Diesel Engine Spring Commissioning

Ah yes, spring is in the air. Sunshine, chirping birds, flowers — all of the traditional cues that turn a boat owner’s fancy towards spring commissioning and preparation for the boating season. An important part of this spring ritual is awaking that diesel engine from its long winter’s slumber. Let’s take a look at how to properly roust and ready it for new adventures in the upcoming season.

Use a Checklist

Before starting any major evolution, grab a cup of coffee and take a few moments to step back and view the engine and its associated systems as a whole, noting any obvious problems such as leaks, excessive rust, or broken components (this should also be a part of the fall decommission routine as well).

After addressing any obvious issues found during the above, it’s time to run through that spring commissioning checklist every boat owner should have. Don’t have one? No problem — here’s a list to help get started. It’s not all inclusive, but it provides a good baseline to work from, one that can be personalized using the engine service manual.

Engine Oil Change

Change the engine oil and filters per the manufacturer’s instructions. Regardless of the hourly recommendations, engine oil should be changed at least yearly, however opinions vary on the best time for this annual oil change. Some advocate during spring commissioning (to start the season with “fresh” oil), but most mechanics and engine manuals recommend changing oil during the fall layup, so that the corrosive acids and carbon generated during combustion are not allowed to remain in the engine over the winter. If any doubt exists, it can always be changed in the fall and spring — no engine has ever been damaged by too many oil changes.

- Always run the engine up to operating temperature prior to an oil change. Warm oil is easier to change and it holds more contaminants in suspension, helping to rid the engine of more grit and grime.

- If an engine uses a spin-on oil filter, apply a thin film of oil to the gasket and hand-tighten when replacing. If the filter is a cartridge type, ensure the O-ring gasket is properly seated before reinstalling. Filters should also be topped off with clean oil before starting the engine.

- Date the oil filters with a permanent marker to serve as a visual scheduling reminder.

Belts

Inspect all belts for signs of damage or deterioration and proper tension. Using a thumb, apply moderate pressure halfway between pulleys — the belt should deflect around 3/8” (.95 cm) depending on its length. Replace cracked, fraying, or delaminated belts and always keep at least one spare onboard for each.

