Faux-Teak Deck Coverings: Good Looking and Easier Maintenance

If you like the classic look of teak on your decks and sole, but don’t want to deal with the expense of real teak, you should take a look at one of a trio of synthetic equivalents.

Two are PVC-based — Tek-Dek and Flexiteek — and one is cork-based — MarineDeck 2000. Teak and exotic timber has been used in the construction of boats seemingly forever and although proportionally few timber boats are built these days the use of teak decks is still fairly common.

Once upon a time, a teak deck was the real thing. The teak was laid over deck beams and oakum or cotton caulking was hammered between the planks to make them watertight. Nowadays, with composite construction, a teak deck is purely cosmetic and a symbol of high quality. Teak decks are expensive in materials and labor to install and maintain and they present an environmental issue that worsens as time passes.

Many countries have bans and restrictions on importing teak. Kiln-dried, plantation teak is available but any boatbuilder worth his salt will shake his head and comment that the grain structure, oil content, density and lifespan of this fast-grown plantation teak is just not the same as old-growth teak. The limited amounts of quality teak available are protected or inaccessible, and rightly so, because the last thing our environment needs is us cutting down trees unnecessarily.

Alternative Choices

If you enjoy the look and feel of a teak deck but would like to protect the environment, save money and reduce maintenance time, take a look at the alternatives. For example, cork and synthetic decks are becoming much more prevalent, now appearing on superyachts, cruise liners and production boats. Also, synthetic deck materials are increasingly being used for DIY projects. Each alternative has different properties, so choose carefully. Polyvinyl Chloride (PVC) t is used by two of the world’s leading synthetic decking manufactures.

