Trim Tabs and Interceptors: How to Choose the Right Ones

On a boat that’s not trimmed properly, it’s likely that a captain and crew are not getting the most comfortable ride. One way to help smooth out the ride is to use trim tabs. It’s a misconception that boats need trim tabs only if they are not set up correctly in the first place. That may have been the case years ago, but today trim tabs can make a worthwhile difference on even the best-designed hulls.

Boats that perhaps benefit most from adding trim tabs are larger production boats in the 16’ to 26’ (5 m to 8 m) range that due to their tall profile lean (heel) into the wind. This is especially so with hardtop-equipped boats because the wind tends to blow any planing boat off course. To hold course the boat must be steered into the wind. When the steering wheel on any V-bottom planing boat, she will bank inwards when turning into the wind. A boat trying to cross choppy water can heel as much as 20 degrees. The boat’s tendency to flop onto one chine results in a harder ride that is uncomfortable and makes the boat harder to drive. The captain spends too much time trying in vain to correct the boat’s angle of heel through engine trim and throttle response.

Trim Tab Systems

Trimming a boat using the outboard or sterndrive will not stop heeling. When the lower unit is used with trim tabs, it’s a different story and the result is more efficiency, performance and better overall handling. Not including the outboard or sterndrive lower unit, there are essentially four different systems available when it comes to adjusting a boat’s attitude. First, we have trim tabs that are adjusted by the captain. Next are automatic or fixed self-leveling systems that react instantly to water pressure. If you don’t want to fix anything to the transom, check out foils that bolt to the cavitation plate on the outboard or sterndrive. In recent years we have seen another option, the interceptor, that brings a whole new dynamic to trim tab design.

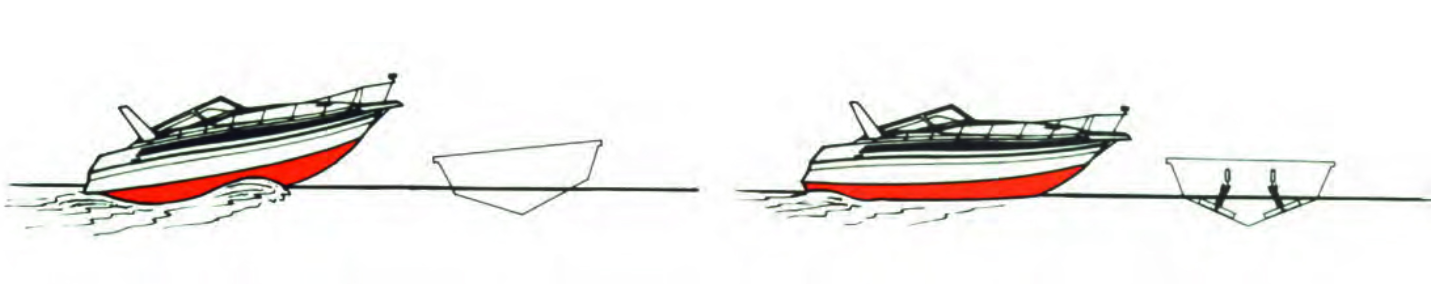

While there are many varieties of trim tabs, they all essentially do the same job to adjust the boat’s attitude. Trim tabs are hinged plates mounted on the transom that are forcibly lowered to deflect the water flow downwards, thereby providing upward alter the bow’s position. When trim tabs are set up for independent operation, athwartships trim can be adjusted to favor one side by simply lowering one plate. When the starboard side trim tab is lowered, the starboard side lifts and consequently the portside bow drops and vice versa.

Using various tab combinations, an operator can trim to best cope with the negative aspects of sea, wind or load conditions. Individual boats require different amounts of tab to produce the best results, but always they should be used with finesse. If the tab is lowered too far, its braking effect will be too pronounced, killing speed, sucking horsepower and throwing the hull out of balance. Generally the less tab that can be used the better.

Knowing when your boat is trimmed correctly is a matter of feel and experience. What works for one doesn’t always apply for another. Generally, if the horizon ahead is level and the water is peeling off the chines somewhere about under or just aft of your driving position, you’re reasonably close. If there is a huge bow wave and you’re slamming into every wave, then back off and trim out a little — you will be surprised at the different ride you get, particularly with deep-V boats. In our experience, the most gains can be made with smaller boats mainly because a changing sea, shifting passenger load or lessening fuel load will affect a small hull more than a larger one.

Interceptors — Same But Different

Until recently, Interceptors were used to adjust trim on larger boats longer than 39’ (12 m). Now they are readily available and specifically designed for trailer boats. The most popular interceptors are Humphree, (also marketed through Volvo Penta as Interceptor) and Zipwake.

An interceptor is a blade mounted on the transom that drops straight down to create pressure underneath the hull. Because of the interceptor’s blade-style design, a minor deployment is all that’s needed to create a large lifting force beneath the hull. This alters the vessel’s running trim resulting in a lower wave resistance. The interceptor’s main function is to create lift. With reduced wave resistance, the interceptor generates more lift force and less drag than trim tabs. The key to achieving good results how quickly the system reacts to adjustments. Traditional trim tabs are comparatively slower because they need more surface area to achieve the desired result.

Since the interceptor blade does not push away the water, it can move more easily. All interceptor systems are electrically powered. They require minimal power to move the blade up and down, even under high-speed operation. The interceptor blade is controlled by an electronic actuator designed to move the blade a full stroke as fast as one second, which is considerably faster than conventional trim tabs. Interceptors are lighter than most trim tabs and can integrate more easily to the transom. In some cases, it can be custom-shaped to follow a bottom’s contours.