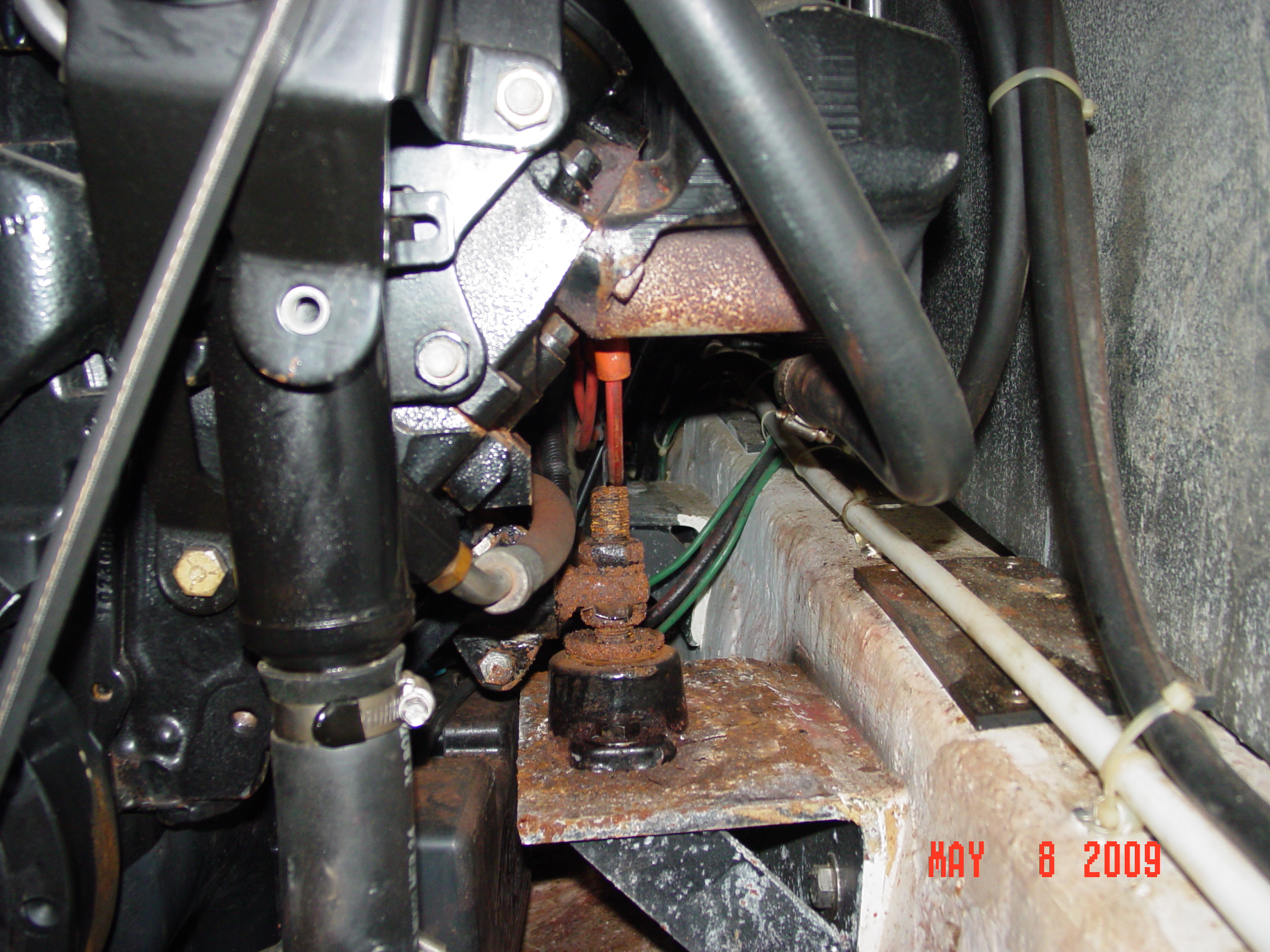

Mounting

- Check engine beds and mounts for cracks, broken bolts, or looseness. Worn, failing, or undersized engine mounts can cause a multitude of problems, such as shaft misalignment, which can lead to vibration, shaft damage and failure of other components (cutless bearings, stuffing boxes, transmissions, or even the hull itself). If the engine mounts are the vertical stud type mounted in a solid rubber base, check that each is properly centered. If cocked or leaning to one side, the mount is stressed and the drivetrain system needs alignment.

- While inspecting the rear engine mounts, give the propeller shaft a strong tug horizontally and vertically to detect any looseness or wear in the transmission or stern gland.

Transmission

Check the transmission oil level, making sure all plugs are secure and no leaks are present. Change the transmission oil per the manufacturer’s recommendations.

Finally…

- • Verify proper operation of all engine alarms, gauges, and indicator lights – verify and compare gauge readings at each helm position.

- • Provide chafe protection for all engine and generator hoses and wiring where necessary.

- • Place absorbent pads beneath the engine — they help keep the bilge clean and make any leaks more noticeable.

Reading the Smoke Signals

When cranking an engine after its winter nap, paying attention to the exhaust can help spot a number of potential problems. A well-maintained engine may smoke when initially cranked or while idling, but it typically won’t do so under load. White smoke during startup of a cold engine is normal, but it should clear up after the engine warms. If it continues, it normally means unburned fuel. Common causes of white smoke are cold ambient air, water or air in the fuel, water in the cylinders, a faulty injector or injection pump, incorrect engine timing or poor compression.

Black smoke upon startup is common as well, but its presence after the engine is at load indicates incomplete combustion. Possible causes include air intake or exhaust restrictions, compression problems, lousy fuel, faulty or worn injectors or the engine not reaching its normal operating temperature (for example, a stuck thermostat).

Blue smoke means the engine is burning oil, which is also not uncommon at startup. Continued smoking may indicate trouble with valve guides and stems, worn piston rings, failing turbo-supercharger oil seals or excessive oil level in the engine. In Part 2, we'll look at commissioning tips for engine-related systems.

By Capt. Frank Lanier

Captain Frank Lanier is a SAMS® Accredited Marine Surveyor with more than 40 years of experience in the marine and diving industry. He’s also an author, public speaker, and multiple award-winning journalist whose articles on seamanship, marine electronics, vessel maintenance and consumer reports appear regularly in numerous marine publications worldwide. He can be reached via his website at www.captfklanier.com.