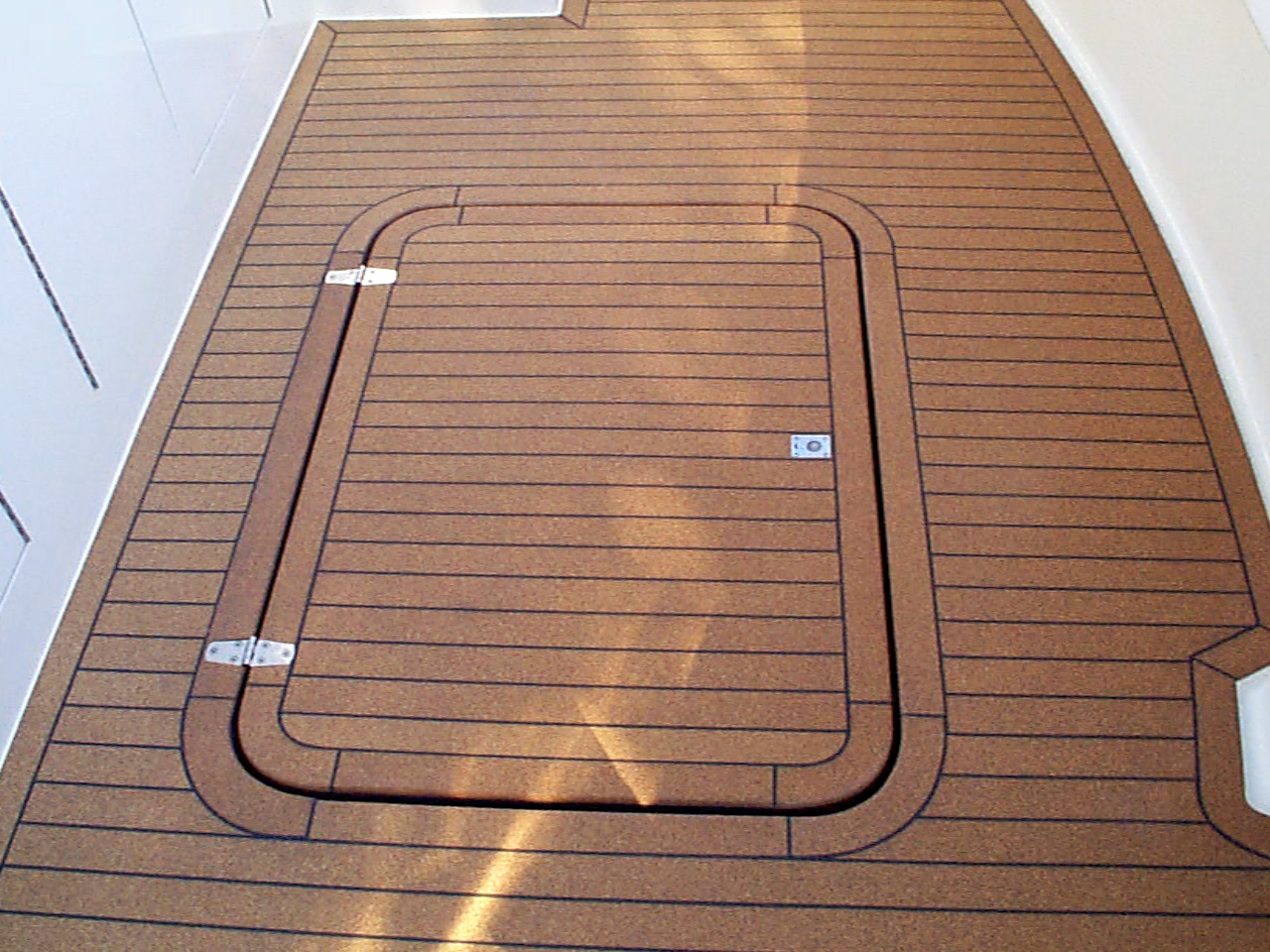

It looks and feels like natural teak and has some distinct advantages over the real thing in terms of installation, cost, and maintenance. Because synthetic teak decking measures just .2” (5 mm) thick, it’s flexible enough to conform to surfaces that aren’t flat. Install it by gluing it down to a clean surface with a two-part adhesive.

One considerable advantage of laying a synthetic deck as compared to a natural wood deck is that you don’t have to drill any holes for screws so the structural integrity of the underlying deck isn’t compromised. Installation is much easier than with real wood because synthetic decking can be cut with a sharp utility knife and most of the caulking required for teak decking is eliminated. Synthetic teak decking requires little maintenance — occasional washing keeps it in good shape. For surface damage, the decking can be sanded because the color and the grain extend through the entire thickness.

MarineDeck 2000

Unlike Flexiteek and Tek-Dek, MarineDeck 2000 makes no attempt to simulate natural teak grain. MarineDeck 2000 consists of highly compressed natural cork particles in a polyurethane binder. Cork, in this application, has superior thermal and sound insulation properties. It’s also highly resistant to damage from UV light, salt water and even chemicals. The pressed cork is cut into planks, that, once assembled, and seen from a distance, look remarkably like real teak decks. Installation is possible on any flat surface, in any marine environment, whether it is steel, aluminum, wood or glass/carbon fiber reinforced materials.

Cork has the advantage of being a greener product that does not kill trees because it is formed from the bark, which grows back. Cork is peeled off the tree every seven to nine years. Marinedeck 2000 is made from finely granulated cork, which is mixed with a polyurethane elastomer as a binder. A UV inhibitor is also added, before the mixture is cured in 20-ton presses.

Marinedeck 2000 is produced in 1.97” (50 mm) and 2.95” (75 mm) normal, 1.42” (36 mm) narrow, margin and 4.92” (125 mm) king plank widths. The planks are 6’2” (1.88) meters long and sold as a DIY system. Planks are laid individually and then caulked and sanded like a teak deck. Consumers can also by 1’4” (400 mm) wide sheets are also available for prefabrication by production builders.

