Engine Room Inspection: Part 2 - Watch Those Temperatures

In Part II of our detailed look at engine-room inspections for inboard and sterndrive powered boats, we look at the concerns that come with temperatures of components and fluids getting too high. Early on, boat manufacturers were notorious for not supplying adequate engine-room ventilation and cooling systems, but that has improved over the years.

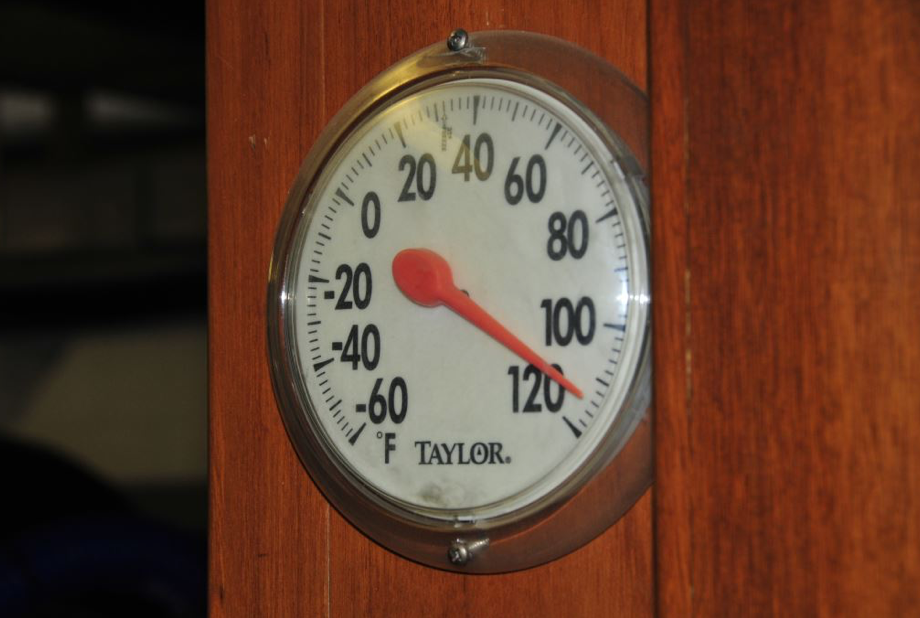

Engine Room and Related Temperatures: Measurement of engine-room temperature is an important metric for determining the efficiency and adequacy of the space’s ventilation, be it passive or active. Measuring this in different locations will yield different results, however. Most engine manufacturers specify a maximum allowable difference in temperature, a ‘delta T’, between the engine-air inlet, typically measured at the air filter, and ambient, the air outside the vessel (the outside temperature must be measured in the shade).

While Cummins and John Deere specify 30°F (17°C), Caterpillar’s requirements, as well as those of ISO 8861, are more stringent, they call for a maximum delta T of 22.5°F (13.5°C). If engine air inlet, and thus engine room, temperature is too high, the engine efficiency can suffer. However, a more insidious side-effect involves the accelerated deterioration of a variety of engine room components, including hoses, insulation, plastics and electrical/electronic components.

While it’s hard to say just how much of an effect temperature has on this gear, one example is telling. The potting on many generators’ electronic voltage regulators hardens, and cracks, which ultimately leads to failure when exposed to extreme engine room heat. It’s the thermal canary in the coal mine and is worthy of your attention; because the electrical end of a generator is air-cooled, hot engine rooms equate to gear, which isn’t good for its lifespan.

Engine air intake temperature should be measured using a wired (wireless is OK if not too bulky), digital probe type thermometer, (the one I use, made by Extech, is often used for fish tanks, it costs about $20), ideally with the probe suspended just above the surface of the filter element. While it’s tempting to use an IR thermometer, doing so will measure the temperature of the filter element itself, rather than the air passing through it; in testing I’ve done I’ve measured a disparity of as much as 7°F (4°C).

