Sharrow Prop Tested on Everglades 435

Sharrow propellers have proven their worth in single, dual and triple outboard installations—how do they fare in a quad 425 setup?

The Everglades 435 chosen for the comparison test is an upscale blue water CC with an LOA of 42' 8'' (13 m), a beam of 12’ (3.66 m) and a dry weight of 16,800 lbs (7,620 kg). Deadrise is 25 degrees, confirming her mission in offshore fishing.

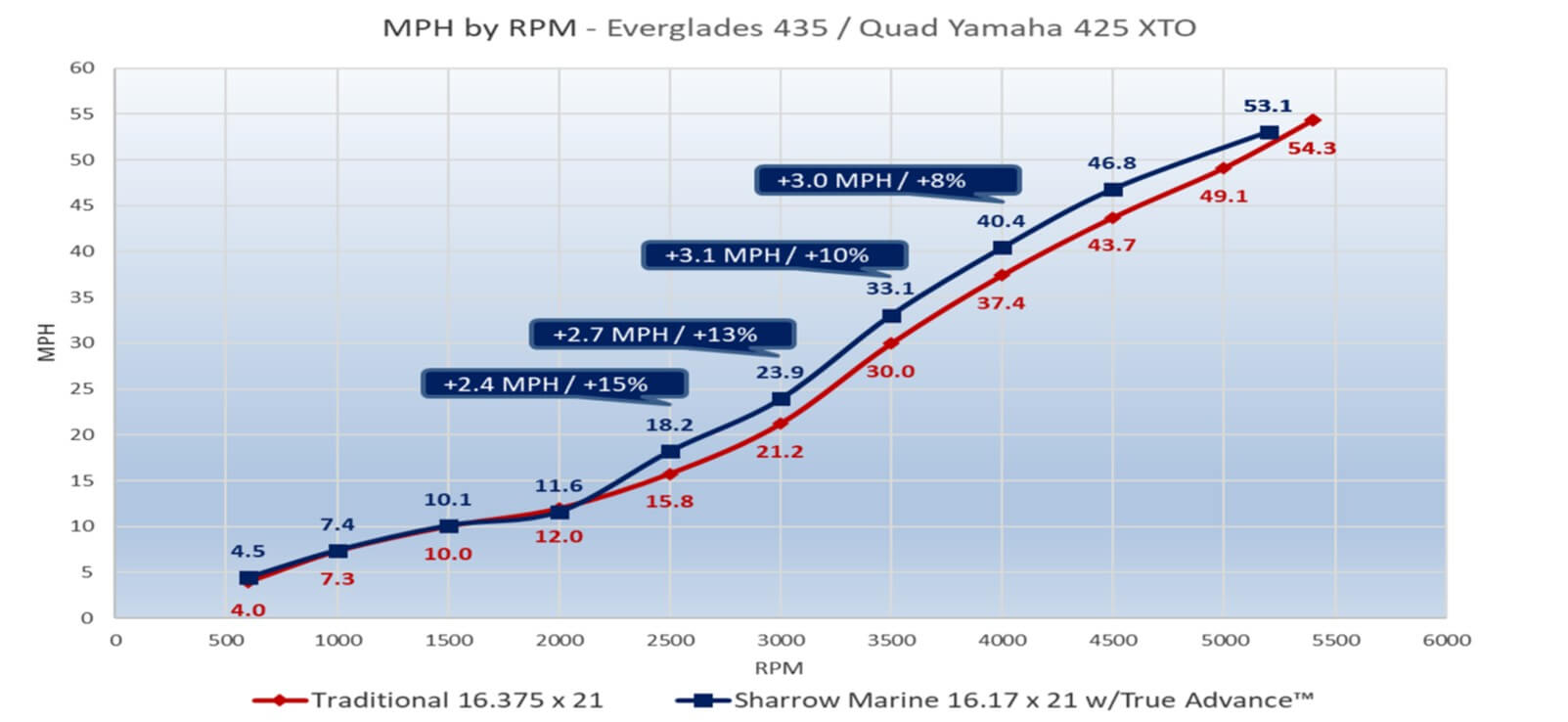

She was equipped with four Yamaha 425-hp XTO’s for the test conducted by Sharrow engineers. Stock propellers were three-blade 16.375 x 21 stainless steel.

Sharrow propellers selected for the comparison were True Advance 16.17 x 21 stainless. Greg Sharrow introduced the innovative propellers to the market in 2012, and has since developed phenomenal growth in the company, including cooperative production deals with Yamaha and with VEEM.

