Propeller Damage: Repair or Replace?

Propellers are a vital component of the marine driveline and the key ingredient when converting engine output torque into forward thrust. The importance of correct sizing and blade condition should not be underestimated for driveline efficiency and engine health.

When looking at a propeller, there are three basic aspects that affect performance; diameter, pitch and number of blades — these are usually expressed in the following format of imperial measurements; 11” x 15” (27.94 cm x 38.1 cm) 3B. This example would describe a propeller of 3 blades with 11” (27.94 cm) outside diameter and a theoretical pitch of 15” (38.1 cm), meaning if placed into a solid block of wood for example and turned one full rotation — it would move forward 15” (38.1 cm). This does not happen in the real world because of slip factor when operating in a liquid and trying to push a heavy hull, so it’s referred to as “theoretical” pitch.

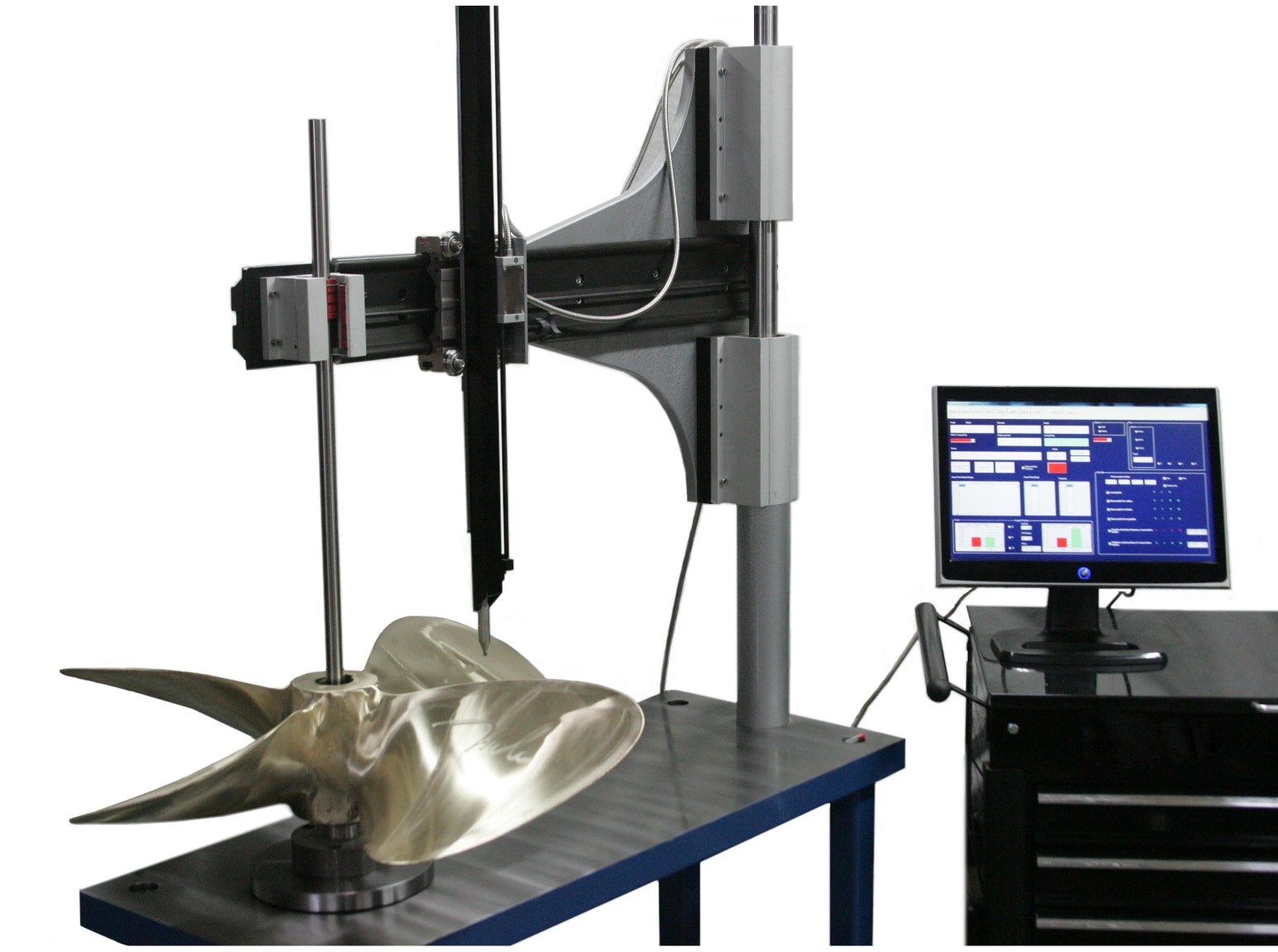

Propeller sizing, manufacture and repair have come a long way in the past 20 years, to the point that there is almost no “guess work” involved. Companies such as Hale Propeller now work with long proven mathematical calculations, Prop CAD software, decades of sea trial data and the latest scanning equipment. This provides detailed reports before and after the adjustments or repairs have been made.

This isn’t to say that the sizing strike rate is 100%, considering all the factors involved in a propeller calculation and the importance of accurate input data. However, by utilizing this knowledge and technology you increase the chance of maximizing performance and efficiency while avoiding additional haul outs, blade adjustments and fuel costs. These are the potentially costly hidden dangers of incorrect propeller sizing/ repair that can often sting boat owners who have been lured in with a hugely discounted price. The well-known proverb “the poor man pays twice” often applies in the propeller world.

Watch Out For the Bumps

With modern day GPS we are fortunate to be able to safely navigate the coastline, however, run-ins with a reef, rope, ramp or logs can and do occur. So, what to do when the unexpected happens and you’re left with a nasty vibration?

Firstly, do not attempt to straighten the propeller yourself; it may look better, but it is very unlikely the blade will be within the required tolerances. More importantly, when using incorrect equipment and techniques you run the risk of cracking a blade and or further damaging other driveline components. Significant bends are carefully straightened with heat applied within a strict temperate range.

