Nonskid Deck Renewal Options

There’s nothing more hazardous than safety equipment that seems functional, but in reality they fail when needed the most. A perfect example of this is worn nonskid that provides adequate footing when dry, but becomes dangerously slippery during wet or stormy conditions. Here’s a quick look at some popular nonskid renewal choices.

Non Skid Options

When the factory-molded nonskid of a typical fiberglass boat becomes worn, owners have a number of aftermarket options to choose from, each with pros and cons to weigh in addition to their actual nonskid qualities. Considerations such as cost and durability are certainly important, but so too are factors like ease of installation or cleaning when exposed to contaminants such as dirt or fish slime. The ultimate goal is a nonskid surface that not only meets these concerns, but is also effective in extreme conditions while providing a good feel underfoot.

The most common nonskid replacement options can be loosely divided into three categories: deck paints with a grit type traction material added to them, deck paints featuring a textured surface and nonskid matts or coverings that rely on some form of adhesive to mount them into place.

When the factory-molded nonskid of a typical fiberglass boat becomes worn, owners have a number of aftermarket options to choose from, each with pros and cons to weigh in addition to their actual nonskid qualities. Considerations such as cost and durability are certainly important, but so too are factors like ease of installation or cleaning when exposed to contaminants such as dirt or fish slime.

The ultimate goal is a nonskid surface that not only meets these concerns, but is also effective in extreme conditions while providing a good feel underfoot - and bottom.

The most common nonskid replacement options can be loosely divided into three categories:

- deck paints with a grit type traction material added to them,

- deck paints featuring a textured surface and nonskid matts or

- coverings that rely on some form of adhesive to mount them into place.

Deck Paints - Grit Type Non-skid

These are deck paints that use some form of “grit” or media to provide traction. Examples include anything from graded/sifted sand or crushed walnut shells to polymer beads. Larger, sharper grit produces the best traction, but is also less friendly to bare feet, bottoms in a bathing suit, or bare skin. Conversely, fine grit is less aggressive to skin, but provides less traction.

Other considerations include the use of one or two-part paints (the former being cheaper, the latter being more durable) and color selection. Lighter colors are cooler, but produce more glare and tend to show dirt more readily.

Depending on the product used, the grit itself can come premixed in nonskid paint or be sold as an additive for mixing into deck paint by the user prior to application.

It can also be sprinkled onto wet deck paint, followed by additional coats of thinned paint (to provide the appropriate color).

Products such as Durabak, Epifanes Nonskid Deck coating, Interlux Interdeck and Pettit EZ-Decks are all good examples of premixed nonskid paint.

Modern nonskid additives include Awlgrip Griptex (a polymer bead aggregate that comes in fine, coarse, and extra coarse grades) and Epifanes Non-Skid Beads, a pre-measured polymer-bead compound sold for mixing with Epifanes polyurethane and monourethane paints.