Machined Continuous-Blade Propellers

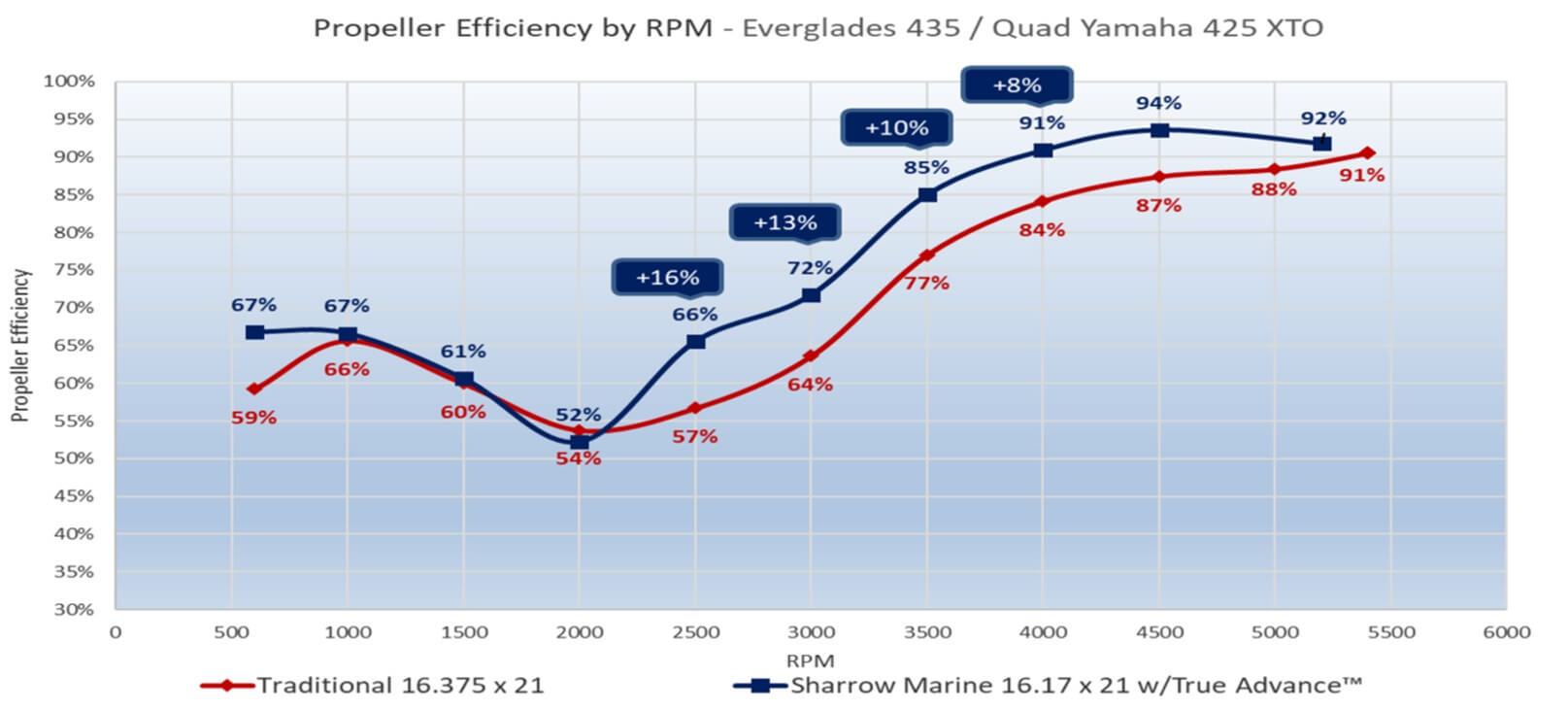

Sharrow propellers are CNC machined in a continuous blade design which has proven to make them more fuel efficient than conventional propellers in nearly every head-to-head test, particularly in mid-range operation.

Users also report more positive control at low rpm around the docks, and overall lower vibration and noise.

While Sharrow Propellers are significantly higher priced than conventional designs due to the extensive machining and exact tolerances, heavy users like charter boat operators say they pay for themselves in fuel savings in a few seasons.

