Coping w/Ethanol-Enhanced Gasoline

My Boston Whaler is powered by a 20-hp outboard and was disabled twice last summer thanks to a sticking needle valve in the engine’s fuel system. The engine would run flawlessly and then a week later wouldn’t run again. The most likely culprit was gum or varnish that was being dislodged by the solvent effects of the ethanol in the fuel.

As we uncover our boats out after the long winter, it’s worthwhile to revisit the ethanol issue because things seem to be getting worse, not better. We went to several of the top tech experts on this matter and we will share with you their best recommendations.

Better Understanding

Tetraethyl lead was long used as an octane booster in gasoline but has been banned due to environmental problems. To replace that lost octane boost, oxygenated fuels were introduced and they usually contain either ethyl alcohol (ethanol) or methyltertiary-butyl-ether (MTBE). MTBE, too, raised environmental concerns so now ethanol has become the commonplace solution.

Remember: Gasoline is formulated for a car or truck — not for marine use. A vehicle burns a tank of fuel in a short period of time and vehicles have long been equipped with closed fuel systems that minimize evaporation and deliver fuel under pressure to fuel injectors. Fuel dispersants like detergent are added to help keep fuel injector nozzles clean. Little air enters the system.

Your boat’s fuel system has the opposite. Marine fuel systems are vented to the air because fuel must be drawn into the engine under a vacuum. It’s a safety feature. Should a hose come loose or the fuel system develop a leak, gasoline stops running.

Two Problems

We can divide the ethanol fuel problems into two general areas: operating problems and fuel-system problems.

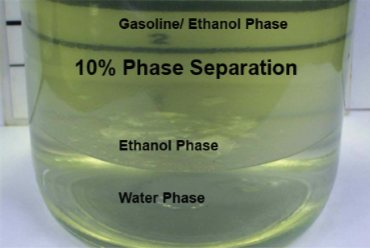

Operating problems come from gum, varnish and debris from fuel system hoses and parts that the ethanol has attacked. The most dramatic operating problem occurs when a blob of water and ethanol gets sucked into the carburetor, causing the engine to stop or stall. These blobs are a result of “phase separation.”

Because ethanol and water readily dissolve in each other, when ethanol is used as an additive in gasoline, water will dissolve in the blended fuel to a much greater extent than in conventional gasoline. When the water reaches the maximum amount that the gasoline blend can dissolve, additional water will separate from the gasoline.

The amount of water required (in percent of the total volume) for this phase separation to take place varies with temperature, but as an example, at 60 degrees F, water can be absorbed by a blend of 90% gasoline and 10% ethanol up to a content of 0.5 volume percent before it will phase separate. This means that approximately 3.8 teaspoons of water can be dissolved per gallon of the fuel before the water will begin to phase separate.

Owners of diesel-powered boats may think that ethanol doesn’t affect them. Think again if you have a tender with a small outboard. Those engines are often exposed to the ethanol issue because most dinghies are stored for long periods of time between uses. Things get worse again if that little engine is a key part of your safety gear. Water can enter ethanol-enhanced gasoline directly (rain water splashing into a fuel vent – think of a vented cap on a portable fuel tank) or through moisture being absorbed from the air due to condensation.

To get more than 3.8 teaspoons of water into the bottom gallon of fuel in an outboard’s portable tank might not take many cool fall nights. Water as a separate phase, can have a major effect on two-stroke outboards. When the ethanol bonds with the water and drops out of the gasoline, the effective octane rating is decreased. In the case of two-stroke engines, this water-ethanol phase will compete with the blended oil that bonds to metal engine parts. Therefore, the engine will not have enough lubrication and internal damage may result.

In the case of four-stroke gasoline engines, the water-ethanol phase may combust in the engine. This combustion can be damaging to the engine because the water-ethanol phase creates a leaner combustion mixture (i.e., air to fuel ratio is higher than ideal). Leaner mixtures tend to combust at higher temperatures and can damage engines, particularly those without sensors to calibrate air to fuel ratios.

Expert Recommendations

•Check with your marina or gasoline retailer. Some retailers are getting better around labeling pumps with “Contains No Ethanol” signs. If you can be sure your fuel has no ethanol, you have no problem.

•Ethanol is known to chemically react with many fiberglass fuel tanks. They can deteriorate and potentially fail causing serious engine damage and potential fuel leaks. Unless your boat's manufacturer can confirm that your fiberglass tank was built to withstand ethanol, replace the tank with a non-reactive material such as aluminum.

•Always use fuel stabilizer. For any stored gasoline, it's important to add a stabilizer. Also, several engine manufacturers now recommend adding a “maintenance” level of stabilizer in every tank. However, stabilizers do not prevent phase separation. Once it occurs, additives and water separators can't help. The only remedy is to have the gas and ethanol/water professionally removed from the tank.

•Before storage, run your boat for a time on stabilized fuel to best ensure that fresh, stable fuel is all that remains in the system over the winter.

•For boats with built-in fuel tanks, if possible, professionally drain and clean the tanks completely. We realize this is highly impractical though, so alternatively, add stabilizer and then almost fill the tank, leaving it with just a little room for expansion. A tank that is almost full limits the flow of air into and out of the vent, which reduces the chance of fluctuating temperatures adding condensation (water) to the fuel and thereby reducing chances of phase separation.

•If you have (or can change to) portable 5-gallon tanks, any unmixed gas (without 2-cycle oil) remaining may be carefully poured into your automobile gas tank and used. If you must store gas over the winter, keep the tank out of the sun and in a well-ventilated area away from ignition sources, keeping in mind that gasoline fumes are heavier than air.

•For all marine gasoline tanks, never try to plug up a fuel tank vent to prevent moist air from entering a tank. Without room to expand, the additional pressure could rupture fuel system components. Don’t block the vent with shrink wrap.