dripping faucet will cause the pump to run continuously. The system should be checked regularly to ensure that it activates, pressurizes and shuts off appropriately.

Aerating/Livewell Pump — This is the opposite of a bilge pump: water is pumped from overboard into a livewell. Practical only on boats designed for fishing, this keeps fish and bait alive.

Ballast Pumps — Typically found only on larger vessels requiring moveable ballast for stability purposes. These pumps move water into ballast tanks from the surrounding body of water to adjust for movement while underway.

Washdown Pumps — Used for providing water to a handheld faucet at the bow or stern to “wash down” when re-boarding the boat. Closely related to a freshwater pump.

Air Conditioning Pump —This provides the water necessary to allow an air conditioning unit to run and cool appropriately. Typically self-contained units and can’t be serviced.

A Few Tips for Longevity

- Ensure that the right pump is installed for the right purpose. Bilge pumps, freshwater pumps, macerator pumps and shower sumps can look remarkably similar.

- Install filters in-line between the water source and the pump. This will help filter out dirt and debris

- Try not to run the pump dry. It is meant to move water and the fluid keeps the pump lubricated and cool.

- Winterize the pumps appropriately: flush pumps through the antifreeze to displace any water and protect it from freezing damage

- Check pumps periodically to ensure that they’re sealed and working correctly. In the event that there is a loss of pressure, check seals and diaphragms and have them serviced or replaced for best functionality.

Pumps are essential for enjoyment and ease of use on a modern boat. A bit of service goes a long way in keeping them running efficiently and hassle-free.