Electrical Installation, Part 3: Grounding and Bonding

Electrical ground is a term used to describe the reference point in an electrical circuit from which voltage is measured, a common return path for electric current, or a direct physical connection to the earth.

Connection to ground is also important to trigger protective mechanisms in the event of failure of internal insulation and limits the build-up of static electricity.

The term ground can be misleading because the term in also used in cell phones, cars and boats, none of which are connected to the earth. A different but suitable term is common. A common connection is usually a large conductor (wire) attached to one side of the power supply. The black (negative) conductor running from the boat’s battery to the engine block, could be called common rather than ground.

Why is a Ground Important on a Boat?

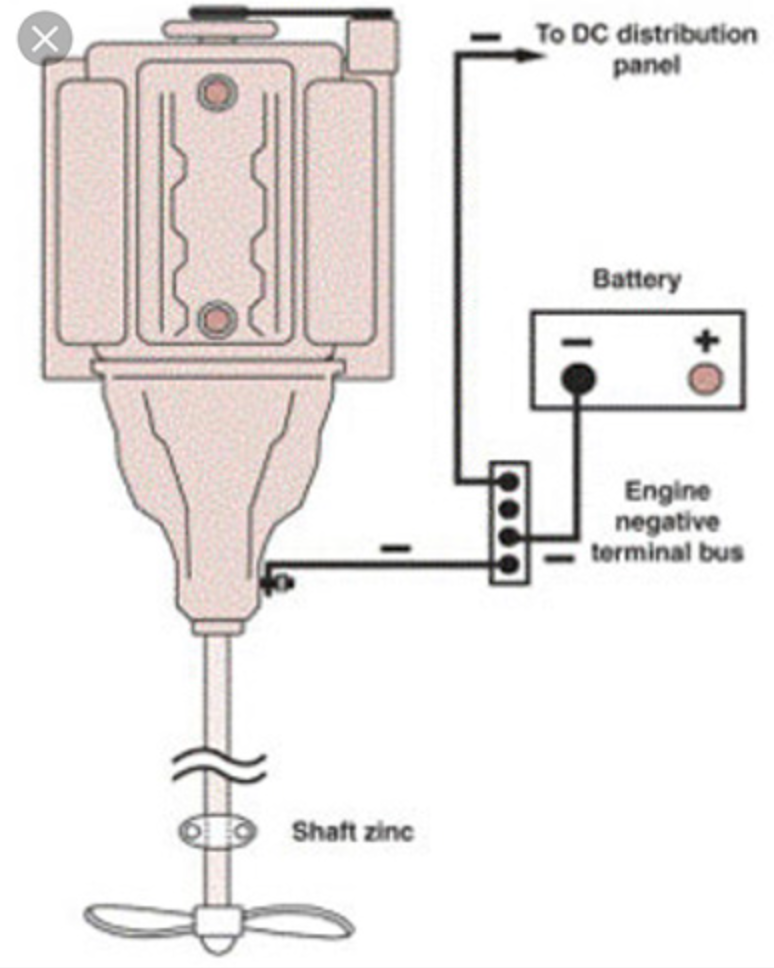

If an electronic device develops a short-circuit from the power-supply side to the equipment’s metal case, the case would then be “hot” and would be a potentially dangerous source of electrical shock or ignition. By “grounding” each appliance (whether AC or DC), you provide an immediate and easy path for the electricity to travel, eliminating the danger of shock and ignition (and reducing the possibility of corrosion). On a boat, this path to ground is generally to the engine block. A typical set-up on a boat includes a heavy-gauge cable running from each negative battery post to the engine-block grounding post. Each electrical appliance is grounded to a main bus bar and the bus bar is grounded using a cable running to the engine block grounding post.

A Few Important Notes About This Setup

- Each cable used should be checked against an ampacity chart (discussed in part 1 of this series) to ensure that the cable size is correct given the amount of current being carried and the length of cable run.

- Each cable should be secure and torqued to specifications using appropriate connections (discussed in part 2 of this series).

- Grounds should be checked periodically using a multimeter. This ensures that short circuits, corrosion and loose connections haven’t crept in, reducing the effectiveness of the grounding efforts.

Bonding is a similar but distinct term. Bonding is the practice of electrically tying together all the large metal objects on a boat. This serves multiple purposes, preventing corrosion damage, providing lightning and ignition protection and serving to reduce static electricity buildup. The items commonly tied together include fuel tanks, metal casings (water heaters, as an example), keel bolts, propellers/shafts, engine, transmission, sterndrive and mast steps.

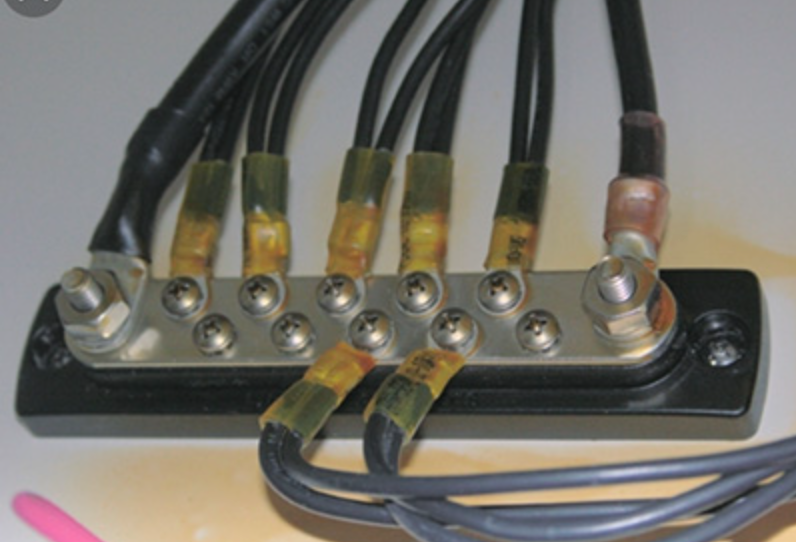

The key to a good bonding system is the use of short-runs with high-conductivity wiring: tinned-copper wiring, of at least #8 AWG (6 AWG if lighting protection is desired) is the suggested rule of thumb. Many bonding systems employ multiple bus bars or a common grounding conductor to keep these wire runs as short as possible. The bonding cables used to connect electrical equipment (AC and DC panels, as an example) should be larger than the current-carrying wiring in the circuits. If there is a short to the equipment casing, the bonding cable may carry current — and the cabling should be large enough that it won’t melt and start a fire.

A typical setup involves each component being bonded separately. This means that components aren’t wired in series. Instead, each component should be bonded individually to a common ground bus that connects via heavy gauge cable to the battery negative post.

A good bonding system has various-sized conductors to account for each application. Each component is bonded individually and any bonding conductors should be rated to carry current, even though carrying current is not the purpose of bonding.

It’s particularly important to review grounding and bonding on a boat that has had any equipment changes, electrical upgrades or installations or significant changes to wiring. Older boats often have incomplete or partial grounding/bonding and therefore don’t function to protect the boat. Winter layup is a great time to review systems to make sure that they are installed correctly and are functioning as designed.

Article courtesy of Canadian Yachting magazine

Andrew McDonald is the owner of Lakeside Marine Services — a boat repair/maintenance firm based in Toronto. Andrew has worked in the marine industry for 12 years and is a graduate of the Georgian College Mechanical Techniques - Marine Engine Mechanic program.