Diesel fuel is at its best when cool, at least comparatively so, it is denser, packs more BTUs per gallon and has a higher viscosity, and therefore greater lubricity. Fuel also acts as a heat sink, carrying heat away from fuel injectors (and to the fuel tank, more on that in a moment). Keeping fuel cool is deemed so important by some engine manufacturers that they incorporate raw water fuel coolers into their fuel systems.

Fuel Temperature

While you may have little control over fuel temperature, it’s a good idea to keep an eye on it, as a change could be an indication of a fuel routing, or fuel cooler problem, or another impending failure. It can be measured using an IR pyrometer, at the secondary filter (that’s the one on the engine). “Normal” fuel temperature varies with climate, seawater temperature if it is seawater-cooled, engine-room temperature, engine manufacturer, so it’s difficult to give a generic range. Keeping track of yours will allow you to identify a change.

As an aside, the heat the fuel removes from the injectors goes to the tank and it’s close to the hull. As a result, it is transferred, albeit inefficiently, to the water in which the vessel is operating. If the fuel tank is located in the engine room, some of that heat will radiate into that space, thereby adding to the load imparted on the ventilation system.

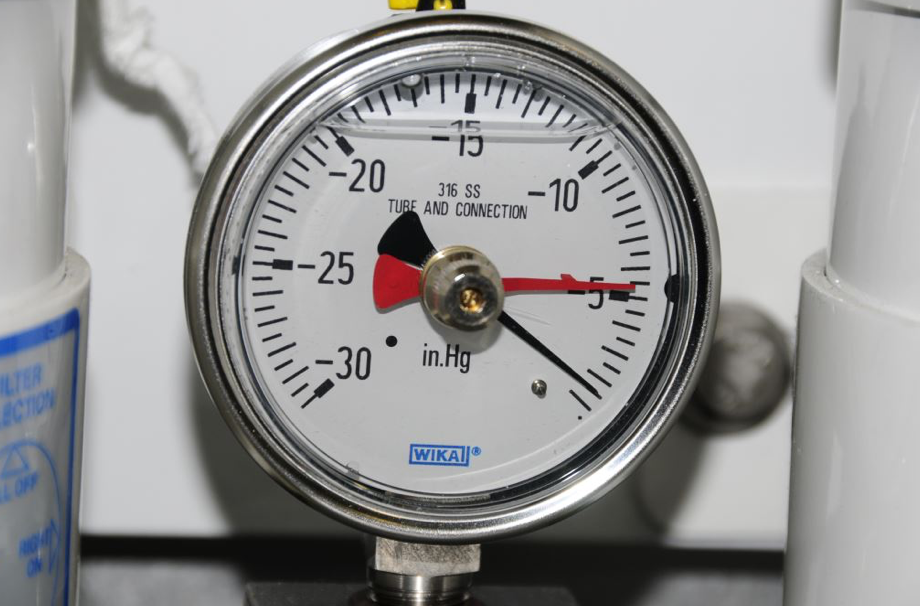

Indirectly related to fuel temperature is fuel vacuum. Many diesel-powered vessels have vacuum gauges installed at the primary fuel filter (the one off the engine). If it’s one of the common Racor MAXX tandem series, with the selector valve, the vacuum gauge is standard equipment. The primary reason for monitoring fuel vacuum is to determine the condition of the primary filter. As it captures more and more contaminants, the vacuum rises. Each engine manufacturer has its own threshold for allowable fuel vacuum; however, the general rule of thumb is it should not exceed 5” (12.7 cm) of mercury.

Not all vacuum gauges are created equal, so do some research before selecting one if there isn’t one on your boat.