Improved Range and Economy

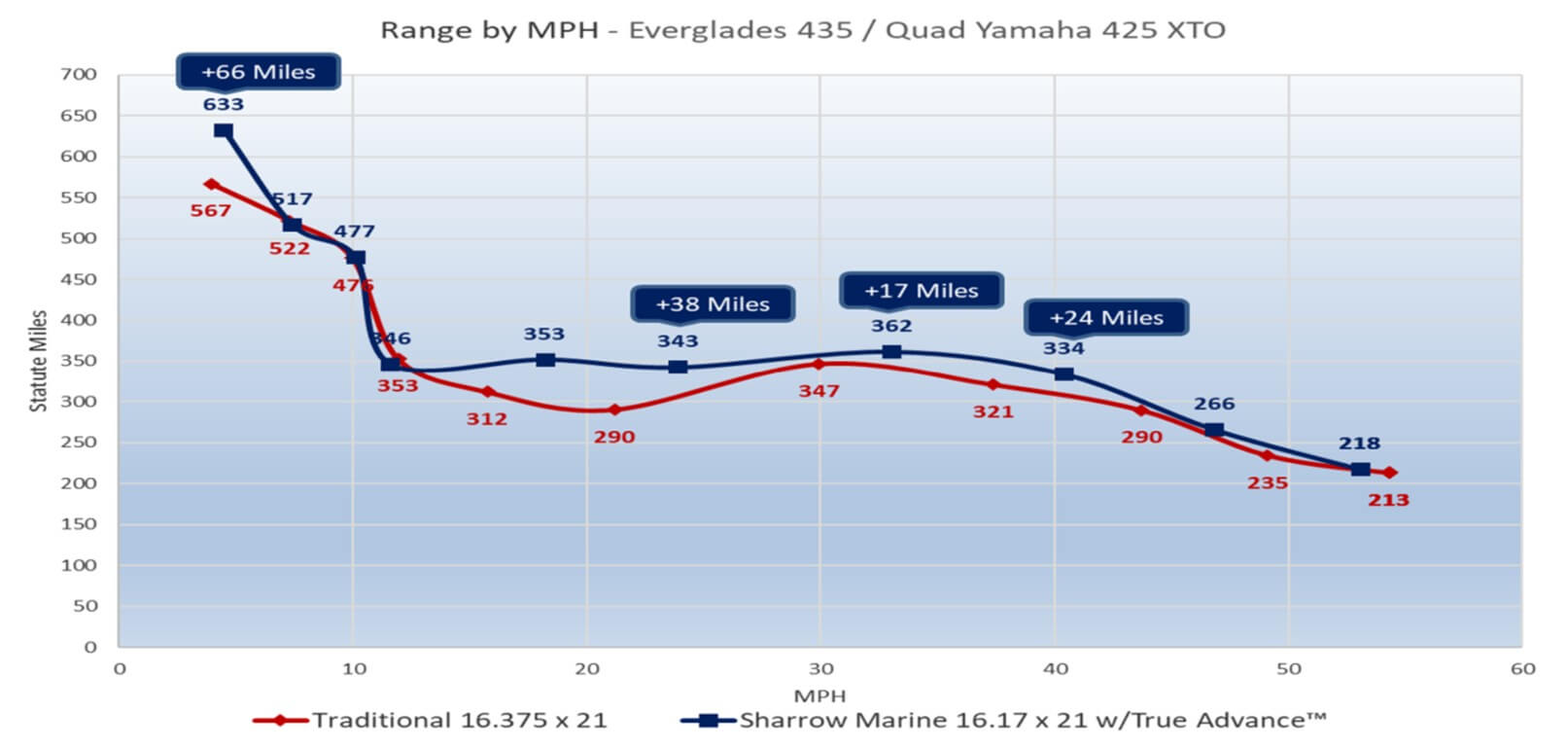

Greater range at trolling speed is a big plus in an offshore fishing boat like this one, while more range at planing speeds allows longer runs offshore or to distant islands with reduced concern about fuel use.

In this test, the Sharrow-equipped quad 425’s were capable of 38 more miles at about 25 mph than when equipped with the standard 3-blade propellers, and 24 more miles at 40 mph, a significant get-home advantage at the end of a long day, even though prudent skippers never run their tanks below 25 percent when offshore.

Sharrow propellers are nearly always more efficient than conventional propellers in the mid-ranges, and that was the case with the Everglades, peaking at 16% better at 2500 rpm. In this particular application, they maintained an advantage all the way to WOT.

Note that maximum efficiency was at 4500 rpm, which is the sweet spot for many four-stroke outboards in terms of fuel consumption.

