Guide to Seacocks and Sea Strainers, Part 1

Every boat that brings aboard raw water to cool the engine, whether the raw water flows through the engine or through a heat exchanger, needs a completely dependable seacock or thru-hull fitting and a sea strainer or filter to prevent grass and other solids from reaching the pump.

If either of these small, simple parts fails, your boat can sink!

While the engine raw water pickup is the most obvious spot for a seacock and sea strainer, all other raw-water intakes on a boat also need similar fittings. Intakes for generators, marine heads, marine air-conditioners and washdown pumps are among the possibilities. Anywhere there’s a hole through the hull below the waterline, a seacock and sea strainer are a must.

Thru-Hull Fittings

Fittings that go through the hull below the waterline are obviously critical parts despite their small size and relative simplicity. A failure almost certainly means disaster if not discovered immediately, so quality parts and a flawless installation are absolutely essential.

Marine surveyors recommend yearly checks and routine replacement of thru-hulls every five years in saltwater, but more frequently for boats berthed in marinas where electrolysis is an issue. If you buy a boat older than five years, odds are good you’ll need to replace the seacocks—out of sight is out of mind for most owners.

Thru-hulls are most often made of bronze, which eventually corrodes in saltwater. The valve can also corrode enough that it can’t be closed, even though the fitting is still intact otherwise. If the valve won’t close and you have a break upstream in a hose or perhaps in the sea strainer, you have the same problem as if the thru-hull itself fails. Check the thru-hull valves regularly, grease them frequently and replace them when they get hard to operate.

The threading on thru-hulls and strainers is a bit tricky. Some fittings have straight threads top and bottom (NPS, for National Pipe Straight), and some have NPS bottom and National Pipe Tapered (NPT) at the top.

The tapered thread at the top is probably more common. It receives the tapered threads of tailpieces for the connection of hoses. Straight threads at the top are used when some other piece of hardware, like a strainer, is to be installed.

The important thing is to select parts that are matched for correct mating. If you use mismatched threads, while the fitting may be watertight when you install it, it may soon start to leak as the part works when the boat is underway, and corrosion will make the part fail sooner, as well.

Modern thru-hulls are provided with three-bolt bases for a secure installation. You can either drill an added three holes through the hull (with proper sealing compound around them, of course) or avoid the added holes and use a Groco Mounting Plate.

This is a fiberglass plate fitted for countersunk brass insets to allow installing the mounting bolts without a hole through the hull. The plate is expoxied to the hull. This is the preferred mounting by most marine pros.

Note that most thru-hull valves suitable for marine use are marine grade bronze, which is an alloy of mostly copper, tin, and importantly silicone. The latter element makes the metal much more corrosion- resistant and durable in saltwater use.

Some are also of a composite called Marelon, a high strength polymer developed to avoid issues with corrosion, the most common problem in brass and bronze fittings. Marelon is UL/ABYC approved and ISO certified. It can be used above or below the waterline.

No other composites are approved for marine use in thru-hull fittings below the waterline at this time.

There are not a lot of manufacturers making sea cocks—here’s a look at several of the best.

Sea Cock Manufacturers

Forespar is one of the few companies making approved Marine UL and ABYC standards composite seacocks and other fittings for use below the waterline. They use Marelon, which is completely corrosion proof. The NPS parallel threads can be sealed with Teflon® tape or plumber's putty.

Any marine-grade sealant or bedding compound can be used as with bronze fittings. Marelon and bronze fittings can be fitted together as long as the parts are not cross-threaded. Marelon is UV stabilized and will not deteriorate in sunlight.

They are considerably less costly than brass fittings, with the 1.5” size going for about $175; www.forespar.com.