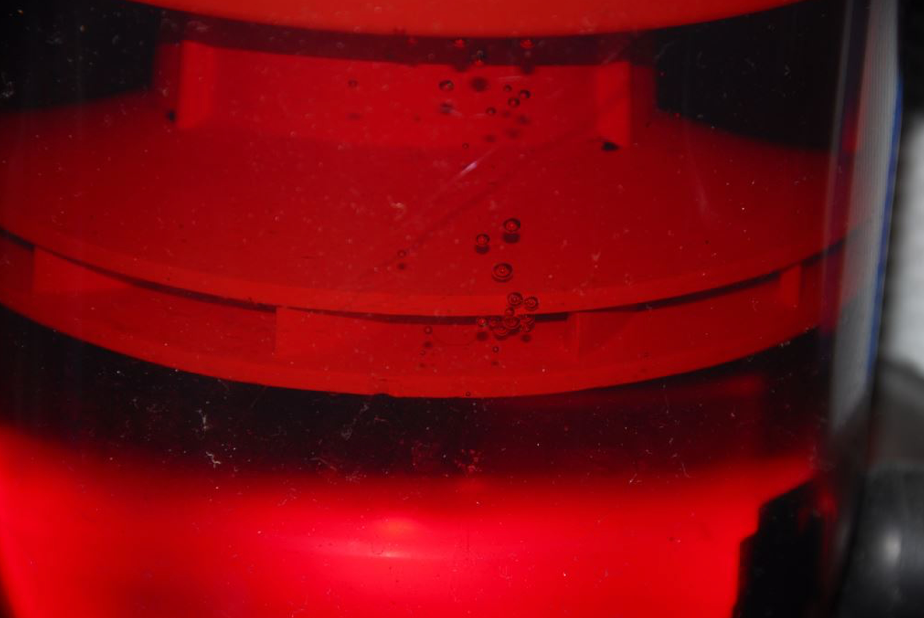

While you are at the primary fuel filter and assuming it is a Racor turbine series, look closely through the bowl, and at the ports in the coalescer cone, you should see no bubbles streaming upward from any of these openings. Bubbles indicate a vacuum leak and air ingestion, which could affect engine operation, and in great enough volume could lead to an unanticipated shut down.

Stuffing-box temperature should be regularly checked because an overheat can lead to leakage, in some cases catastrophic if a non-metallic dripless stuffing box melts and seizes to the rotating shaft. While the rules for allowable temperature vary for different dripless stuffing box manufacturers, I have found that both conventional and dripless boxes, when properly plumbed, typically do not run over about 40°F (22°C) above seawater temperature. Because an IR pyrometer can be confused by the reflective nature of a propeller shaft, or rotor of a face seal stuffing box, be careful to keep your measurements confined to the packing or stationary seal area.

If your vessel is equipped with a hydraulic system for stabilizers (and often thrusters as well), the temperature of this fluid should be monitored. It’s important to remember that if you have a hydraulic stabilizer system, the pumping action generates heat, which must be removed from the system via a heat exchanger, which is usually located near, or even within, the fluid reservoir. If that heat exchanger utilizes a dedicated seawater pump, and it fails, or the strainer becomes clogged, the hydraulic fluid will eventually overheat. If that happens, the hydraulic pump may be damaged or worse, it may seize.

If the pump is “live” meaning it cannot be disconnected from its driven source, the engine timing or transmission gear, via a clutch, the seizure will almost certainly result in severe damage to the engine or transmission. The same scenario would occur if you were to lose hydraulic fluid, because of a leak or burst hose, albeit far more rapidly. If your hydraulic system begins to overheat, you should get an audible alarm before it becomes critical. Regardless, if you cannot disable the hydraulic pump(s) via a clutch, you will need to resolve the cooling problem or stop the engine. Unbolting the hydraulic pump from its power take off (PTO) drive is yet another option.

You can measure the hydraulic fluid temperature by scanning the tank with your IR pyrometer and recording the highest reading, which will likely be closer to the top of the reservoir. It varies by application; however, I rarely encounter temperatures greater than about 135°F (57°C).

Running Gear: Beginning with the transmission, conduct a visual inspection, looking for leaks, signs of unusual vibration or loose hardware (hint; loose mild steel components such as fasteners and brackets, will generate a very fine brown halo around vibrating part; if you see that be sure to check carefully for something in the vicinity that’s loose). Take a temperature reading on the oil filter if present, and if not on the casing (wave your IR pyrometer around the case in the scan mode looking for the highest temp).

