Inboard Exhaust 101: How to Keep Things Flowing

Familiarity with inboard engine exhaust systems is crucial for proper maintenance, as well as the safety of those onboard. Here’s how to inspect and keep an exhaust system operating properly.

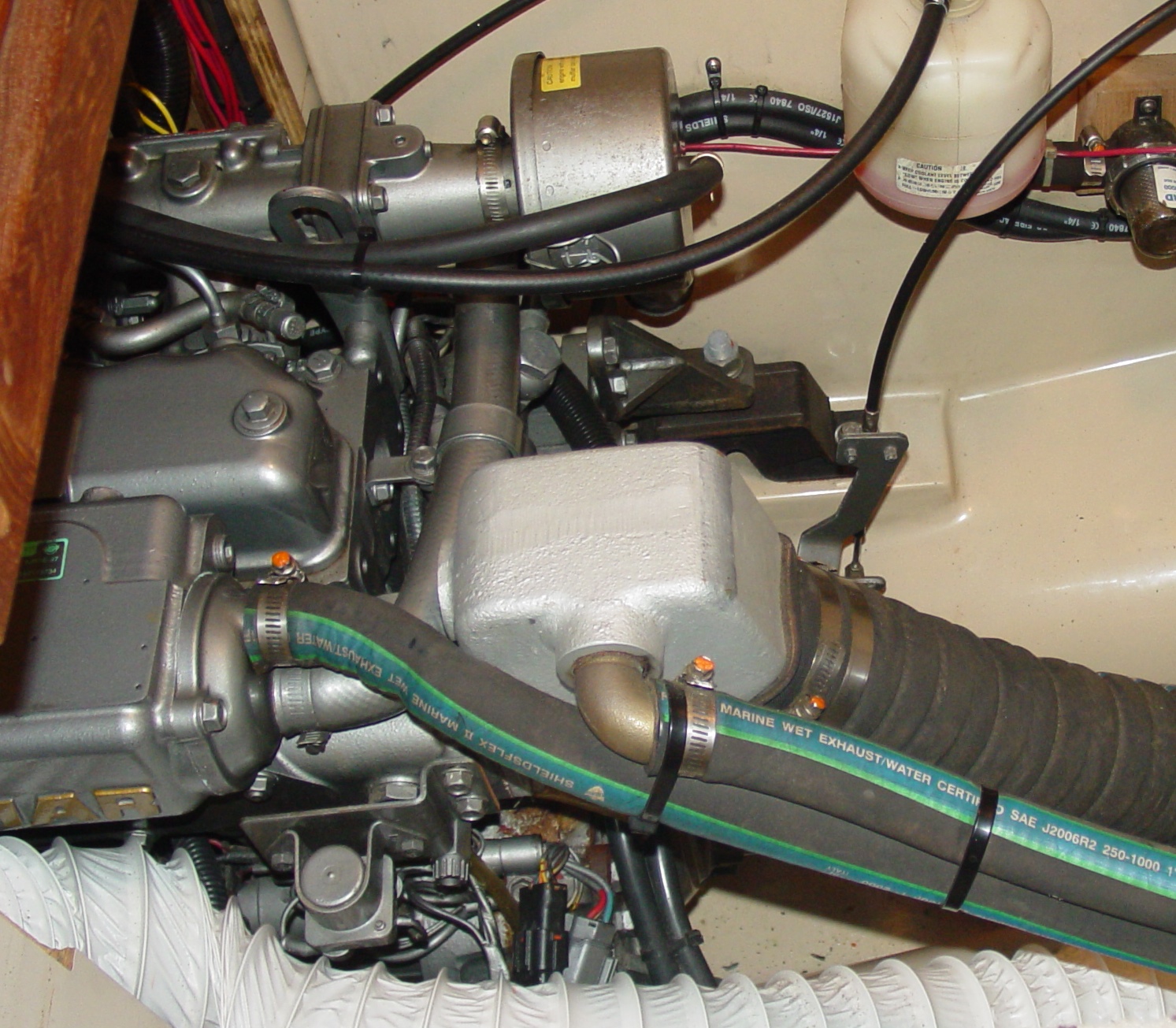

The wet exhaust systems found aboard recreational vessels use water to cool engine exhaust gases prior to discharging them overboard. The water also serves as a muffler of sorts to quiet engine noise.

How They Work

Water-cooled exhaust systems inject cooling water into the exhaust via a riser or mixing elbow, where the exhaust then pushes the water out of the exhaust outlet. Exhaust cooling water is typically provided by the engine’s raw water pump, although in some systems a second pump may also be installed.

Most installations also include a muffler located between the exhaust riser and the discharge outlet to reduce engine noise. The muffler provides a place for residual water inside system to collect (when the engine is shut down) as well as any stray water entering the exhaust outlet.

Maintenance Tips

A great familiarization and maintenance strategy is to conduct an inspection of the exhaust system at regular intervals, such as part of a fall layup or spring commissioning routine. All materials used in the exhaust system should ideally be labeled as to their suitability. Hoses for example, should be labeled “marine wet exhaust” and be able to withstand heat, water weight, pressure, oil and acids.

