Corrosion, Part 2: Stray Current

In part one of this series, we focused on galvanic corrosion that occurs when dissimilar metals are immersed in an electrolyte like seawater. This corrosion happens naturally: metals corrode over time and changes can be noted from season to season.

Stray Current

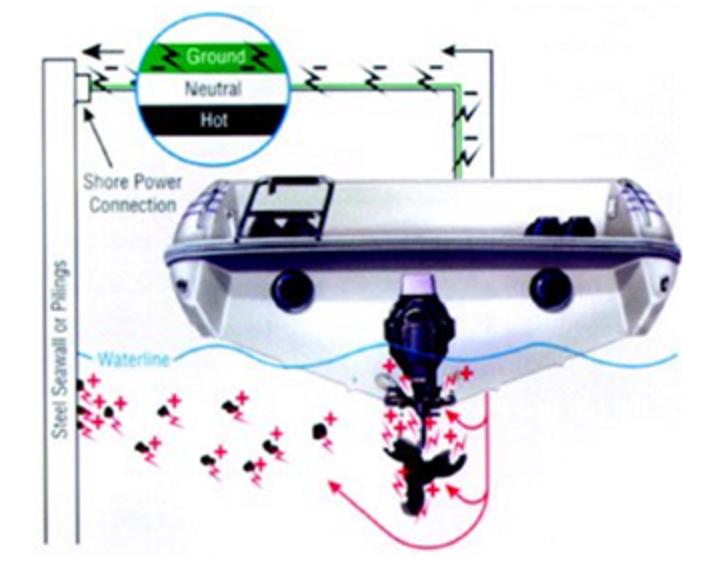

Stray-current corrosion differs significantly from galvanic corrosion because it occurs when a metal with an electrical current flowing through it is immersed in water that is grounded. As the current flows through the metal and seeks to find ground, electrons from the metal are taken with it, causing the metal to corrode.

Electricity, by its nature, always seeks a return path to its source. Most often, stray-current corrosion involves a faulty electrical connection that makes contact with a submerged metal. This is often seen when wire runs are near bilge water.

A typical circuit has positive wiring running from the battery’s positive terminal to the vessel’s fuse panel, through the wiring to the appliance. The negative cable from the appliance runs to a bus bar that is connected to the negative post on the boat’s battery. The circuit completes a circle from the battery to the appliance, and back to the battery.

But what if one of the wires is broken? Or a connector isn’t crimped properly, or isn’t watertight? And what if that wire runs through (or near) bilge water?

Bad Connections

Imagine instead a scenario where one of the wires running to automatic float-operated bilge pump was crimped, but not watertight. Current runs from the connection through the bilge water to a metal through-hull fitting. Current continues to flow into the water around the boat, through the propeller and shaft, to the engine block, which is where a common ground exists, and runs back to the negative post of the battery. The circuit is still complete, but through a much more irregular (and unintentional) route. Electricity is lazy and it will always find the most direct path to complete its circuit.

In this example, the voltage is relatively low: 12V battery power. But the result of this may be that the propeller, shaft, sail drive or sterndrive may become severely corroded within hours or days. Stray-current corrosion takes place at an alarming rate. A sterndrive can corrode to the point of falling off and causing the boat to take on water (and ultimately sink) in a matter of days.

Cures: Prevention and Mitigation

Prevention is a two-fold approach:

- Ensuring that proper electrical standards are being met: Support electrical-wire runs, prevent chafing and wearing of wire insulation, creating proper electrical connections and protecting with shrink-tubing to make sure that connections and terminations are watertight.

- Following the old adage: Electricity and water don’t mix — keep wire runs out of the bilge and away from areas where water is likely to intrude or sit.

Mitigation is your back-up plan. A boat is surrounded by water while the comforts that electricity provides can’t be ignored. There’s a way to meet both needs and still get a good night’s sleep: electrical bonding.