The propeller should be removed and sent in for repair assessment. In our workshop this process can include; clean off, MRI Prop Scan, visual assessment and NDT dye penetrant crack testing. In cases of serious impact damage, the shaft and half coupling should also be properly assessed for damage as even the slightest bent shaft or coupling register runout can cause vibration and subsequently, damage to other driveline components.

Repair Or Replace

In our current throwaway society, many boat owners are quite receptive when presented with the option of propeller replacement when, in most cases (especially for bronze propellers), this should be a last resort that is often not necessary.

Propellers are an expensive part of a vessel and should have been custom designed and manufactured to suit the application. If looked after properly and protected from galvanic corrosion, they can, in some pleasurecraft applications be in use for longer than half a century. This is evident in commercial applications where a propeller may have more than 10 significant repairs over many thousands of running hours.

Propeller shops are often asked about the availability of second-hand propeller options — the reality is there are not many and it often means compromise or a long financial cluster. You will need to match; blade area, blade number, rotation, pitch, diameter, hub diameter, bore diameter, keyway, taper length and angle. These are all carefully considered when designing a custom-built propeller. You have a better chance with outboard or sterndrives but still the options are few and far between.

Experienced prop technicians tell us that aluminum and SS propellers can often be repaired to like-new condition. When researching repair facilities, ask what equipment they have and ask around. Word of mouth will usually lead back to the same place.

Using MRI Prop Scan technology, repair facilities take thousands of measurements to return a propeller blade to its original dimensions. These equipment reads blade pitch, cross section tolerance, among other expectations. Blade balance is also an important factor but accounts for significantly less of the experienced vibration than blade pitch tolerance. You should always request a copy of the before and after Prop Scan reports because it provides proof that the repair was carried out to the correct tolerances and gives an accurate record of the pitch measurement. It can vary up to 2” (5.08 cm) from the stamped size depending on the manufacturer.

