Installing an Automatic Fire Extinguishing System

A natural, first reaction after spotting those first tendrils of smoke wafting from an engine compartment is lifting up the hatch to see what the heck’s going on! Doing so however, provides a rush of oxygen that could easily turn a smoldering fire into an abandon ship type conflagration.

The first rule of successfully containing and extinguishing a fire is fighting it in a way that doesn’t make the situation worse. With engine compartment fires, the safest way to accomplish that is by installing a fixed automatic extinguishing system.

What They Do

A fixed fire extinguishing system mounted in the engine compartment provides quick, automatic discharge of extinguishing agent as soon as trouble starts.

Automatic is a key word here, but there should also be a manual discharge control located outside the engine compartment, enabling immediate discharge of the system in the event you or a crewmember spots smoke or fire before the auto-discharge mechanism kicks-in.

An audible and visual alarm at the helm (to alert you in the event the system discharges) is also desirable.

How They Work

Automatic extinguishers use mechanical triggers (glass, metal, etc) which break or melt at a predetermined temperature, typically around 165 degrees Fahrenheit. The ability to manually discharge the system is also a highly desirable feature. This allows a vessel’s crew to manually discharge the system in the event smoke or a fire is sighted, but temperatures are not yet high enough to activate the automatic trigger.

Once the system is activated, clean extinguishing agent is then released, flooding the entire engine compartment and extinguishing the fire. This is a much more efficient delivery system than the point and shoot method required when using a portable extinguisher. The term clean in this case means the agent leaves no residue.

The residue from a dry chemical extinguisher not only creates a huge mess, but is so corrosive that in some cases it can actually cause more engine damage than the fire itself.

Today’s automatic systems utilize fire suppressant agents such as FM-200, FE-241, or HFC-227. Halon was the clean agent of choice in the past, but while more effective, it’s also an ozone-destroying chlorofluorocarbon.

Although there are still lots of halon systems still in operation, new production of halon has been banned since the mid-90’s.

Sizing Your Unit

Fixed fire suppression systems can be customized for a particular vessel, but most boater owners will simply buy a pre-engineered off the shelf system, which is both cheaper and easier to install.

The first step in planning a fixed system installation is figuring out how large a unit is required to service the space. Start by calculating the cubic volume of the engine compartment, which can be found by multiplying its length x width x height.

If the space contains large items such as fuel, water or holding tanks, you can calculate their gross volume and subtract from the overall cubic volume of the engine compartment (giving you its net volume). I recommend simply ignoring this reduction in space however, as it adds an additional margin of safety by providing more extinguishing agent.

After calculating the volume of the engine compartment, refer to the extinguisher manufacturer’s recommendations to choose the right sized unit. If the engine compartment opens to an adjoining bilge or compartment, add its volume to the engine compartment’s volume prior to selecting a system.

Choose a size that meets or exceeds the requirements and if in doubt, go larger.

