Powerboat Props – The Basics

Options abound in powerboats – because the nature of the prop in the powerboat is to push a load (the boat) with speed, duration and direction. It requires some careful design to achieve these ends simultaneously – and engine manufacturers work hard to find the best balance. That said there are many ways to upgrade or to change the prop to achieve your own specific wants or needs.

Props for inboards stern-drives and outboards are available in aluminum, bronze, and stainless steel. They may be 2, 3, or 4 bladed (and some workboats have 5 and 6 bladed props).

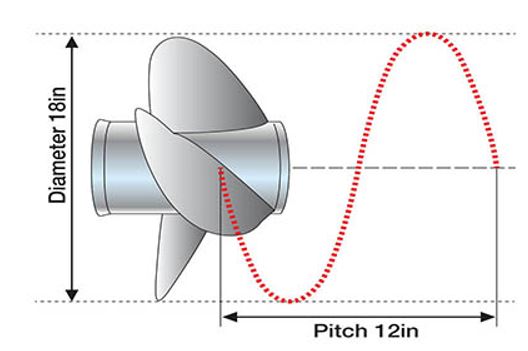

Props are designed with two dimensions: A diameter and a pitch. These are typically engraved on the body of the prop for reference. The diameter refers to the measurement from the tip of one blade, across to the arc of the opposing blade. The pitch refers to the distance forward that the boat is pushed in one revolution (a 21” pitch would move a boat 21” forward with every revolution).

These variables are probably the single most important elements to consider when looking to increase performance. At the same time, two user variables need to be considered: The speed that the boat is moving (Miles per Hour – MPH), and the engine speed (RPM – the engine revolutions per minute).

You would think that as the engine turns faster, the prop turns faster and therefore the boat moves faster – which is theoretically true – but these can be tuned by adjusting changing the prop to one with a different diameter and pitch.

Here's how it works:

Diameter usually increases for propeller used on slower boats and decreases for faster boats. Generally, this is pre-determined by engine manufacturers, based on the use of the boat, keeping in mind the engine horsepower that is being used. The pitch allows you to play with the variables of acceleration and top speed. A higher pitch will give a higher top speed, but slower acceleration.

A lower pitch gives quicker acceleration, but offers a lower top speed. Each inch of pitch is worth about 200 engine RPM’s – so moving from a 21” pitch to a 23” pitch will decrease the engine RPM’s by about 400.

The caveat, here, is that the engine is designed to run at a certain maximum (wide open throttle) RPM. If the prop pitch is too low, the engine may run beyond the desired RPM’s and damage can be caused. If the prop pitch is too high, the motor may run below the ideal wide-open throttle RPM’s, making it feel bogged or sluggish, and potentially causing engine damage.

The next piece of this puzzle is the determine the number of blades and the material:

3 vs 4 blades - in general, 3 blades allow a boat to go faster than 4 blades. 4 blades were introduced to allow for better handling at low speeds, and have since evolved to allow boats better fuel economy and low-speed planning ability. 4 blades are usually seen on larger boats and power cruisers, where 3 blades are found on go-fast runabouts. These can be interchanged to meet your performance goals.

Aluminum vs Steel - Aluminum is lighter and more cost effective. Steel is stronger but more expensive. In shallow waters, or in areas where there are underwater hazards, stainless steel props have been known to hold up better – but are more costly to replace if damaged.

Putting it all together:

When making changes by selecting a new prop, you’ll need a number of pieces of information: The boat type and typical use (including the hull shape and engine size), The current diameter and pitch of the propeller, the engine RPM’s at wide-open throttle (when loaded and trimmed appropriately).

Next – what are your performance goals: Acceleration or top-end speed?

Choose a prop (perhaps with the help of a your local marine chandlery) that will best suit your engine and performance goals (handling, fuel economy, resistance to damage, acceleration and top-end speed). Once you’ve determined the ideal material, number of blades, diameter and pitch requirements, you’re read to buy.

Modern props are purchased using 2-piece propellers, allowing them to be customizable. There are many permutations of diameter and pitch, and there are many engine types with different shaft sizes and spline configurations.

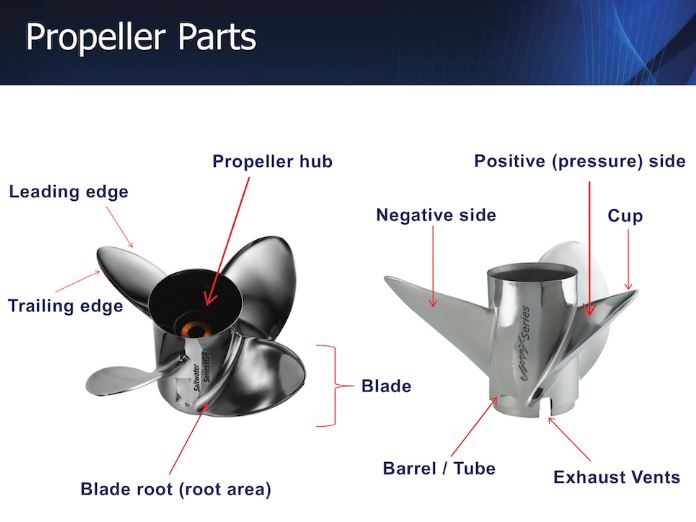

So, to make it simple, props are available in each diameter/pitch combination, and a hub (the inner core of the propeller) is purchased separately, to correspond with the engine type and spline configuration on your engine. Prop dealers typically have catalogues available to assist with the correct choice of prop and hub combination – when in doubt, ask!