Marlec’s Zipped Solar Panels

UK-based Marlec has developed a semi-flexible solar panel that has a sewn in zip, allowing it to be more easily attached to a bimini or spray hood.

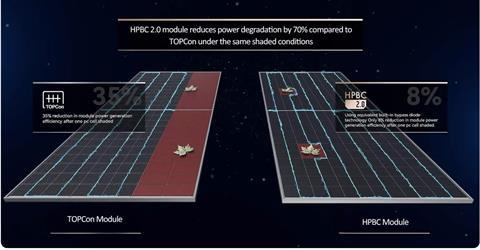

Renewable energy specialists Marlec Engineering Co Ltd have been busy introducing a new range of solar panels into their portfolio, taking full advantage of the more efficient HPBC cells made by LONGi. Hybrid Passivated Back Contact (HPBC) technology moves all the metal contacts to the back of the cell, making them less prone to the effects of shading and boosting efficiency. One range is flexible, and the other a rigid glass-coated design.

At the same time, the company has launched a Spectra Zipper panel with a large marine-grade zip physically stitched through the thin, semi-flexible skin. This is to allow easy deployment on any exterior fabric area of a boat. The other part of the zip remains permanently attached to the fabric, and once the panel has been zipped into place, a simple 2-core cable leading from the junction box is plugged into a nearby socket.

The 100W panel can be attached horizontally to biminis and spray canopies, with equally easy detachment for removal and storage (especially iof youremember to lubricate the teeth). Zips can also be sewn into dodgers and sail covers to facilitate vertical mounting for greater efficiency in high latitudes. The junction box has also been modified by a penetrative fixing to the panel, rather than the more usual route of a strong adhesive.

“When placed on a deck, this type of flexible panel often gets kicked,” said sales manager Stuart James. “The stronger attachment makes it more difficult to dislodge the junction box and the whole panel becomes more robust.”

James added that Marlec has seen a big uptick in the capacity of panels being placed on board, with some OEM customers fitting 400W panels as standard. This is helping to meet the growing demand for renewable energy om board. At the same time, panel efficiency continues to improve, with the new Longi panels significantly reducing the surface area required for the same output.

“Increasingly, the panels have better shadow protection from the HPBC technology,” James said. “They are wired so shaded areas are bypassed, rather than the whole panel losing efficiency when just one or two cells are in shade.”

The Spectra ZipperFlex panels were launched this year, and the two new Longi-equipped HPBC panel ranges will be available early in 2026.