A Plastic That’s Stronger than Steel?

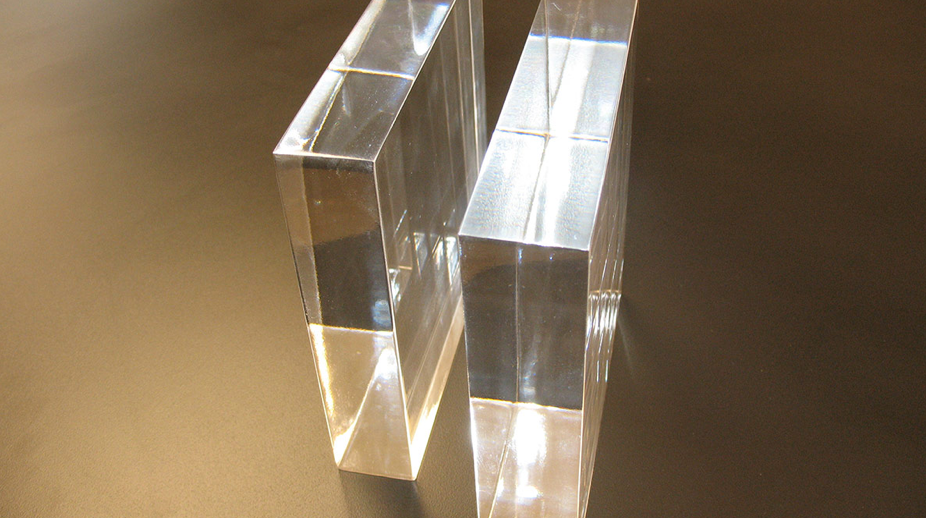

Using a novel polymerization process, MIT chemical engineers have created a new material that is stronger than steel and as light as plastic and can be easily manufactured in large quantities, according to an article last month in MIT News, which is run by the university.

The new material is a two-dimensional polymer that self-assembles into sheets, unlike all other polymers, which form one-dimensional, spaghetti-like chains. Until now, scientists had believed it was impossible to induce polymers to form 2D sheets.

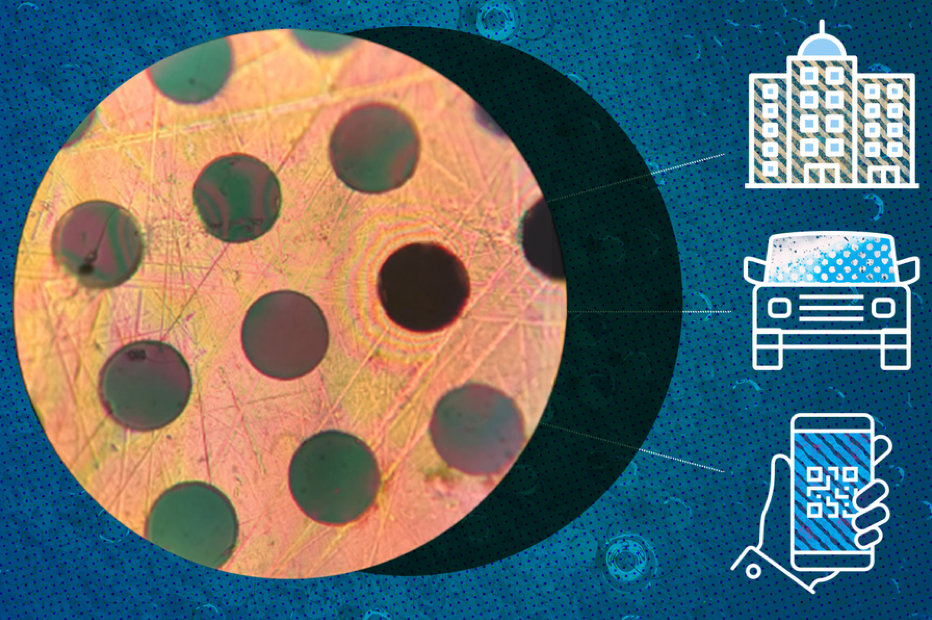

Coating has Unlimited Uses

Such a material could be used as a lightweight, durable coating for car parts or cell phones, or as a building material for bridges or other structures, says Michael Strano, the Carbon P. Dubbs Professor of Chemical Engineering at MIT and the senior author of the new study.

“We don’t usually think of plastics as being something that you could use to support a building, but with this material, you can enable new things,” he says. “It has very unusual properties and we’re very excited about that.”

Light but Strong

The researchers found that the new material’s elastic modulus — a measure of how much force it takes to deform a material — is between four and six times greater than that of bulletproof glass. They also found that its yield strength, or how much force it takes to break the material, is twice that of steel, even though the material has only about one-sixth the density of steel.

Numerous Applications

Matthew Tirrell, dean of the Pritzker School of Molecular Engineering at the University of Chicago, says that the new technique “embodies some very creative chemistry to make these bonded 2D polymers.”

“An important aspect of these new polymers is that they are readily processable in solution, which will facilitate numerous new applications where high strength to weight ratio is important, such as new composite or diffusion barrier materials,” says Tirrell, who was not involved in the study.

Impermeable to Gases

Another key feature of 2DPA-1 is that it is impermeable to gases. While other polymers are made from coiled chains with gaps that allow gases to seep through, the new material is made from monomers that lock together like LEGOs, and molecules cannot get between them.

“This could allow us to create ultrathin coatings that can completely prevent water or gases from getting through,” Strano says. “This kind of barrier coating could be used to protect metal in cars and other vehicles, or steel structures.”

Further Study

Strano and his students are now studying in more detail how this particular polymer is able to form 2D sheets, and they are experimenting with changing its molecular makeup to create other types of novel materials.

The research was funded by the Center for Enhanced Nanofluidic Transport (CENT) an Energy Frontier Research Center sponsored by the U.S. Department of Energy Office of Science, and the Army Research Laboratory.