Anything other than short hose runs (i.e. four times the inside diameter of the hose) should utilize wire reinforced hose. Additionally, all hose connections should be made to a rigid component (pipe, muffler, exhaust outlet, etc.); hose to hose connections or joints should never be used.

Vessels with a transom exit exhaust should also have an exhaust valve, which is simply a rubber flapper valve that attaches to the outside of the exhaust, creating a one-way check valve to help prevent water (such as from wave action) from entering the exhaust and possibly the engine itself.

Some sailboat exhaust discharge installations may also feature a valve or seacock. This lets the system be positively closed to prevent water entry from following seas during offshore voyages when the engine is not utilized.

During an exhaust system inspection check hoses for leaks, kinks, chafe, bulging (at hose clamps), cracks and other signs of deterioration. Verify each hose is double clamped where possible (i.e. sufficient hose barb to allow it) and that hose clamps are tight and free from corrosion.

Hose clamps should be installed no closer than 1/4" (.64 cm) to the end of the hose and must fully engage the barb or fitting or damage to the hose can occur.

Heat-resistant lagging (insulation) covering hot or “dry” sections of the exhaust should be removed periodically to allow a full inspection of the components beneath.

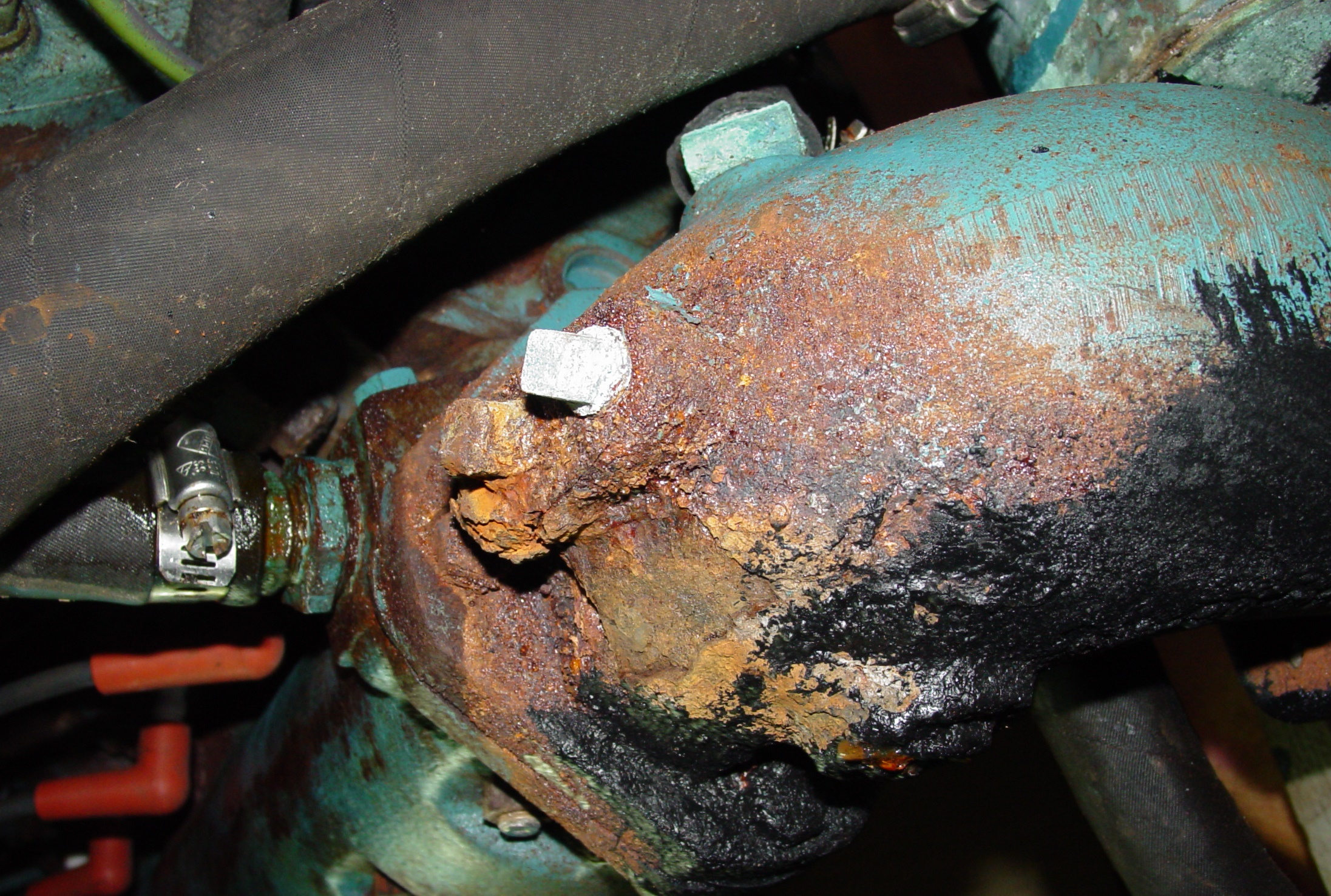

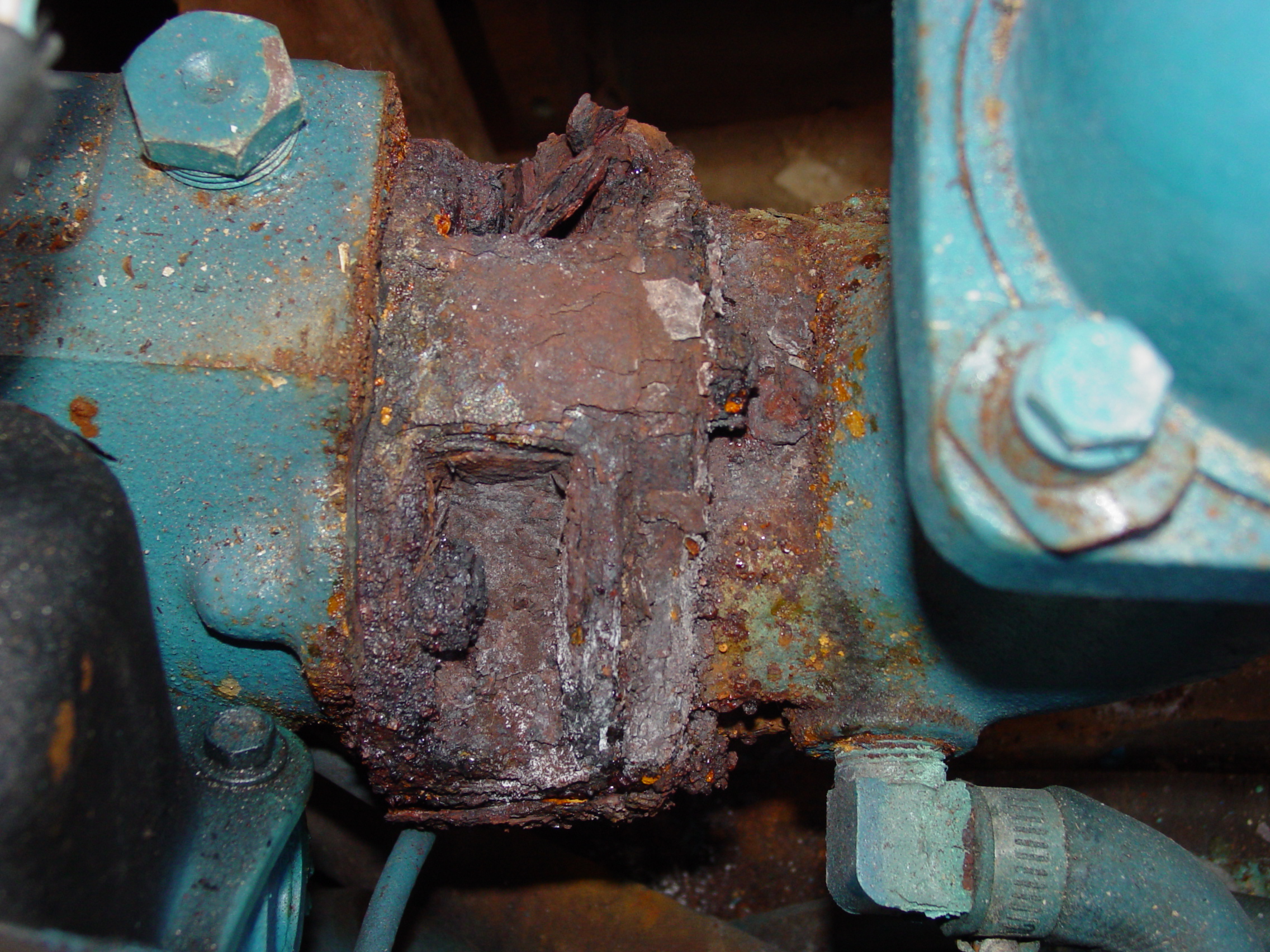