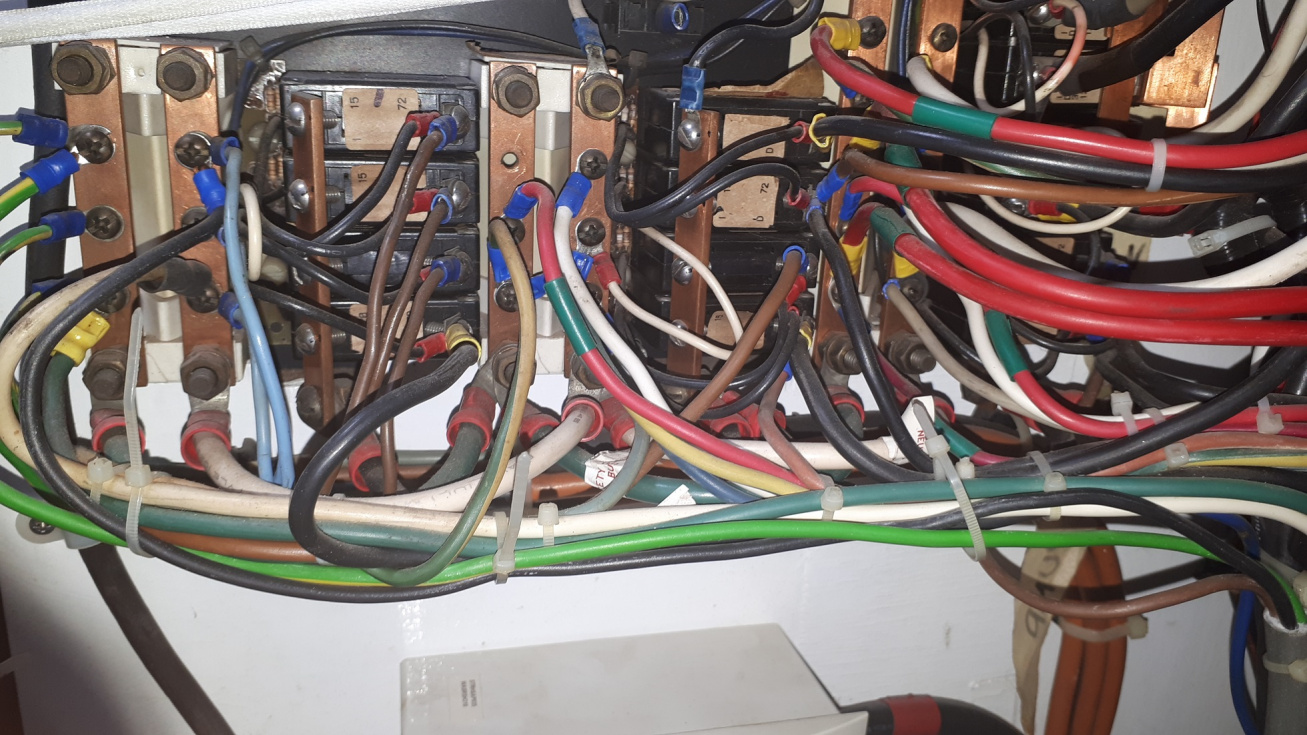

An electrical bonding system ties together all of the components that may allow stray current to flow, providing a new path to let electricity to flow back to its source. In simpler terms: a wire (typically 8 AWG, and insulated in green) is connected to the metal casing of every appliance, through-hull, keel bolt, mast step and bracket that may be exposed to bilge water. These wires all run to a common bus bar that is tied in to the boat’s negative ground system.

This means a different result in the catastrophic scenario described earlier: one of the wires running to the automatic float-operated bilge pump was crimped, but not watertight. Current runs through the bilge water to a metal through-hull fitting. Current flows through the through-hull fittings bonding wire to the boat’s bonding bus. Current continues to flow to the DC negative bus, and then runs back to the negative post of the boat’s battery. The stray current still occurs, but without any damage.

It's never ideal for current to stray from its intended path – and performance changes will be noted: the voltage drop from current not reaching its intended source may not allow certain appliances to function – triggering an investigation. A great place to start is by measuring current flow through the bonding bus bar. Any current flowing here indicates that stray current is happening.

Raising the Stakes

Earlier, I mentioned that we’re talking about DC 12V battery voltage — and this is where most of the stray-current corrosion takes place on boats. If the same broken-wire scenario were to take place in the AC 110V system, the entire boat (appliance casings, railings, mast, wire rigging, stays, faucets, hand rails, engine blocks, etc., could be energized with 110 volts: in short, enough to cause severe injury (or death). Luckily, AC systems have a “built-in” grounding wire that provides similar protection as the DC bonding system described. That said, if that grounding system is broken, faulty or disconnected, the water around a vessel (or between boats) could become energized with 110V. In fresh water, a person swimming between vessels can suffer paralysis or death with this voltage. In terms of corrosion, the vast majority of cases involve faults in the DC 12V system.

Most boats produced after the 1980s have a 12V bonding system already installed. If you’re breathing a sigh of relief, good. The protection is already there. The problem is, bonding systems on boats are notoriously overlooked. These wires, by their nature, run in the darkest and dampest parts of the boat in out-of-the-way places. Because of its “back-up” use, the bonding system is rarely checked, maintained or tested. Wires are often broken or corroded. Additions or changes to the original production set-up of the boat may not be bonded correctly to the rest of the system.

Electricity is lazy, yet predictable. It can be tested, verified and repeated. If you’re noticing voltage drop, corrosion or other performance issues (especially right after a change or repair to your electrical system), always have the system checked by a qualified marine tech.

Andrew McDonald is the owner of Lakeside Marine Services – a boat repair/maintenance firm based in Toronto. Andrew has worked in the marine industry for 12 years and is a graduate of the Georgian College Mechanical Techniques - Marine Engine Mechanic program.