The Future of Boating is Sustainable

by Jeff Hammond

Last week BoatTEST sent a crew to Amsterdam to visit the annual METS Trade Marine Equipment Show. After a Covid-pause of one year, the 2021 METS Trade show was bursting with two years’ worth of new products. The importance of METS is that the exhibitors’ new products point to the future direction of boating and this year’s show unmistakably pointed to a “sustainable” future. That means electric outboard motors, hybrid diesel and electric inboard drive systems, a move to high energy-density Lithium-ion batteries and a move away from oil-based products wherever possible

While it is hard for many Americans to grasp, Europe is leading the way to the future, and boating is just one small manifestation of what is going on. Despite the many nationalities, cultures, economic systems and languages, Europeans are taking global warming seriously. Local governments are often taking the lead, passing legislation to reduce, restrict, and eliminate emissions from ICE (internal combustion engines), and curtail the use of oil-based products wherever possible. European manufacturers of ICE engines such as Volvo Penta have announced plans to be all electric within the next ten years, and Volvo cars will be all electric by 2030.

Creating a necessity for sustainable power, governments such as the one in Amsterdam have passed laws requiring electric power on all boats using its canals, as well as a ban on ICE engines operating in its canals and harbors by 2025. Other cities, states and governing bodies around Europe are doing the same, all on their own timetable. Indeed, several lakes in Germany have required extremely low emissions, or no emissions from boats for over a decade.

Electric Outboard Motors are Coming

Despite the fact that recreational marine engines contribute only a small percentage to the overall harmful ICE emissions, this class of engines is generally being held to a high standard in Europe. Electric motors are an obvious solution, and the cost of entry into this field is relatively low, compared to creating and producing an ICE engine. The result is a proliferation of small companies which are working on producing electric outboards.

At METS, we counted no fewer than eight electric outboard, inboard and sterndrive motor companies in their infancy, trying to gain purchase among boat builders and distributors for the aftermarket. These nascent outboards range from 2.5-hp to one company claiming a 270-hp outboard. We counted at least three brands claiming to have the world’s highest horsepower outboard motor. With a single exception (Torqeedo), these electric outboard motor companies are largely being made by small private companies lead by electrical engineers who are often boating enthusiasts, and investors who are betting on the come.

Typically, these electric makers are out-sourcing virtually all of their components, and then engineering assembly and a workable system, but there are some exceptions. We found several companies assembling their own battery packs, and one that is actually making its own electric motor from scratch. The lower units (leg and gear case), are typically from existing manufacturers such as Tohatsu, Mercury, Suzuki and Oxe.

Mass Production is Elusive

Most of the electric outboard motors we saw at METS were prototypes, and some hadn’t yet even been used in a boating application. For the most part, only a few units had been made. When we asked the directors of these companies – usually the founders – several told us that they planned to manufacturer the outboard units themselves. Clearly, this may well be problematical for production of more than a relatively few units per month.

Torqeedo. The obvious exception to this in-house assembly being Torqeedo, which is the undisputed leader in the electric outboard field, because it has been manufacturing a wide range of motors for 15 years and says it has sold over 100,000 units. This company has both robust manufacturing capabilities and world-wide distribution. Torqueedo was purchased by the Deutz Group in 2017 which has given the brand engineering, financial, and assembly capabilities. The € 1.3 billion company manufacturers diesel, electric and hybrid power solutions, in addition to owning Torqeedo.

Vision Marine Technologies, another exception to what appears to be generally ma and pa manufacturing, recently signed an assembly agreement with Linamar, a large manufacturing company in Canada for the mass production of it’s 180-hp outboard motor. VMT has a number of units in the field and BoatTEST has been involved with on-board demonstrations of these motors.

