Nature-Inspired Prop Improves Efficiency

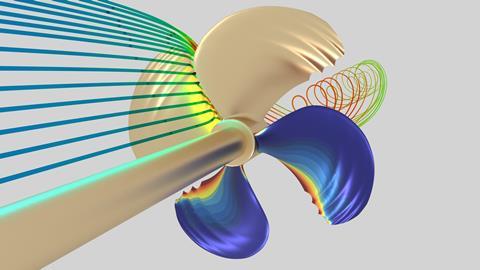

By adding ‘dorsal fin’ grooves to a propeller blade, UK-based CJR Propulsion enable gains of up to 13% efficiency when the prop is part of a flow-aligned package.

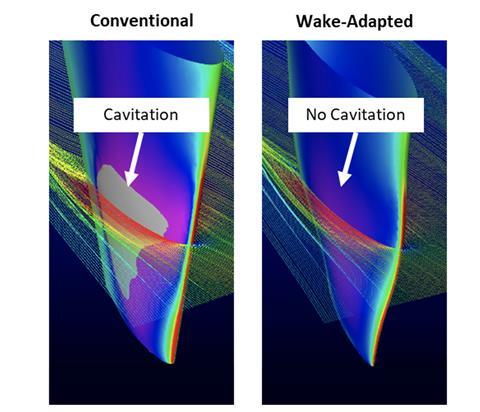

CJR Propulsion has long been a pioneer of using computational fluid dynamics (CFD) to calculate the most efficient design for all types of sterngear. The company explores every aspect of the underwater drive line, from the propeller boss to the P-brackets, and is also a champion of the wake-adapted rudder. The company believes in harnessing otherwise wasted energy in the turbulence to help improve fuel efficiency, and the new propeller is based on the design of the fastest fish in the ocean, the Sailfish. The company says the new blade shape can help increase efficiency by up to 13% when supplied as part of a complete CJR Propulsion flow-aligned sterngear package. (This figure is based on comparison to standard sterngear and hand-finished propellers).

“We’re excited to launch our latest propeller design,” said Alex Stevens, Technical Sales Director at CJR Propulsion. “The Sailfish is proven to be between 1.5% to 3% more efficient than our existing highly efficient CNC-machined versions. These include the Class S MRK Revolution, Billfish, and MRKSuperprop propellers. Using the science of biomimicry, we’ve designed the CJR Sailfish with a unique, undulated finish. This controls vortices by directing the water leaving the trailing edge and reducing tip vortex losses. The improved efficiency means lower fuel consumption and faster speeds for a given torque – maximizing the engine’s power. Reducing the thickness of the trailing edge also eliminates ‘singing’ and minimises vibration without the need for an ‘anti-singing’ edge.”

Stevens emphasizes that the efficiency gain from the new blade can be further enhanced by combining the Sailfish with other types of sterngear, creating an optimized underwater package. Minimizing resistance and harnessing the wake energy all help to boost fuel efficiency and range.

“Our CFD-modelled, fully CNC-machined Class S propellers, flow-aligned struts, and flow-aligned rudders typically deliver up to 10% efficiency gains compared to standard sterngear systems,” Stevens explained. “With the Sailfish, we can further enhance performance by up to 3% depending on vessel speed. For our customers, this can mean a significant reduction in fuel burn and fuel costs, a greater range, or an even faster top speed.”

Another advantage is that the new props can be retrofitted to legacy installations.

“Despite the unique look, these propellers are also a practical option,” Stevens said. “They can be retrofitted onto a standard shaft taper. The blades are also repairable – a key factor for many of our customers. And we can design and manufacture them up to 1500mm diameter and with any number of blades to suit a wide range of vessels and applications.”

According to CJR Propulsion, the efficiency gains delivered by the new propeller have been verified by Cape Horn Engineering. Further seatrials on a range of high-speed vessels are scheduled for early 2026. The Sailfish is said to be suitable for use on most vessels, from sportfishing and motoryachts to workboats and patrol vessels. It can be paired with a range of engines, including diesel, hydrogen, and electric to deliver optimum performance.

“CJR is committed to constantly innovating to find new solutions for our customers to help their projects succeed,” Stevens concluded. “Efficient technologies like foiling are becoming mainstream and the need to improve sustainability continues to increase across the marine industry. We’re proud to play a role in developing exciting, ultra-efficient performance products to support our industry to thrive.”