If your engine has a wet exhaust system, then the transmission will usually be raw water cooled, which means it will run somewhere around 150°F (66°C). If, on the other hand, you have a dry exhaust, then the transmission will be jacket water cooled; it will therefore run closer to the coolant temperature.

If your vessel is equipped with a thrust bearing, an Aquadrive, Seatorque, or similar system, measure its temperature using your IR pyrometer. The primary goal here is to measure the thrust bearing housing; if it’s out of alignment its temperature will be elevated, as well as universal or CV joints, whichever of the two it may have. Temperatures for these components vary with the manufacturer and load so consult the manual for your equipment’s range, however, generally speaking Aquadrive thrust bearing housings rarely run over 170°F (77°C), while the CV joints themselves shouldn’t exceed 150°F-170°F (66°C - 77°C). Seatorque’s guideline notes a maximum temperature of 220°F (104°C), but they typically also run much cooler, somewhere around 185°F (85°C) in my experience. The U-joints will, over a longer run, operate at somewhere between 150°F-170°F (66°C-77°C).

Motor mounts should be inspected for obvious signs of movement or loose hardware. This can and should be done during every static engine room inspection, however, you can’t look them over too often. If you can access them safely while underway (outboard mounts on twin engine applications may be tough to get to), then do so. Look as well for accumulations of rubber dust, an indication that the rubber of deteriorating, or metal to metal contact bet floating and stationary metallic parts or fasteners, which is often the result of collapsed flexible inserts.

Watch the shaft to ensure it is turning true and not wobbling from side to side; this is most easily observed by watching the stuffing box. A wobble can be caused by several defects, among these a damaged or fouled propeller, a bent shaft, a shaft that is not centered in its coupling, or a coupling that is not centered in the transmission’s output flange pilot bore (the latter two are coupling defects that necessitate coupling replacement or machining).

Finally, check the vessel’s steering system. If it’s hydraulic and powered, via a PTO, then check the fluid level, temperature and pressure (the reservoir usually has a pressure gauge). Hydraulic steering systems that operate via an engine-driven pump typically utilize seawater cooling, the water for which is usually drawn directly from the engine’s own raw water circuit. In other cases, it may rely on a dedicated pump. Either way, monitoring the temperature is important, as an increase can be an early warning of a fouled heat exchanger’s clogged intake or damaged impeller.

The temperature can be measured at the filter or reservoir. If the system is purely manual, then conduct a visual inspection of the fluid level, the rams, plumbing, valves, tie rods, and fasteners that secure the ram end(s) to the tiller arm. Loose or worn fasteners, or clevis pins (these connect two moving parts, tiller and ram end) are among my most common finds when inspecting steering systems. Check the fasteners that secure the ram to the base or shelf on which it rests. This is best done when making turns, so plan on checking this while doing some S turns at cruising speed about every 100 hours of engine time.

I’m occasionally asked, “Do I need to check the engine room if I have a camera in that space?” The answer is yes, you do, there’s one thing a camera still can’t do, and that’s smell. If you have a coolant or fuel leak, you are very likely to smell it as soon as you enter the space.

Without a doubt, engine room checks pay dividends, as they enable you to catch problems before they become critical, which can endanger both the vessel, and your wallet.

By Steve D’Antonio

Beginning his career in 1988, as a marine mechanic, electrician, manager and partner of a custom boat building shop and two boatyards and technical journalist, as well as through Steve D'Antonio Marine Consulting, Inc, Steve provides personalized and hands-on service to boat buyers, boat owners, boat builders and equipment manufacturers, as well as others in the marine industry around the world. Steve is an American Boat and Yacht Council Certified Diesel, Electrical, Corrosion and Systems Master Technician/Adviser. To learn more or to contact Steve, go to SteveDMarineConsulting.com.