Mercury Prop Performance Vent System (PVS)

The Performance Vent System, designed and patented by Mercury Marine, is a management system for the exhaust gases that exit from the propeller's hub. It lets a user control the venting of the propeller blades to optimize the acceleration for quick planing.

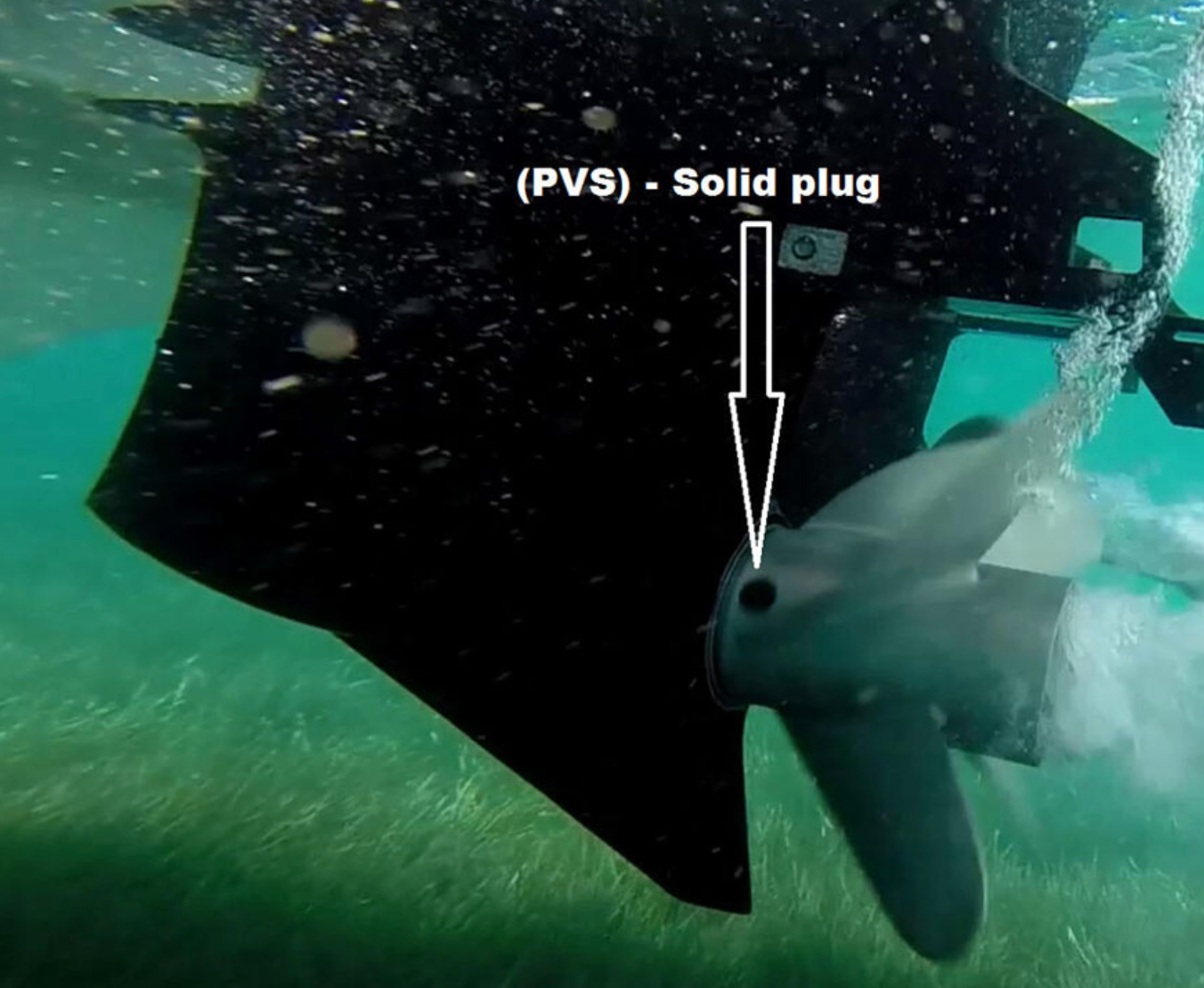

The system consists of one or two holes in the hub behind each blade through which the exhaust gases are driven between the propeller blades. Each hole has the same diameter of about .79” (2 cm), but it can be partially or fully closed with plugs provided by Mercury. Four sizes of plugs are available, 7mm (.28”), 9mm (.35”), 12mm (.47”) and one that completely closes the hole. This gives users the control they need to ensure the exact amount of venting needed.

How PVS Works

As the boat accelerates, some exhaust gases exiting the propeller’s hub “escape” through the vent holes and is driven between its blades. The direct consequence is the aeration of the water between the propeller blades. This means the water becomes “lighter” and the load applied to the propeller is reduced. The propeller can slip notably allowing the engine rpm to increase rapidly until the propeller bites, leading to quicker acceleration and shorter time to plane.

So the role of PVS is to let the engine to increase rpm more quickly. It reduces the time it takes for the engine to reach that level of rpm where the torque is as high as required to overcome the resistance against the boat getting on plane. As a result, planing time is reduced.

It should be made clear that the venting system is effective only during acceleration. Once the boat is up and running, it makes no difference to the rpm, performance or top speed. When the boat is running, the water that flows over the propeller-vent holes prevents the exhaust gasses from exiting the holes. In a way, it blocks the holes because the water pressure becomes much higher than that of the exhaust gases so the prop blades operate in solid, non-aerated water.

Vented or Non-Vented, and if Vented How Much?

Vented or Non-Vented and if Vented How Much?

When our propeller is not lagging during acceleration, there’s no reason to vent the prop. On the other hand, if it’s difficult to get the boat on plane, venting can create a significant improvement in planing time by leading the exhaust gases between the propeller’s blades. This lets the propeller operate in a “lighter” environment, reducing the load and causing the engine to over-rev. Some situations where venting could be useful include a heavy load, a higher-pitch prop or when an engine doesn’t make peak power at lower rpm.

But how can we know the percentage of ventilation needed for our propeller so it’s not excessive and won’t cause over-ventilating that leads to a loss of bite?

There is a simple way to determine the necessary amount of venting and it requires on-water testing. Place Mercury’s solid plugs in the holes in the propeller hub. Drill a .28” (7 mm) hole in the plug's center and head out for a test. If the boat doesn’t have a good holeshot or feels like a car in third gear, additional venting is needed. Widen the holes to .35” (9 mm) and test again to see the effects. If the acceleration still feels sluggish, drill a .47” (12 mm) hole.

Conversely, if the engine is over-revving and the prop doesn’t “hook up,” this means the water” is getting too aerated and smaller diameter plugs are needed. This way, a boater can find the “sweet spot” that delivers the best results for a given application and order the proper diameter plugs from Mercury.