Tech Talk - Wet or Dry Exhaust?

The diesel propulsion engine is the reliable heart that beats in the chest of every Nordhavn. More than any other piece of machinery, the exceedingly dependable diesel makes the Nordhavn way of life possible. However, it does present some issues that have to be dealt with along the way. One of the chief challenges is what to do with all the hot, loud and smelly stuff that comes out of it as it merrily chugs along.

There are two main camps of thought when it comes to marine exhaust systems for recreational boats: the wet and the dry. While wet exhaust systems are much more common for recreational boats in general, many builders of deep-sea passagemakers – including Nordhavn – like to take advantage of dry exhaust systems on a number of their models.

As their “wet” and “dry” monikers suggest, the differences between the two systems are substantial – and the main advantages and disadvantages of each system are equally distinct. Either way, the objective is the same: To safely carry away the byproducts of combustion along with no small amount of noise and heat. Engine cooling is closely tied to the exhaust system, and each type of exhaust will influence how the engine is cooled.

All Wet

Wet exhaust is called wet because seawater is mixed with the exhaust before it is routed out of the boat. Injecting seawater into the exhaust stream does a couple of things. It dramatically lowers the temperature of the exhaust run, so the fiberglass tube or rubber exhaust hose used to carry the exhaust away is not a threat in terms of burns or fire. And exhaust noise is suppressed as the water expands into steam and mixes with the exhaust.