Less Slip, Better Performance

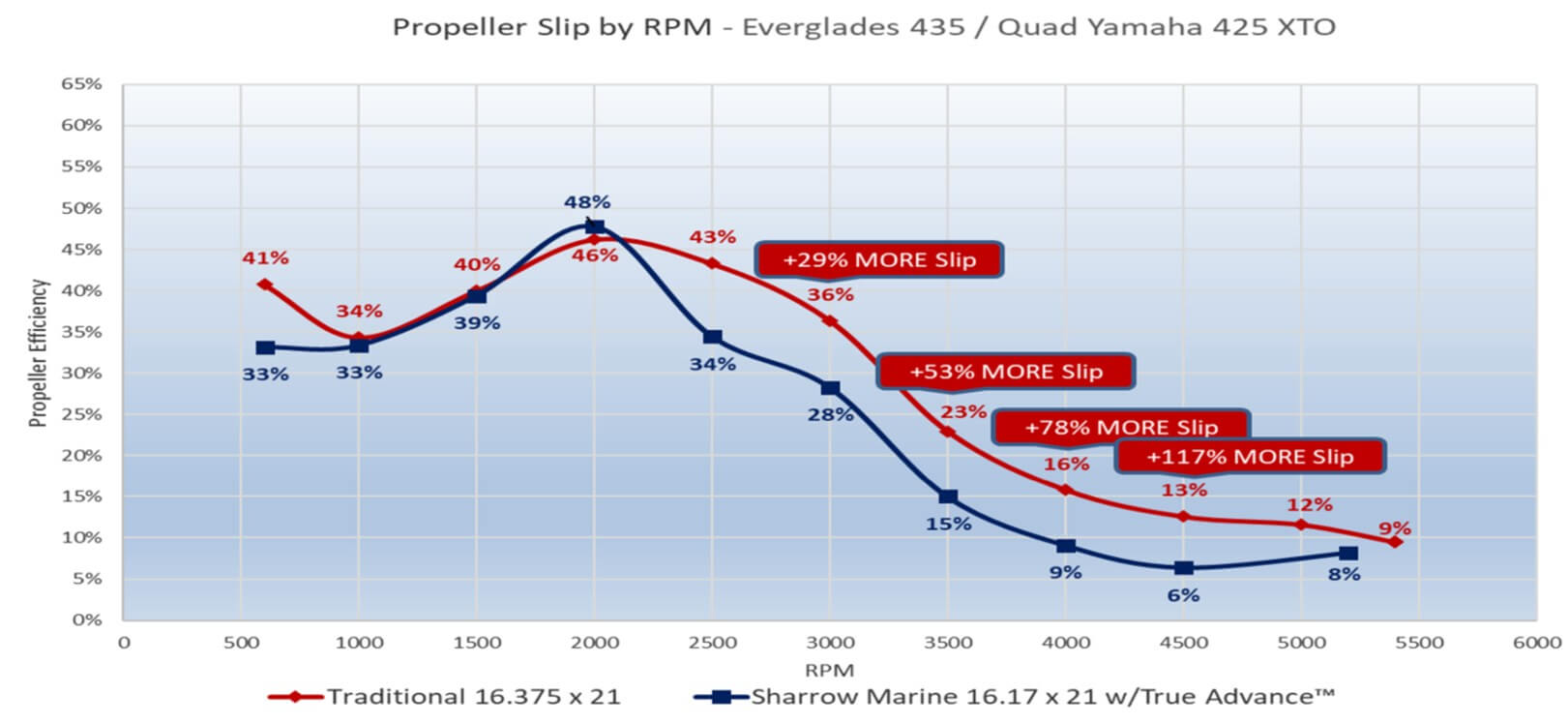

Slip is the difference between actual and theoretical travel resulting from a necessary propeller blade angle of attack. Some slip is inevitable in propellers “screwing” into water, but the slip declines in good designs as the rpm increases. (Some slip is essential in coming out of the hole or the engines would probably stall.)

The Sharrow’s in this application had a slip of just 6% at their most effective speed, 4500 rpm, and only 8 percent at WOT. The stock propellers had from 29% to a whopping 117% more slip at planing speeds.