Prop Reliability

The main factors affecting a propeller’s repairability are; galvanic corrosion/electrolysis, volume of blade material and of course the extent of the damage to begin with.

Galvanic corrosion occurs when dissimilar metals are placed in salt water, with the least noble becoming the sacrificial anode and more noble the protected cathode. It is the silent killer in the propeller world and can cause thousands of dollars in damage in a matter of weeks. A common cause of propeller corrosion is failing shaft bonding straps. The carbon brush type, if not properly cleaned and maintained can develop a film that breaks the circuit and isolates the driveline from the zinc.

So, what’s the big deal? Bronze affected by galvanic corrosion becomes brittle and prone to cracking. It is also difficult to weld to because the corroded parent material now differs in composition from the original material specification. Because insurance policies do not cover galvanic corrosion, even the slightest bent blade from impact can render the propeller a write-off at the owner’s expense. Understandably this news is not often well received.

Combating Galvanic Corrosion

How do we combat galvanic corrosion? Shaft- and transom-mounted anodes are the best solution because they can be easily checked, replaced and inspected. Threaded bullet anodes mounted aft of the propeller are preferred to the clamp style because they do not disrupt waterflow to the propeller. If shaft straps must be used, ensure that they are always bonded correctly and carefully maintained per the manufacturer’s instructions. Your propeller should be regularly checked for any pitting or discoloration.

Propellers are manufactured in three primary blade materials; bronze for larger vessels and stainless-steel and aluminum for smaller trailerable.

Bronze propellers are primarily custom made to order in nickel-bronze aluminum (better known as Nibral) and manganese bronze or Mag. Most older propellers are Mag with the preferred and superior casting material today being nibral for its higher tensile strength and corrosion-resistance. A bronze propeller in as new condition can be re-pitched up to 3” (7.62 cm). Cracks, bends and even missing blade tips can be repaired depending on blade thickness and material condition.

Stainless-steel propellers are mostly reserved for outboards and sterndrives for which they are mass produced. So, the availability of sizes off the shelf is good. Stainless steel is more difficult to repair than bronze but the high cost of replacement makes it worthwhile in most cases, especially for counter-rotating twin propeller applications. The blades are more difficult to adjust and usually 2” (5.08 cm) re-pitch is maximum. They are also more prone to cracking and sub-par crack repairs are common. Welding over the crack and grinding back is not good enough because it results in a thin, weak repair. Because of the higher operating speeds, it is especially important that the blades are repaired to within the correct ISO tolerances to ensure smooth running and prevent gearbox damage.

Aluminum propellers are best suited to lower horsepower outboard and sterndrive applications because of the softer material. They are not suitable for high-speed operation and the blades must be thicker than stainless steel. These are the cheapest option available (approx. half the cost of stainless steel) so are often not worth repairing. If looking at repair, check the rubber hub insert because if this is damaged or has spun then propeller replacement is the best option.

The Right Fit

Propeller fitment is the final piece of the propeller repair puzzle. For outboards, ensure that the spline is clean, then reapply an even coat of marine grease. Slide the thrust washer over the spline, then slide the propeller over the spline, washer, nut and finally either folding tab washer or split pin depending on the requirement. Always carefully check the tab washer or split pin if you are planning on reusing the old one because failure can result in a lost propeller.

With larger bronze propellers running on a shaft taper it is important to check the fit before installation. Many new inboard propellers are lapped to the driveshaft or if not available then to a matching mandrel to obtain a 100% fit. This is an important part of the build process because the friction of the two tapers locks the shaft and propeller together — not the key, which is just a backup. Some propellers and shafts run without keys.

Because of this, it is important to never grease or apply anti-seize to any driveline tapers, if a propeller or half coupling is difficult to remove it is usually a good sign that indicates good taper contact. When tightening the prop nut, take to not bend the blade tips. Lock the propeller in position with a wooden block either between the hull or ground as close to the blade root as possible — not at the tip. Finally, check your anodes.