Installation

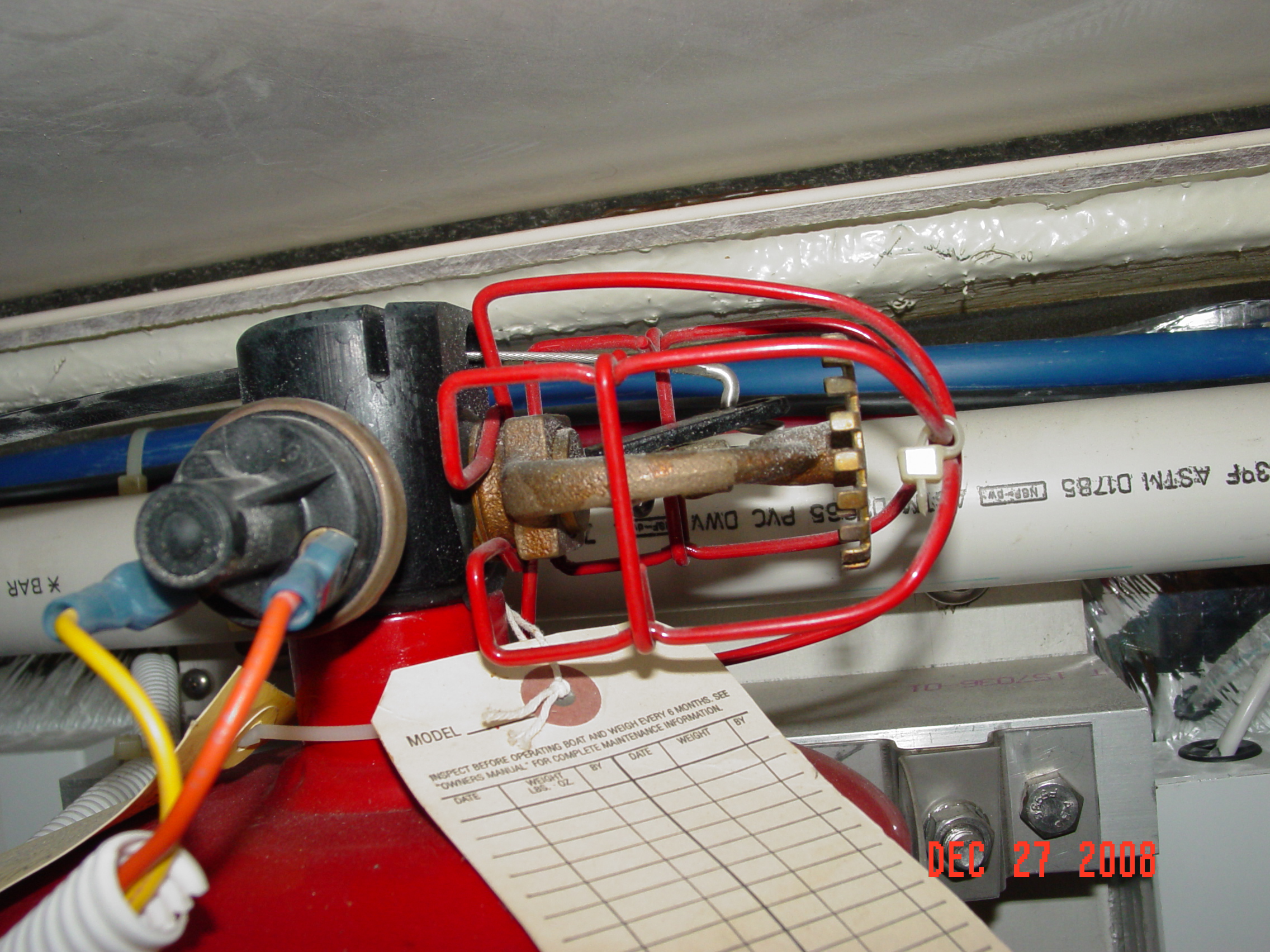

Cylinders for larger systems are typically mounted vertically on the forward or aft bulkhead, while the smaller cylinders for pre-engineered systems can be installed either vertically (with the sensor/discharge port up) or horizontally on an engine compartment bulkhead or overhead (depending on the unit).

While every fixed system installation must follow the specific manufacturer’s instructions, here are some general guidelines that can be applied to most any installation.

1. Install cylinders and controls so they are protected from weather and mechanical damage. Cylinders must be securely mounted and accessible for maintenance (i.e. removal for weighing, inspection, etc).

2. If mounting the cylinder on a bulkhead, locate it as high and close to centerline as possible, with the actuator pointing towards the opposite bulkhead or the engine. If mounted on the engine compartment overhead, the actuator should be in the center of the compartment with the cylinder parallel to the keel, the top facing the bow, and the actuator pointing down.

Having the unit centered and up high helps ensure the sensor will more readily detect a fire from all points of the compartment and quickly discharge, blanketing as much of the space as quickly as possible.

3. Don’t mount the unit on the underside of a hatch or access door (which could be blown off in the event of an explosion) and avoid locating sensors near engine exhaust manifolds, turbochargers or other engine components that could cause the unit to discharge due to radiated heat. The same holds true for mounting near engine compartment ventilation exhaust or intake vents, which could delay discharge by reducing temperature near the sensor.

A good pre-installation tip is mounting a thermometer in the engine room or compartment and measuring the temperature during normal operation. Engine room temps are typically around 130 degrees. A poorly ventilated or well insulated compartment can exceed the temperatures required to discharge the system, an issue you’ll want to address prior to installation.

4. Ensure the system is installed so that it doesn’t trap or rest in water (which could lead to corrosion).

5. Never combine the volume of two separate systems in attempts to protect a space. The problem here is that the two systems could discharge at different times, failing to blanket the compartment with a high enough concentration of extinguishing agent to put out the fire.

Fire!

Shut down the engine as soon as possible in the event of a fire. A running engine can pump fire suppressant out of the engine compartment, while continuing to suck in fresh air. Most automatic units have an option for installing an automatic engine shutdown, another excellent idea and one typically required in the case of diesel engines.

Many automatic units also have the ability to shutdown additional equipment, such as generators or exhaust fans (to prevent venting of the extinguishing agent from the space). If your engine utilizes a mechanical shutdown (air or fuel starvation) you’ll have to discuss the options for converting it to an electrical shutdown system with the manufacturer.

As a clean agent unit kills the fire without damaging the engine and components, boaters can often restart their engines after locating and correcting the initial cause and return to port under their own power. Make sure you have the ability to bypass the shutdown systems in order to bring the engine back up once the source of the fire has been determined and corrected.

By Capt. Frank Lanier

Captain Frank Lanier is a SAMS® Accredited Marine Surveyor with more than 40 years of experience in the marine and diving industry. He’s also an author, public speaker, and multiple award-winning journalist whose articles on seamanship, marine electronics, vessel maintenance and consumer reports appear regularly in numerous marine publications worldwide. He can be reached via his website at www.captfklanier.com