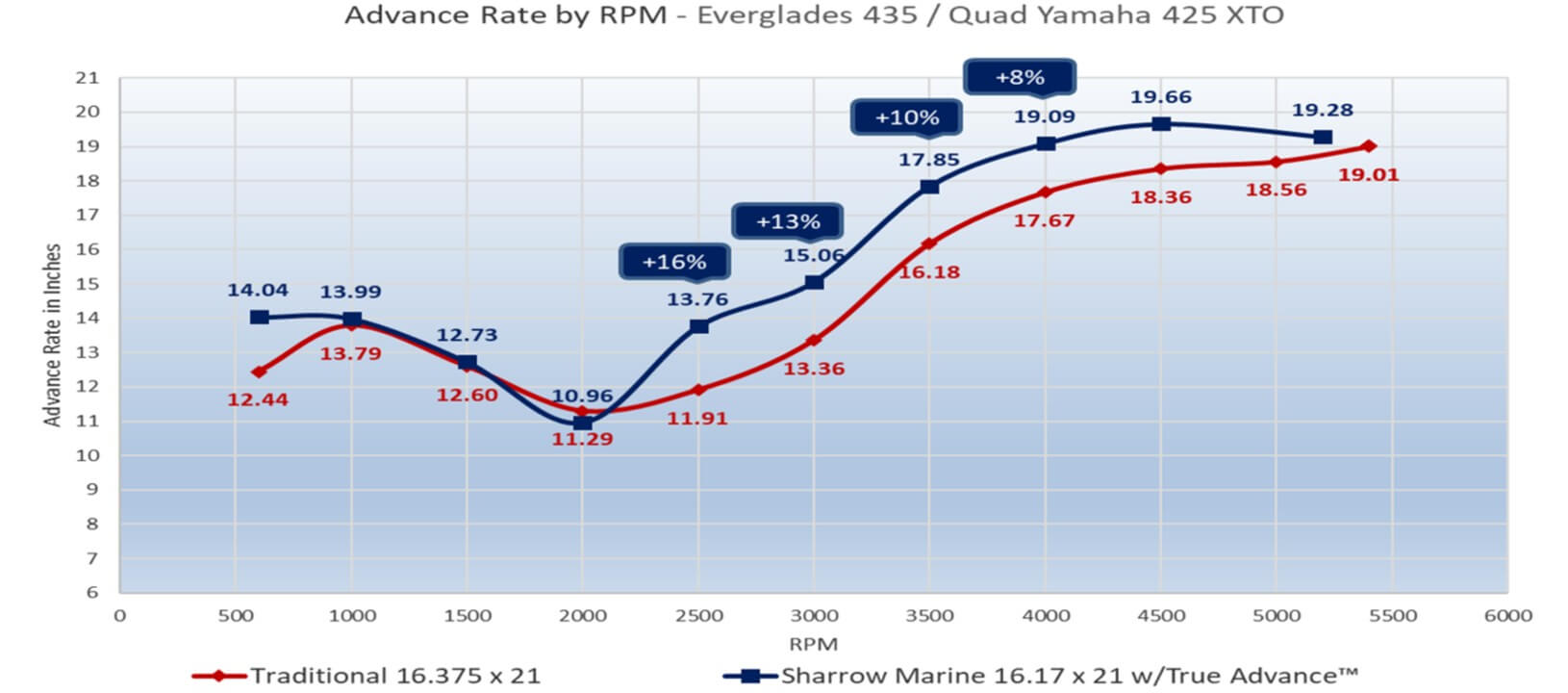

The advance rate is a measure of how far the boat travels forward with each revolution of the propellers. It can be compared to the pitch to gain an understanding of the efficiency of a given prop-set.

The 21” pitch Sharrow propellers showed a greater advance rate at idle, as well as beginning at 2500 rpm as the boat came on plane, and peaking at 4500 rpm, where the advance rate came relatively close to the designated 21”pitch at 19.66” per rotation.

Sharrow propellers are consistently faster in the mid-range than conventional propellers. While they’re not engineered for maximum speed, they provide higher speeds at most rpm levels short of WOT.

As shown here, the Sharrow’s were 2.4 mph faster just after coming on plane, and 3.1 mph faster at both 3500 rpm and 4500 rpm, though they were 1.2 mph slower at WOT.

When the operator can achieve a desired speed at lower rpm, he not only saves fuel but also reduces engine wear as well as noise and vibration.

Bottom line is that Sharrow propellers provide multiple advantages in performance, handling and fuel economy. The company also makes machined aluminum propellers for 40- to 200-hp engines as well as contra-rotating stainless designs to fit the Mercury 600 and the Suzuki 350.