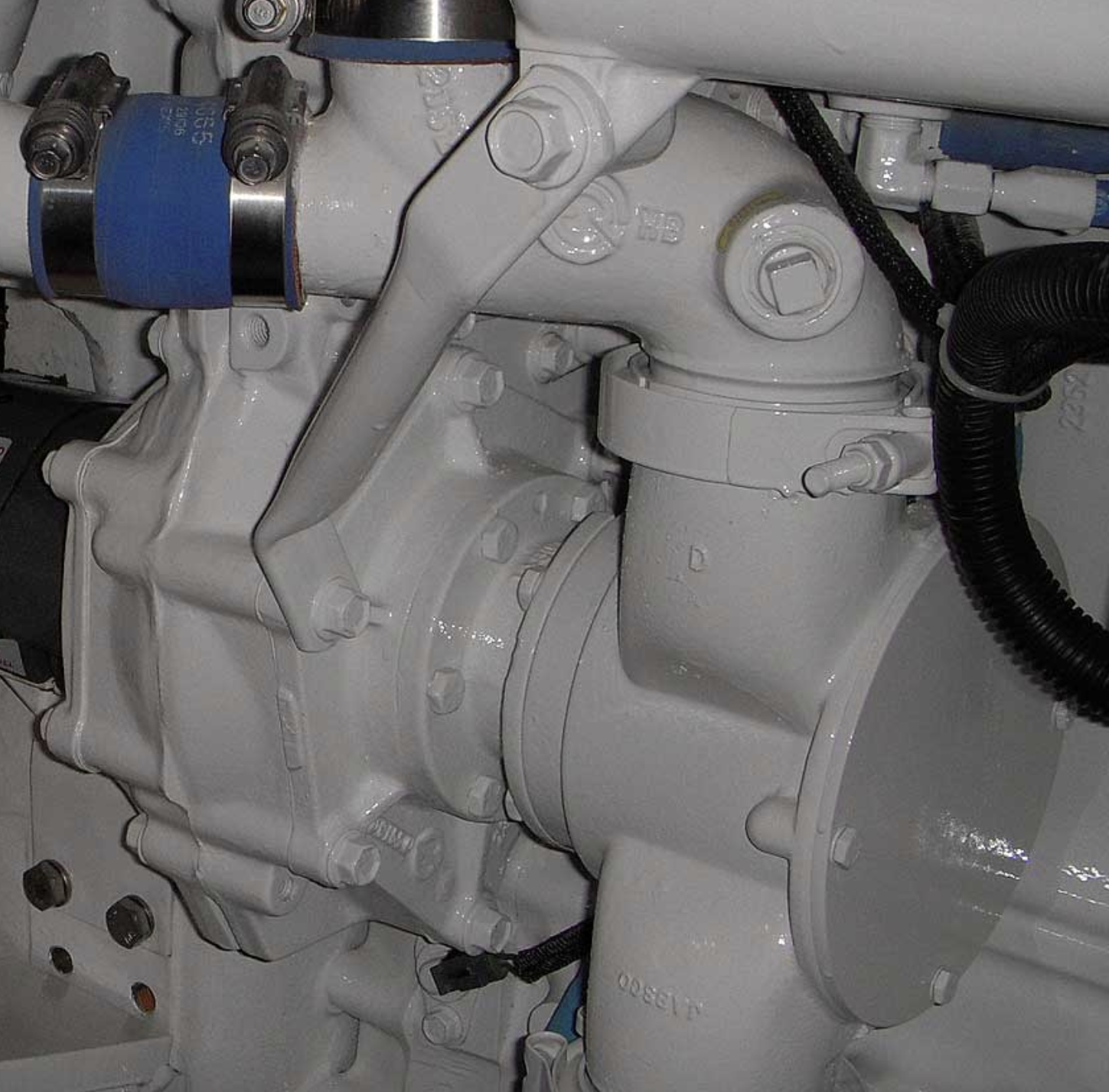

The water is provided by a dedicated seawater pump that typically routes seawater through the engine lube oil cooler, gearbox cooler, and main heat exchanger before being injected into the exhaust downstream of the exhaust manifold exit or turbocharger exit. After being injected into the exhaust the mixture is often routed to an inline muffler or water-lift muffler for further noise reduction before being ejected overboard.

In some cases a water separator muffler is also used, which quiets the exhaust even more and allows the gas portion be discharged above the waterline and the water portion to be quietly discharged below the waterline. Nordhavn includes these on its generators to eliminate the splashing noise created by the discharged cooling water, which quiets things down at night while on the genny.

A craft with a wet exhaust system is also often called a “heat exchanger” boat because a heat exchanger is being used inside that boat to cool the main engine. On the primary side of the heat exchanger a mixture of freshwater and antifreeze is being used to pull heat away from the engine block, on the secondary side seawater is being used to pull heat away from the freshwater and antifreeze mixture (this is the same seawater that is later injected into the exhaust).

Bone Dry

The main residual of dry exhaust is heat – and lots of it. Diesel engine exhaust gas temperatures can reach 1,200°F, and the surface of mufflers and exhaust pipes can reach between 400°F and 900°F. This means serious measures have to be taken to protect people and any surrounding equipment and structures from burns or heat damage.

Special lagging, insulated exhaust pipe lockers and even forced-air cooling blowers are all used to shield people and the area around the exhaust pipe from the extreme heat. The heat is only present while the engine is in operation or while it is cooling down, and a system that is subject to large temperature swings from an ambient 75°F or so at rest to 900°F while running must be designed using components that will operate without cracking or breaking due to thermal contraction and expansion.

This requires a great deal of thought during the design stage to ensure the system – from the engine all the way to the top of the stack – is safely secured yet is allowed to expand and contract time and again without failing. Slip joints, bellows and special pipe hangers all come into play here.

Because no water is used in the exhaust, the dry exhaust setup creates options in terms of engine cooling. Of course the heat exchanger method could be used, and the seawater simply discharged overboard instead into the exhaust. Or, a common alternative for passagemakers is to basically move the entire heat exchanger outside the boat where the passing water will carry away the heat much like a radiator does for a car.

In this case the heat exchanger is now called a keel cooler because it is mounted on the outside hull surface below the watetline (but not really on the keel) – giving us what most refer to as a “keel-cooled” boat.

With a keel-cooler heat exchanger on the outside of the boat there is no longer a need to bring seawater into the boat – so a keel-cooled boat does not need the thru-hull fitting, sea strainer, seawater pump, secondary piping and other components that are required by a heat-exchanger boat.

