Making the Right Diesel-Engine Choice for Passage Making

A “passage maker” power vessel was defined by Robert Beebe (a retired U.S. Navy captain) in the 1950s in his book, Voyaging Under Power, as a “motor boat that can make an open ocean passage sufficient to at least cross the smallest ocean, the Atlantic.” The shortest route across is from Bermuda to the Azores; a distance of about 1850 nautical miles. A safety factor in excess of at least 10% (some prefer a 20% factor for long passages) should also be included. This in effect defines a passage-making power vessel having a range of at least 2050 to 2250 nautical miles at a realistic speed through the water.

The cruising speed of any power boat dramatically affects its fuel consumption which in turn dictates the quantity of fuel it must carry to safely make a passage. The theoretical cruising speed of a power vessel, whether displacement, semi-displacement or planing, is dependent on its water line length. That speed will not be in excess of one calculated by the formula speed in knots equals 1.34 multiplied by the square root of the water line length in feet.

In this article, we’re going to look at the right diesel engine for efficiently and safely completing the voyage.

Engine Choice

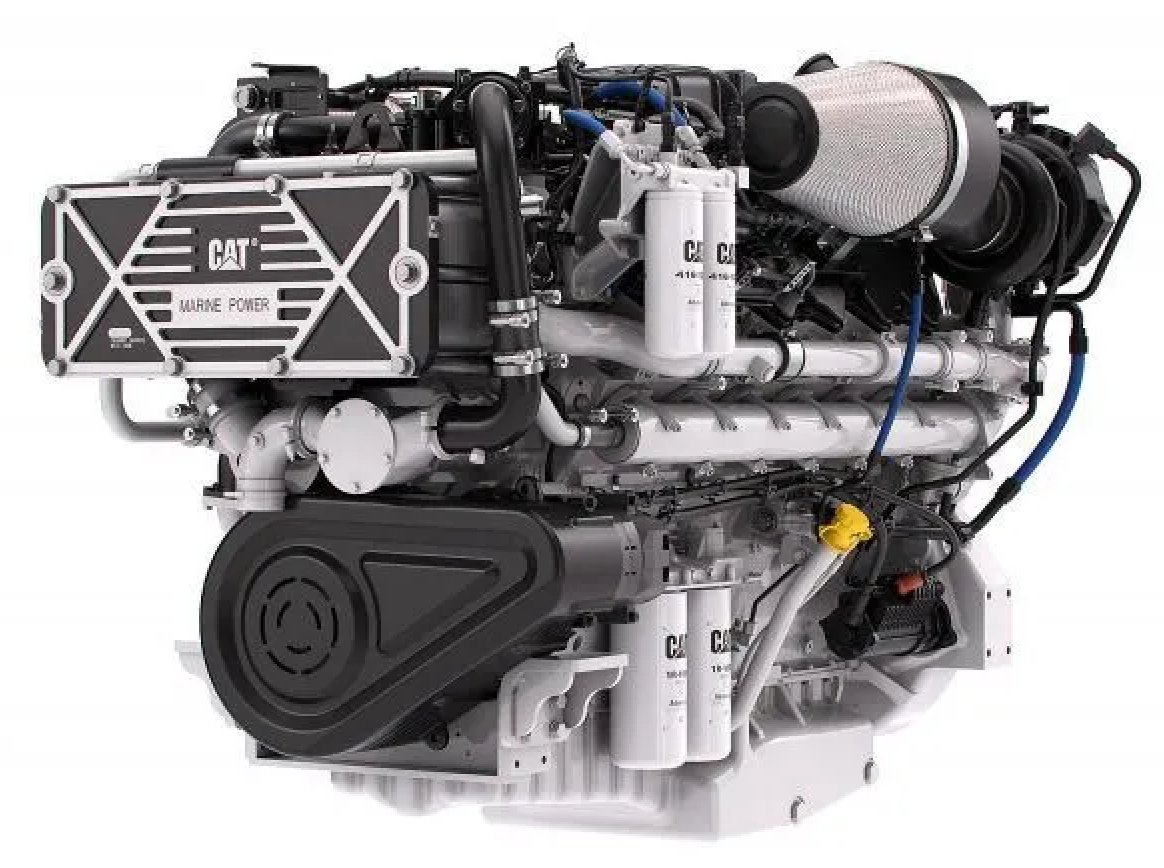

Marine diesel engines come in many design configurations, displacements, cylinder numbers, gearbox ratios, cooling arrangements, turbocharged or naturally aspirated etc. By its definition, a passage maker will be running at a reasonably high engine load for a considerable time period with no stops or breaks for possibly weeks on end. Reliability becomes a key factor in an engine choice.

Engine manufacturers sell horsepower and their engines can be rated at a wide range of available power and rpm. There is a great difference between a pleasure launch that might do 100 hours per year and a deep-water trawler that spends 4- plus weeks at sea per year.

But isn’t 400 hp for the pleasure boat is the same as 400 hp for the trawler? Yes, the power required to push the boats is the same, but the same engine is not suitable for both vessels. Simply put, the less horsepower extracted from a given weight of cast-iron engine, the longer it will live before a major overhaul.

Power Ratings by Usage

MTU manufactures marine engines from less than 100 hp to in excess of 2400 hp used in all kinds of vessels from pleasure boats to tugs and ships. When asked how many hours owners expected from their engines prior to a major overhaul, the company uses the following guidelines:

- Marine Maximum 3,000 to 5,000 hours

- Marine Intermittent-Maximum 8,000 hours

- Marine Intermittent 10,000 to 12,000 hours

- Marine Continuous 15,000 to 25,000 plus hours

To make their engines last these hours, the four power ratings as defined by Detroit Diesel Corporation/MTU were as follows:

Marine Maximum: This applies to high-performance vessels where speed is of primary importance and overall load factors are low. Normal or continuous cruising rpm should be limited to 90% of rated engine rpm and the use of full rated power should be limited to 10% (average) of operating time. This rating is normally for privately owned vessels with an average annual hour accumulation of less than 500 hours.