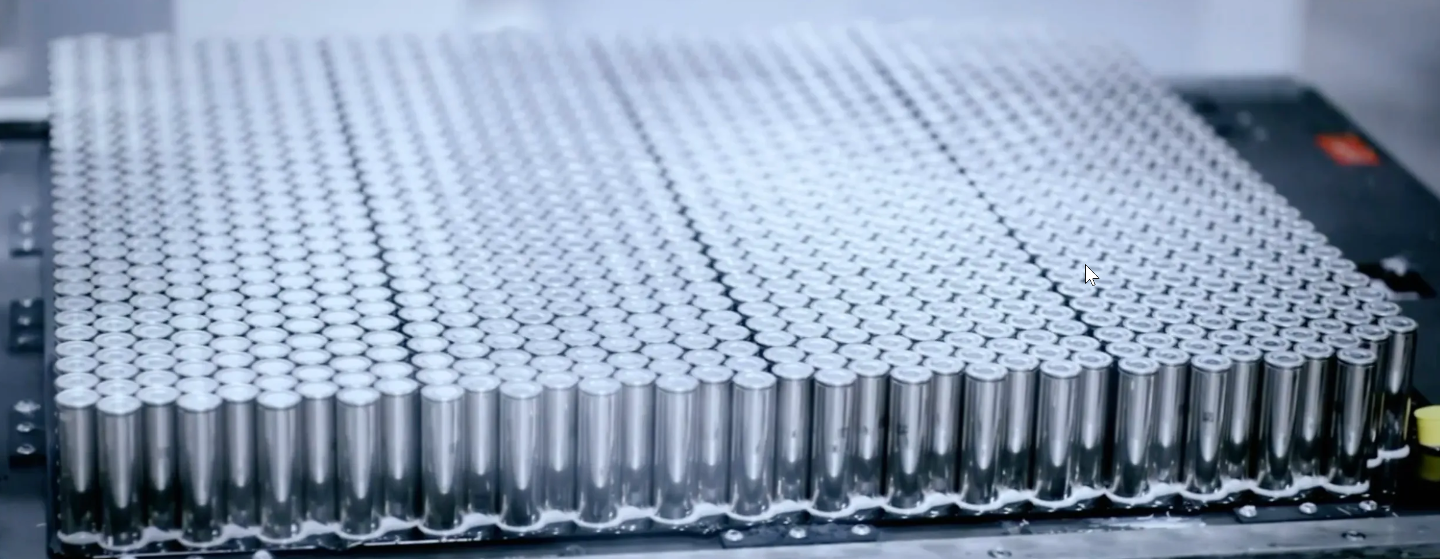

Lithium-ion Batteries Proliferate

Lithium-ion batteries are what make smart phones possible by being remarkably energy-dense for the size and weight of the batteries. While Sony invented the lithium-ion battery technology in 1991, Tesla Motors led the research 15 years ago into lithium-ion battery development for electric motors, and pushed its suppliers to make ever-better products. Today Tesla is generally regarded as having the best-in-class batteries, and the marine industry is taking note.

According to the International Energy Agency, 70% of the Lithium-ion batteries are sourced from China, in the form of small, generally tubular-shaped units similar to a flashlight battery. These batteries are then connected in parallel in a housing that may contain from fewer than 100 to thousands of cells, depending on the capacity desired. Companies have sprung up all over the world that manufacturer these battery packs, along with the all-important “battery management systems” (BMS) that go with them.

Surprisingly, a number of the outboard motor makers that we spoke with are assembling their own battery packs and engineering their own BMS controllers, claiming that they couldn’t find the specific characteristics they were looking for from 3rd parties which specialize in building the batteries and their controllers. It is also less expensive to assembly the packs in house, they say.

Overheating is the Danger

Because the battery packs are so energy-dense, they can overheat if there is a short or another issue, such as improper manufacture, damage, or a faulty BMS. This is the Achilles heel of lithium-ion batteries, because once they reach a certain temperature fire can break out in the pack spreading from one battery to the others creating a ‘metal’ fire that is difficult to extinguish, we’re told. This is a subject that is not much talked about, but the FAA has reported that there were 340 reported incidents involving smoking or burning lithium-ion batteries between 2006 and 2021 on commercial airliners.

Safety First. It is for this reason that the battery packs must be carefully engineered and assembled, making sure the connections between the batteries are secure, and that the batteries have a fail-safe system to eliminate runaway heating. In addition to a battery-pack engineering strategy for heat containment, the BMS is also critically important. Every lithium-ion battery we examined had them, usually sitting on top of the battery casing. In large lithium-ion batteries producing many kiloWatts of power, the BMS may be external.

More Power on the Way

Importantly, nearly everyone we spoke with involved with lithium-ion batteries told us that they expected energy-density to increase by up to 80% within the next year. If this comes to pass, it will have significant ramifications for marine use as it will increase the endurance of boats under electric power.

Now that virtually all of the worlds automobile companies are producing hybrid or all-electric vehicles, we can expect battery technology to make great strides forward.