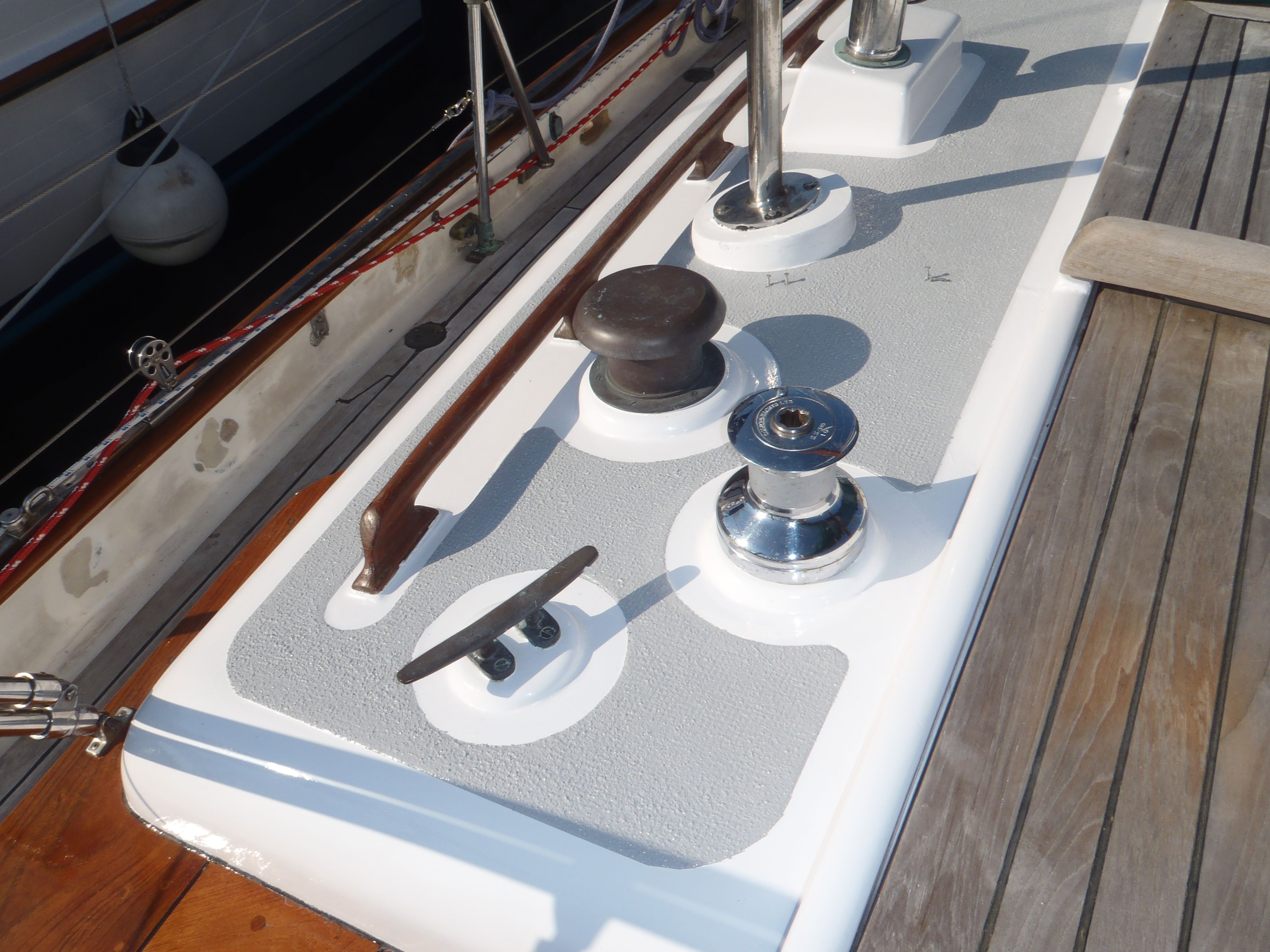

Textured Deck Paints

Textured deck paints get their traction from the raised patterns created by using a special roller sleeve during application. As the nonskid property is provided by the texture of the paint itself (rather than suspended grit or other filler media) there’s no worry about the paint wearing down over time and releasing the nonskid material. However, over time the paint itself will wear down.

The texture of the paint using this method is self-evident to the trained eye. If this method is chosen, we recommend creating a sample on scrap plywood to get an idea of how the texture will look. The pattern on the rollers are not all the same, so investigate options before picking one.

Nonskid Matts and Coverings

Nonskid matts and coverings are a popular choice due to their traction, stain resistance, low maintenance, and wide variety of colors and finishes (including faux teak) - and comfortable feel on feet, bottoms and bare skin anywhere on the body. Their cushiony nature provides a modem of shock absorption (increasing comfort underfoot) and noise reduction. Their ease of installation lets even the DIYer achieve a custom look, whether installing smaller self-trimmed matts or template-made kits covering an entire deck.

Popular examples include Treadmaster, SeaDek, and Esthec Nautical decking.

Treadmaster and Esthec panels are glued in place using a manufacturer supplied, user applied adhesive. SeaDek utilizes marine grade 3M™ pressure sensitive adhesive backing, allowing you to simply peel and stick panels in place.

Cost-wise, nonskid matts and deck coverings will typically be more expensive than paints, but they also provide more customization with regards to design patterns and color options.

Basic Installation Tips

While these will vary widely depending on which nonskid you choose, here are some basic tips that can be applied to most any nonskid installation.

1. Prep the Surface per the Manufacturer

If the deck has old, failing nonskid that is loose it will need to be removed first. If the existing nonskid is simply worn, the first step typically involves washing the deck with a mild boat soap to remove dirt, grease, and other contaminants.

Allow it to dry, then sand with an orbital sander using 60 grit paper to both level the area and scuff the old surface. Finish with 120-grit, vacuum up any dust, and wipe down the surface with a rag and 202 Fiberglass Solvent Wash, replacing the cloth as it picks up residue.