Keep a lookout for leaks at other system components as well, paying special attention to engine manifold and exhaust elbow joints (prime places for both leaks and corrosion).

Engine manifolds and exhaust risers should be periodically removed, pressure tested and inspected for internal corrosion and clogging, any of which can cause catastrophic engine failure.

This should be considered standard maintenance, particularly with systems operating in salt water. How often depends on the vessel’s environment (fresh or salt water) and use, however at a minimum they should be removed and inspected every four to five years (more frequently depending on age).

Because labor is typically the biggest cost associated with doing this, most boat owners will forego testing and simply replace old manifolds and risers once pulled regardless of condition, particularly if the vessel is used in salt water.

Finally, check the exhaust system with the engine off and while in operation because some leaks will only occur with the engine running.

Aside from maintenance, finding and correcting exhaust leaks are also important from a safety standpoint. They can introduce Carbon monoxide (CO) into the vessel’s interior with deadly results.

By Capt. Frank Lanier

Captain Frank Lanier is a SAMS® Accredited Marine Surveyor with more than 40 years of experience in the marine and diving industry. He’s also an author, public speaker, and multiple award-winning journalist whose articles on seamanship, marine electronics, vessel maintenance and consumer reports appear regularly in numerous marine publications worldwide. He can be reached via his website at www.captfklanier.com.