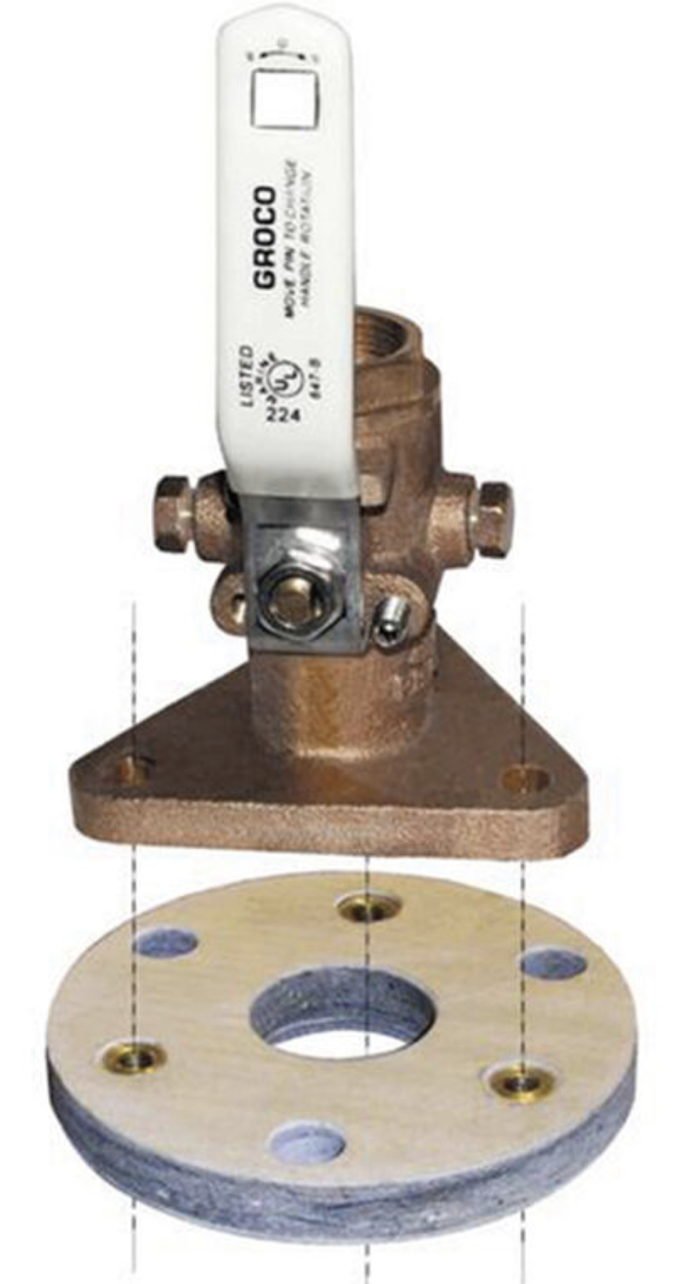

Groco makes a full line of well-respected thru-hull fittings including many with full flange bases for increased mounting strength as shown here. They also make mounting plates to fit, allowing installation without drilling added bolt holes below the waterline.

These are ball-type seacocks built to assure full flow to engines and generators. Price for a 3” (7.6 cm) model is $1309. They offer models down to ¾” (1.9 cm) which go for about $205; www.groco.net.

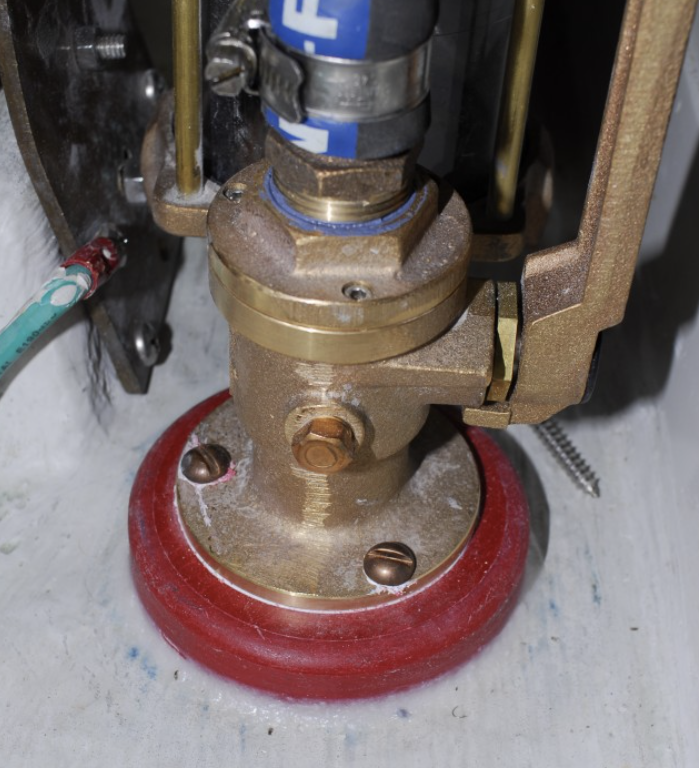

Perko makes a wide variety of cast bronze thru-hulls suited for all uses aboard, including the one shown here with a circular mounting plate and drain plug. The 3” model is about $1,270, while the smallest model, ¾” is about $200. A polycarbonate ball assures a tight seal and is less likely to corrode in place than bronze valves, the company says; www.perko.com.

Sea Seal, a British company, manufactures quality forged brass thru-hulls with grease fittings that make it easy to keep the valve lubricated. The company says their devices are forged, which strengthens the metal at the molecular level and produces a consistent, strong component not found in cast metals.

Their castings are made with Dezincification Resistant or DZR brass, which the company says will resist corrosion far longer than some alloys. The handles are reversible to allow ease of use in tight locations. Prices range from around $190 to $300; https://www.seaseal.co.uk