The Importance of Hose Inspection: Don’t Skip It

Does your boat have hardening of the arteries? Pardon the joke, but few people think in terms of vital arteries their boat. We’re talking about, of course, hoses and there are several on any modern boat. In some cases, a clogged artery can cause a fire. In others, a burst (or disconnected) hose can sink a boat in minutes. Old rubber hoses can harden when exposed exposure to heat, petroleum and water over time. Then they crack or fail.

Recently, a new problem called ethanol caused the interior wall of fuel hoses to collapse, inexplicably cutting off the fuel flow and disabling the boat. Older fuel systems were not built with ethanol in mind.

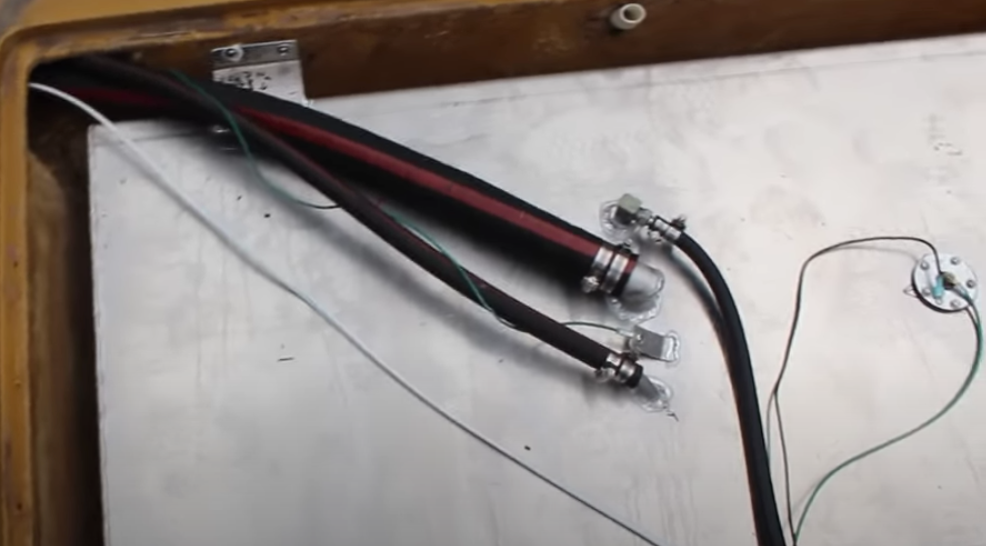

The arteries that are on your boat (even a small one) may include various forms of “marine hoses” including all flexible hoses, tubing, ducting, conduit, exhaust, connecters, fuel lines and even tiny engine hoses. Marine hose connects, services and protects virtually all the critical equipment and systems on the boat. It conveys fluids, vapors and gases and in other cases, protects wiring, cables and other connections. The failure of even one hose on a boat can have catastrophic effects like explosion, fire, flooding, sinking and more.

Types of Hoses

There is hose from the fuel fill to the fuel tank. The tank has a vent line that is usually a copper tube, a fuel hose from the tank to fuel-water separator or straight to the carburetor or fuel injection system and on diesel engines, there is even a return line to take unneeded fuel back to the tank.

The engine needs cooling water and that usually comes from a through-hull fitting or from the lower unit of a sterndrive to a hose that runs to the engine block or heat exchanger. Sometimes, more cooling lines are external to exhaust manifolds and, of course, almost all pleasure-boat inboard engines send their exhaust and cooling water through high-temperature hoses and out an exhaust pipe in the transom or through the drive unit and out through the propeller hub.

Larger boats also have hoses and fittings for running water in the galley, the head, a cockpit refreshment center or ice maker on the bridge.

All of these hoses are the vital arteries needed to circulate the fluids and gasses that make your boat work. And, they are relatively cheap compared to the costs of the systems they serve and protect. At least once a year, isn’t it worthwhile to patrol the boat’s interior spaces and engine room to police the condition of those hoses?

Don’t Forget the Clamps

What about the clamps that hold them on? Metal can fatigue and snap. Some hoses only have a two- or three-year life expectancy. After a long season of use, vibration, heat and fatigue, check all the clamps as well as the hoses.

“During my years in the US Coast Guard as a search-and-rescue pilot, I witnessed many disabled boat incidents that turned into tragedies,” said Bill Shields, president at Trident Marine Systems, who sell all manner of high-end hoses. “And there is no way of knowing if a hose failure was the root cause. But, as an example, the internal delamination of a marine fuel or water hose can be the root cause of an engine failure that leaves the boat disabled and drifting or worse.”

Tom Wise, Vice President for Corporate Development at North America’s largest marine hose manufacturer Novaflex, echoed the concern. “Inspect your hoses at least once a year,” he told us. “’All hose will fail in time’ is a comment I have made over and over. We are alarmed at how many boat owners take their hoses for granted, replacing them only when a leak or problem occurs. But by then, the contents of your fuel tank or holding tank could be sloshing around your bilge.”

Standards and Guidelines

The Society of Automotive Engineering (SAE) sets specifications for marine hose but we are told these specifications are generally not as stringent as those for automotive use. However, the National Marine Manufacturers Association (NMMA) and American Boat & Yacht Council (ABYC) standards are based on the SAE requirements.

A new SAE spec hose is fine when applied to the job it was designed for but among boat and engine companies, there is little incentive to use hose that exceeds the minimum SAE specs. From there, it’s all about price.

The hose needs to meet the minimum SAE specifications and survive the warranty period, which is often only one year. Some hose has a two-, three- or five-year warranty. When you get into high-end hoses like silicone exhaust hoses, there can be a 10-year warranty but that does not mean you can ignore the hose for 10 years.

What Goes On Inside

Wise also talked about ozone or O3, which is given off by most electrical current flow products like air conditioners, fans and so on.

He explained that the engine-room ventilation system in most boats (notably large cruisers) is designed to function when the boat is moving. When it is closed up tight at dockside, but an owner is running the air conditioning and other current flow accessories, ozone can build to high levels. The extra oxygen molecule in ozone makes it highly reactive and that greatly accelerates the hardening and deterioration of materials like rubber hoses. They can deteriorate in just a few months.

Rubber is cured from its natural gummy state with a combination of sulfur, peroxide, heat and pressure. Reliability and life expectancy depend on the “heat history” the hose has been exposed to. More heat increases the “cure” and causes the hose to become hard and brittle.

The hose may look fine until a big impact or other occurrence causes it to bend or flex. New hose is resilient. Old hose cracks or breaks. Imagine if that resulted in even a pinhole in a propane hose located in an enclosed space where a nearby appliance or switch could generate a spark.

Extreme cold during winter storage can cause rubber to go crystalline at -30 degrees and less. That can result in fractures at clamps and bends.

Don’t Skimp

Hoses are not expensive. Replacing them with new hose and clamps is easily within the scope of normal do-it-yourself projects. Your dealer can also do it and if you realize how little the cost difference can be, you might ask for high-end replacement hoses.

“I can tell you that our top quality hose is virtually all bought by consumers after they have experienced a failure,” Wise told us, “Then they are happy to pay.”

That makes good sense and then, if you have an older boat that is now exposed to ethanol or biodiesel products that it was not designed for, hose replacement and upgrades are essential. Do it in the spring or fall and carefully inspect all hoses and fastenings and replace any that are more than a few years old.