Marine Intermittent-Maximum: This rating is for privately owned vessels with long-range cruising capability and/or seasonal charter operation. Normal or continuous cruising rpm should be no more than 90% of the rated engine rpm and the use of full rated power should be limited to 10% (average) of operating time. All boats in this category are limited to a maximum of 1,000 hours per year.

Marine Intermittent: This rating applies to medium-to-high-speed commercial boats that operate at moderate-to-low load factors. These are boats intended for commercial service where 3,000 hours or less are accumulated annually. Normal or continuous cruising rpm should be limited to 95% of rated rpm with intermittent use of rated power permitted. Typical examples include crewboats, water taxis, pilot boats, ferries, charter sportfisherman, and patrol boats.

Marine Continuous: This rating applies to medium or low speed boats (normally a displacement design) that operate up to 24 hours per day, 365 days a year at high load factors. Typical examples include tugs and deep water trawlers. An example of a Detroit Diesel 6V92TA model and its different ratings were:

- Marine Maximum 550 bhp at 2300 rpm

- Marine Intermittent-Maximum 475 bhp at 2300 rpm

- Marine Intermittent 355 bhp at 2100 rpm

- Marine Continuous 270 bhp at 1800 rpm

From the figure above you can see that the continuous rating is less than 50% of the maximum pleasure craft rating. All engine manufacturers rate their diesels on a similar basis to ensure that they are correctly matched to the work they are expected to perform. When they leave a manufacturer they don’t know whether they will be working in a tug on the equator or in the cold of Alaska.

The Continuous Choice

Our passage maker will more than likely require an engine rating covered by Marine Intermittent or Marine Continuous (Caterpillar has similar definitions but define them as A for pleasure rating through to E for continuous rating) because it could be running a relatively high loading for 1,000 to 3,000 hours annually, depending on the mileages to be covered.

Now we have established the correct engine rating for a passage maker lets consider the accessories that increase an engine’s reliability. On a passage of 2,000 nautical miles at an average speed of 8.5 knots the engine will be expected to run for at least 235 hours. Most engine suppliers specify an oil and oil filter change at around 250 hours so an oil/filter change would not need to be undertaken on this passage.

For longer passages, it would be prudent to specify a larger capacity oil sump where the oil/filter change could be extended out to 500 hours or a bypass filter added to the lubrication system that allows extended oil-change periods based on oil periodic sampling. The ability to check an engine’s oil level via a “Murphy style level indicator”, while the engine is running is an added bonus. Sometimes an engine will not restart due to a starter or electrical fault after a shutdown at sea. Drifting without power in a seaway is not a pleasant experience.

Fuel Filters

The same goes for fuel filters. On a passage, a blocked or restricted fuel filter will force an engine shutdown to clean or replace the filter, unless the engine has been supplied with duplex style primary water separator/fuel filters and secondary fuel filters. These let the operator shut off and change a filter while underway. They are particularly useful if contaminated fuel is encountered on a voyage.

Salt-water impellers fitted to the cooling system are another weakness in a marine engine because they have a finite life span. Many passage makers specify a keel cooling system for the main engines. This eliminates the impeller altogether.

Naturally Aspirated or Turbocharged; Mechanical or Electronic

Over the years, cruisers with power vessels would say that only naturally aspirated diesel engines should be fitted to a true passage maker. This was due to the belief that a naturally aspirated engine was of a simpler design than a turbocharged engine and therefore more reliable. In reality turbocharged diesel engines have proven to be equally as reliable (provided oil and oil filters are regularly serviced) and offer at least 8% better fuel economy over a naturally aspirated engine.

With the cost of diesel continuing to increase, fuel economy becomes more important and this leads us into the question of whether electronic controlled engines are suitable for passage making?

Reliability and simplicity have been the key words of cruising yachtsmen the world over. Engines that are uncomplicated and easy to work on by owners or crew who are not marine engineers have always been in demand. Due to environmental regulations in the USA and Europe and the rising costs of fuel, nearly all new marine engines today are turbocharged, inter-cooled and have computer controlled governing and fuel injection systems. To the layman these engines have their place in trucks and machinery where a mechanic or technician can easily analyze and fix a problem, but at sea where support is non-existent, they can be perceived to be a liability.

If a fault alarm sound up and the engine shuts down, there is often no way of getting it to restart. With the older style mechanical engines a fix could often be made from spare parts on board and the engine started again. Normal reasons for a stoppage were fuel or overheating orientated or a simple electrical connection that could easily be over ridden by a person with a reasonable engineering/electrical knowledge.

On newer electronic engines, repairs are just not possible and expensive circuit boards/computers are just not feasible to carry as spares, let alone the computers often needed to re-program or override any fault settings that have come up. With electronic diesel engines, minor issues can be resolved by satellite telephone conversations with the engine dealers. They, like most new pieces of technology, have to be understood and as time goes by will become as reliable as the older style mechanical engines.

Make the Right Choice

To sum up, a diesel engine installed in a passage maker should be commercially rated, equipped with duplex fuel filters, capable of extended oil change periods, have a low specific fuel consumption for economy and have service/technical support available on a worldwide basis.

No particular engine supplier is better than the others, so let your personal preferences prevail in your selection of a suitable propulsion unit. Happy passage making.