Marinedeck 2000 can be coated with a finishing product, but it’s best left bare. The bare surface is better for traction and grip as well as being cooler to the touch when exposed to harsh, direct sunlight. In fact, a natural teak in direct sunlight in the down-under summer soon feels too hot to walk on barefoot, but Marinedeck 2000 does not. When wet, the top layer of cork granules absorb a little moisture, and this further improves traction. Cork is renowned for its thermal and sound insulation properties.

Flexiteek

Flexiteek is the original synthetic marine decking. Made of composite materials, Flexiteek looks and feels like real teak, yet is more durable, environmentally friendly, easier to maintain, UV-resistant and provides superior anti-skid performance.

Recently the company release Flexiteek 2G, a deck covering that weighs less and does not have the problems associated with other synthetic decking because it doesn’t get as hot. Flexiteek 2G cools 30% faster than traditional composite decking, allowing you to walk across barefoot. It is 35% lighter than other composite decking systems and is fully recyclable.

Instead of using a basic one-plank-wide section as a building block, Flexiteek offers multi-plank panels. Laying down several “planks” at a time is faster and easier than dealing with individual ones, but these panels don’t bend as easily as the narrower sections. The Flexiteek approach is best suited for applications where straight, parallel planking is required.

Flexiteek is not sold as a DIY system. Each deck is custom-made from a template to the exact shape and size and then supplied complete, ready to glue to the boat surface. Installation can be carried out by the boat owner or a trained installer.

Distributors build the decks by heat welding each flexible plank to the next and then adding details such as margins and hatches. This form of construction produces a strong, waterproof decking system. This method does not involve glue and there is no seam caulking that can break down or fall out. Flexiteek can be laid over any structurally sound substrate regardless of size, shape and location. It’s also sandable with individual graining. The result is a natural, realistic look and feel. The deck is stain-proof and can be cleaned even with a power washer. High grade UV stabilizers are used to ensure the decks stay looking like new. Flexiteek decks are .2” (5 mm) thick and available in a wide variety of colours, including Carbon, Off-white, Grey, Bleached or Natural Teak.

Tek-Dek

Tek-Dek has two composite marine-decking products, both of which are primarily designed to function as exterior, non-slip surfaces as a substitute for marine teak decking and other applications. The products are Tek-Dek Panels, more suited to DIY and professional installation, and Tek-Dek Professional marine deck material. Tek-Dek Professional combines hardwood fibers and thermopolymers into an extrusion that is hard, colorfast and almost indistinguishable from quality teak.

The hardness and dimensional stability allows the use of routers and planes to produce decks that can have a high level of detail and precision. Unlike many flexible systems, the rigidity of Tek-Dek Professional also means that deck fittings can be mounted through the deck without the chance of the material crushing. This feature also helps where the sub deck is uneven and can help even out some of the rise and falls.

Both are virgin PVC, tongue-and-groove extrusions designed to be glued together. The underside has a unique dovetail; these channels increase the surface area for chemical adhesion and provide a mechanical grip to the bedding adhesive. Tek-Dek International’s Custom Panels can be applied to almost any surface including GRP, steel and timber. Its flexible composite structure makes it non-slip and this feature continues even when the deck is running in salt water.

Ideal for either DIY or boat builders, Tek-Dek can also be supplied in easy-to-handle welded sheets. A craft knife and adhesive spreader are the only other tools required. Colorfast pigmenting and in-built graining are convincing. Combine this with the fact each strip actually includes its own dark caulking edge and the end result will look like something laid by a traditional craftsman. Unlike wood, Tek-Dek requires no further oiling, varnishing, sanding or scraping. Cleaning is simple and can be achieved using adhesive removal wipes.

Conclusion

With the large cost savings involved and environmental issues, teak alternatives are worth considering. Although each product gives a “teak deck look,” there are differences. The advantages of a modern synthetic teak deck include the ease of installation due to flexibility of the narrow strips, reduced material and labor costs and color retention. Non-skid properties of these composite decking materials are excellent due to the wood like finish.