Navigating the Build Process - Part 3

The Weber Marine Elite 22m Flybridge Motoryacht

Pacific PowerBoat Magazine is excited to continue our series on the build process of the Bill Upfold-designed Elite 22M Flybridge Motor Yacht. Currently under construction at Weber Marine in Gulf Harbour, Auckland, this journey takes us from initial concept discussions with the owner to its on-water launch and culminates in a detailed review scheduled for late 2026.

This 22-meter masterpiece combines cutting-edge engineering with bespoke luxury. Constructed using epoxy resin, E-glass, and a PVC foam core over a male mold, the yacht promises to be both weight conservative and robust.

The design includes four staterooms:

- A full-beam master suite amidships.

- A VIP stateroom forward.

- Two twin guest cabins, all featuring ensuite bathrooms.

Part Three – Hull Construction is well into production, and the deck is underway

Hull Progress:

With the hull still upside down, the foam core was vacuum bonded to the inside skin, and the exterior fiberglass laminate was applied. Once filled and faired, it was time to add the planning strakes, keel, and bow thruster tunnel to the underwater section.

The scaffolding surrounding the hull was removed, and the frames were sheathed using 12mm MDF and Teflon film, creating the plug surface.

The hull then received an inside skin before having the PVC foam core vacuum bonded (including the window rebates).

Deck Underway:

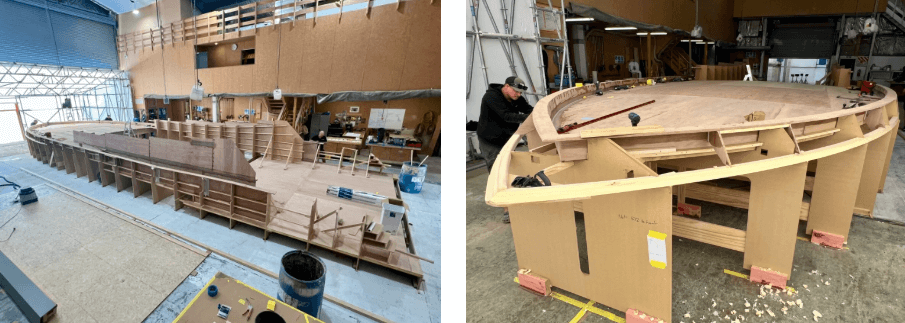

Meanwhile, while hull construction continues, the team in another of Weber Marine’s Gulf Harbour Marina sheds has begun work on the deck.

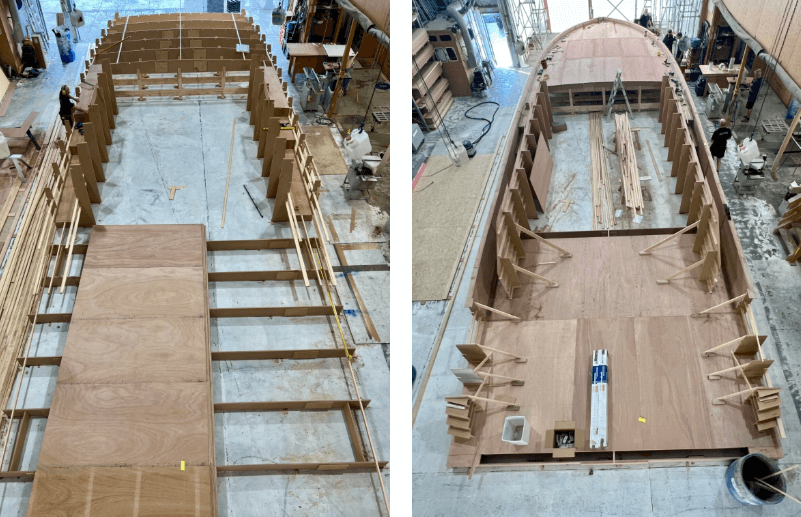

As with the hull, the first step was to stand the CNC cut frames, which were then sheathed with 6mm ply. This will create the inside skin of the deck.

The 6mm ply is then covered in fiberglass and, like the hull, reinforced in high-stress areas (e.g., cleat fixings). The now-fibreglassed 6mm ply is next covered with PVC foam core and resin-vacuumed to ensure even resin distribution and eliminate air entrapment.

Other Arrangements and Build Requirements:

While these two large components (hull and deck) are in progress, a number of decisions and orders must be made to keep the build process moving smoothly. These include selecting and ordering significant components, including the Kohler genset, Humphree stabilizers, twin MAN 1550HP V12 engines, and Twin Disc gearboxes with EJS joystick controls.

Stay tuned as we continue to follow this innovative build and provide updates on the progress of this exceptional vessel.