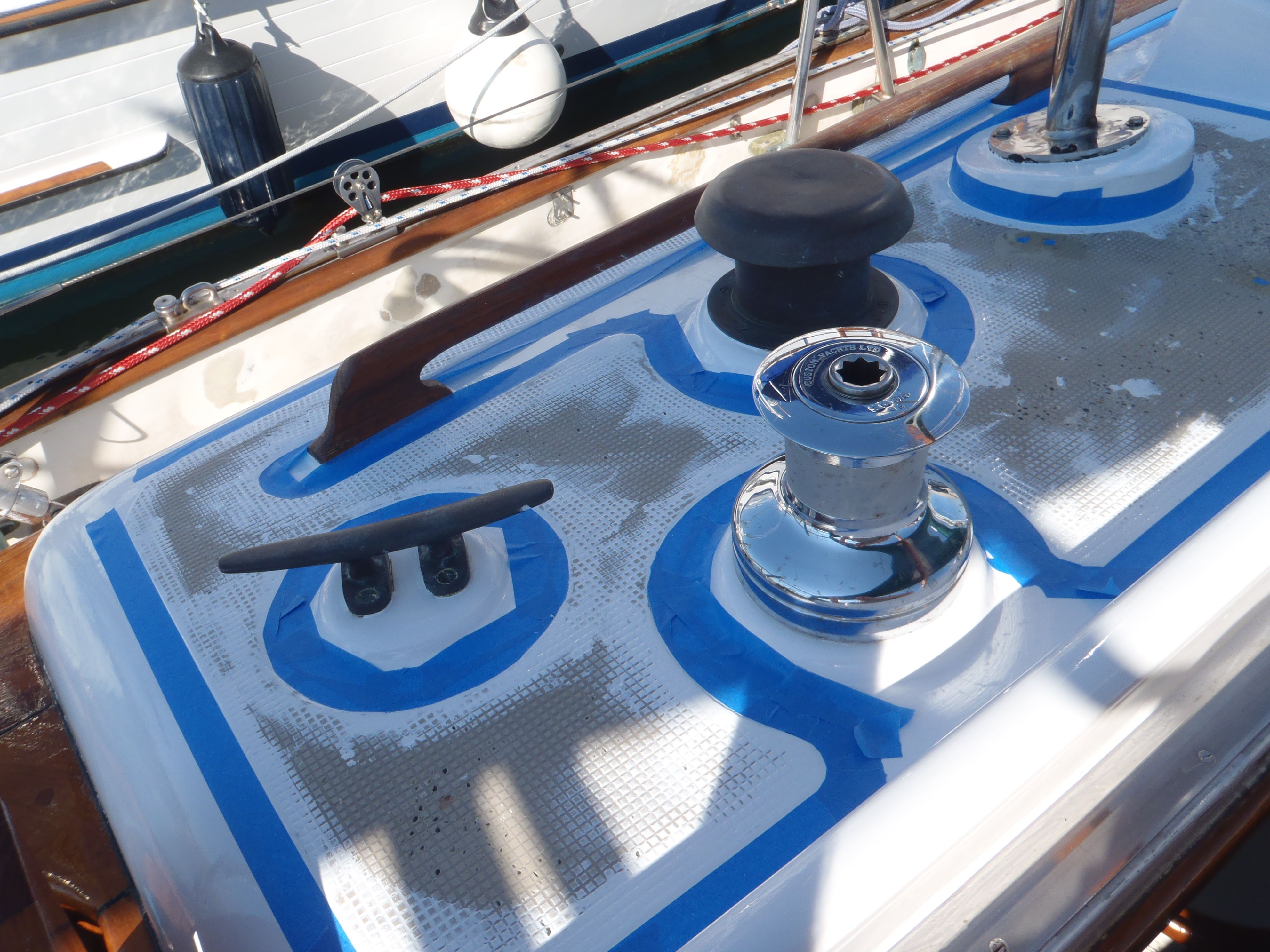

2. Good Taping Makes Good Results

With apologies to Robert Frost, careful masking (straight lines, curved corners, etc) when applying nonskid paint will help give your finished project a professional look. For cleaner edges, allow paint to set up for about 30 minutes before removing masking tape. Don’t wait until fully dry however, as the tape will be more difficult to remove and may “tear” the paint.

By Capt. Frank Lanier

Captain Frank Lanier is a SAMS® Accredited Marine Surveyor with more than 40 years of experience in the marine and diving industry. He’s also an author, public speaker, and multiple award-winning journalist whose articles on seamanship, marine electronics, vessel maintenance and consumer reports appear regularly in numerous marine publications worldwide. He can be reached via his website at www.captfklanier.com