Dry Up or Get Wet?

The decision to use dry exhaust or wet exhaust is almost always made at the design stage and is not typically something a buyer can pick as an option. Any boat where high speeds are a top priority – and certainly any planing boat – is going to favor wet exhaust because the drag of a keel cooler would slow things down too much. This covers the vast majority or recreational boats.

Dry exhaust is lauded for greater reliability, so it is often the system of choice for slower-moving commercial workboats that see a lot of daily use – and, as it turns out, for a number of recreational passagemakers. Like the workboats that inspired them, recreational passagemakers prize reliability over speed, so in many cases dry exhaust is the system of choice if it makes sense on the whole.

A quick look at the main pros and cons of each system will help here:

Wet Exhaust:

Pros

- Far fewer heat issues with exhaust runs

- More interior space

- Easier to design and install

Cons

- Seawater pump failure could destroy engine

- Sea strainer, pump, injector elbow maintenance

- Exhaust can blow into boat in following wind

Dry Exhaust:

Pros

- No seawater pump to maintain (or fail)

- No seawater strainer to maintain (or clog)

- Exhaust released well above deck

Cons

- Dangerous heat

- Space accommodations for stack

- Complex design and construction

It’s clear what the main issues with the wet exhaust system are. It requires a hole in the boat for the intake, a strainer to filter the water and a pump that must be powered and maintained. Remember that this is the main source of cooling not only for the exhaust, but also the entire engine.

A clogged thru-hull or strainer, or a pump failure, will almost immediately manifest in extremely high exhaust temperatures that can destroy exhaust hose and fiberglass exhaust tubes, and loss of cooling to the engine can quickly cause the engine to seize and result in catastrophic damage.

Many boats with wet exhaust will include an exhaust temperature alarm and/or a loss of cooling water alarm to give the operator a few seconds to shut the engine down in the event of a loss of cooling seawater. These are not alarms to silence and causally inspect. If you get a high exhaust temperature alarm or a loss of cooling water alarm, shut the engine down NOW! Even a few seconds without cooling water can result in irreparable damage.

Another issue with wet exhaust is the potential to flood the engine with seawater when over cranking. While cranking the engine during starting the seawater pump is pumping water into the exhaust, and if the engine doesn’t start the muffler and exhaust tube will begin to fill up with seawater. Too many unsuccessful starting attempts could dump enough water into the exhaust to where it spills over back into the turbocharger (if installed), exhaust manifold, and cylinders, which can cause catastrophic engine damage.

The recommendation here is to open the valve or plug at the bottom of the muffler after 30 seconds of continuous cranking to drain the water before attempting to start again – this will ensure seawater doesn’t backup into the engine while starting. This is especially a concern with Nordhavn generator engines, all of which use wet exhaust systems.

On the dry side, most of the frustrations are with the system design more so than with operation and maintenance. The exhaust run needs to be designed and constructed to allow for thermal expansion, and it needs to be properly shielded to prevent burns and heat issues. Also, the exhaust locker will have to be included in the interior accommodations design and will eat up some space inside the salon, galley or other compartment.

Once all these issues are sorted out, however, there’s really not much for the owner to worry about or maintain – and after 25 years of building these systems, Nordhavn has perfected the process to ensure the necessary safety while minimizing the impact on interior space accommodations.

Low maintenance and reliability are top priorities for Nordhavn owners, which makes dry exhaust the system of choice for many owner/operators. They might have to sacrifice a small slice of interior space and put up with a little more radiant heat, but the payoff includes no strainers to clog, no impellers to break and no belts to fail – all of which add up to a nice increase in reliability.

And all appreciate the added benefit of releasing the exhaust gas out the stack high above the water where it can’t be blown into the boat by a following wind. While there are some situations where wet exhaust makes the most sense on a Nordhavn – typically on larger boats with twin engines – we always recommend dry exhaust anytime we can.

There’s less to maintain, there’s less to worry about and there’s no smelly exhaust getting blown into the salon – all good reasons to go dry.