Hybrid Power for Inboards

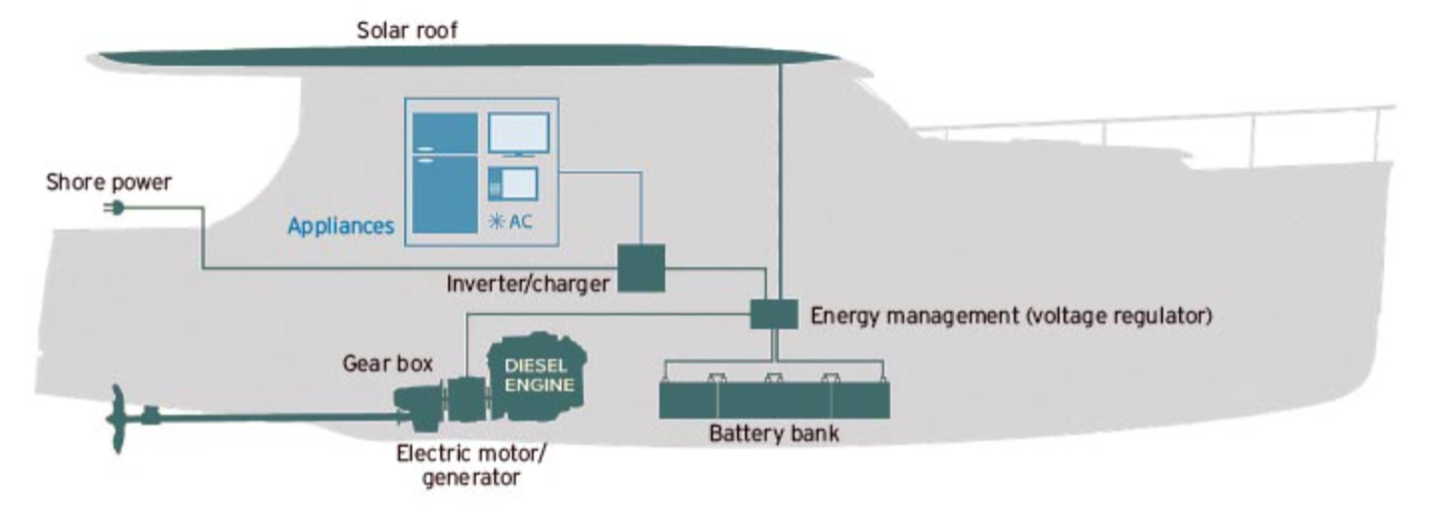

Hybrid power systems were very much in evidence at METS, and most of the systems on display are currently being used in commercial applications in Northern Europe. One company is specializing in retrofitting existing relatively small diesel engines in workboats and sailboats, with electric motors on brackets attached to the drivetrain for low-power propulsion. These seemed to be targeted to making water taxis in Amsterdam canals and small workboats entering the local harbor, making them compliant with the 2025 requirements.

The more robust OEM hybrid systems, typically place an electric motor/generator between the main engine and the transmission. The motor is powered by a lithium-ion battery bank for displacement-speed harbor operation. Diesel engines are employed when higher speed is needed to get to the fishing location, but then electric motors kick in when only slow-speed is required to do the actual harvesting. The combination of diesel and electric power makes for economical operation.

Greenline Yachts Leads the Way

Regular readers of BoatTEST are familiar with Greenline Yachts which for over 5 years has pioneered a hybrid diesel/electric motor system for cruising. In its yachts, the boat typically can cruise at 5 knots for 20 miles or so before exhausting its battery charge and then going back to diesel power – and at the same time recharging its batteries. (This is not a new concept, of course, and was used in WW II submarines by all countries to charge batteries when on the surface, then operate underwater on battery power when needed.)

Superyachts. Examples of hybrid power solutions at METS ranged from small water taxies to systems design for large motoryachts. In the Superyacht Pavilion were displays of hybrid systems which were more complex, some employing twin generators intended primarily to power electric motor propulsion which produce lower emissions than the mains.

To Hydrogen Power and Beyond

Hydrogen power solutions were not much in evidence in the Superyacht Pavilion, except in one display that we saw. Unlike the electric motor power solution which is starting in small vessels and will gradually transfer up to larger boats as battery technology develops, hydrogen technology may well be started in superyachts, then percolate down as technology is developed to make such a system possible in smaller boats.

This spring, Peter Lurssen, managing director of Lurssen shipyard, one of the leading builders of superyachts, announced plans to build a hydrogen-powered superyacht. Lurssen said the zero-emissions design will allow the vessel to travel 1,000 miles without releasing harmful pollution.

Continuing Coverage

BoatTEST is dedicated to keeping its readers informed about this exciting sea change in the character of boat propulsion. Stay-tuned every day in BoatTEST’s newsletter “On the Water” as we bring you exciting new details about the electric revolution as they develop.