That means it is possible to fit a trim system over a propeller tunnel or partly over the chine. Also different from most metal-based trim tabs, interceptors are constructed of composite materials. This results in lighter construction that nets almost zero added mass. It also eliminates worries regarding corrosion and the need for sacrificial anodes.

A Broader Audience

Swedish interceptor maker Humphree was formed in 2001 and since that time has provided interceptor systems for around 1,500 boats from 39’ to 328’ (12 m to 100 m). However while the original Humphree series are offered in sizes from 13.8” to 59” (350mm to 1500mm) and various designs to fit hull shapes for boats from 39’ to longer than 650’ (12 m to 200 m+), they recently developed the X Series, a standardized interceptor for boats as small as 24’6” (7.5 m).

This X Series features all the same automated features — auto list, coordinated turn and active ride control — of the larger Humphree systems. They are available in four standard sizes; 11.8” (300 mm), 17.7” (450 mm), 23.6” (600 mm) and 29.6” (750 mm). The Volvo Penta Boat Trim System (BTS) caters for the smaller boat range and is recommended for boats 5m – 12m and for all drive systems including outboards. BTS is easy to manually operate from the control panel where the trim indicators show the position of the interceptor units. With the automatic option, you can further enhance comfort and safety by just pressing the DzAdz button and the system automatically keeps the pre-set, preferred boat attitude.

Another Swedish company, Zipwake also offers smaller units for trailer boats as well as larger cruisers. The Zipwake, Dynamic Trim Control System (DTCS) comes in four model sizes, suitable for planning and semi planning boats from 6m to 18m. One unique feature to Zipwake is that it offers two alternatives for the cable through the transom, either above the waterline or concealed through the hull. The above-waterline option is an important factor to consider when retrofitting units to trailer boats with molded or glassed in cockpit decks that make access difficult. Each Zipwake control panel is fitted with an internal GPS and equipped to read additional GPS source information (NMEA2000 and NMEA0183). The Zipwake Dynamic Trim Control System will automatically use the source with the best information to trim the boat. While the system is automatic, it also lets the operator adjust the pitch and roll settings manually.

Trim Tab Design

When trim tabs first arrived, they were an all-manual affair. You set them for what you felt would be the best attitude for the boat by winding a worm-screw device. They couldn’t be adjusted underway, but you could stop, adjust and carry on. Next came hydraulically operated tabs like those from Bennett Marine that relied on oil pressure to push down the tabs.

Advancements have been made in tab design and in the mechanisms that operate them. Today we have two main types of actuator mechanism, electro-mechanical and electro-hydraulic. The current electro-hydraulic systems are a development of the original hydraulic systems that use a 12-volt reversing motor to drive a high-pressure hydraulic pump and oil reservoir in a self-contained unit that mounts on the inboard side of the transom near the trim tabs.

A short hydraulic line connects the pump to the ram, often through the ram’s base plate by way of a hole drilled in the transom. This means there are generally no external oil lines to catch or foul. Switches at the dash control the tabs and solenoids on the motor handle the heavy electrical switching so the wiring to the dash can be relatively light and easy to install. Electro-mechanical is basically an electric motor coupled to a worm drive. They react quickly and can generally withstand greater loads than a hydraulic system. They also don’t leak.

Trim Tab Size

Trim-tab size required depends on your boat, its performance and what you want to achieve. A rule of thumb is that for an average 9.1” (229 mm_ long (transom to trailing edge) plate, 1” (2.5 cm) of tab width is needed for every 11.8” (30 cm) of boat length (i.e. the tab width should be about 1/12 of the boat length). Plates are made from a variety of materials including cast aluminum, fabricated stainless steel, GRP and even advanced composites. Likewise, ram sizes and the numbers required to activate a trim tab cannot be decided without knowing all the information, so buyers should be guided by a reputable supplier.

The stresses and strains a trim tab endures are enormous and incorrectly installed or improperly supported plates will more than likely bend or break. Contrary to popular belief, the neutral position for a transom-mounted trim tab is not when it forms a continuation of the planing surface, but when it is raised slightly to align with the flow of the water leaving the transom. As an extension of the planing surface the tab is still generating lift. When the tab is fully raised, air should flow in under the plate. Once this happens the tab ceases to exert force and the hull is restored to its normal trim. The position of the tab relative to the planing surface and the chines is critical so if you are going to fit them yourself read the manufacturer’s instructions thoroughly.

Remember, as almost all outboards and sterndrives now have power trim, the primary reason for fitting trim tabs to boats powered by them is to more easily keep the boat from heeling into a cross-wind. Locating the tabs as far apart as possible minimizes the amount of uplift force needed to correct for heel into a crosswind. This reduces the downward angle needed on one tab, which in turn minimizes the drag force incurred. Put more succinctly, the farther apart the tabs can be fitted the better.

Doing the Thinking for You

There are two types of self-leveling trim tabs, auto leveling and smart or fixed tabs. They are designed to do the thinking for you and they do it a different way and at a different cost. Just about every manufacturer offers an auto leveling systems — Insta Trim, Lenco, Bennett and Lectrotab,— that react to boat trim and balance using sensors to detect your boat’s deviation and sends a signal to the central processing unit (CPU).

The CPU is the brains of the system and determines how the trim tabs should be adjusted and communicates this corrective information to the master module. The on-board computer learns and stores the characteristics of the boat and uses this information for precise, efficient trim-tab correcting. The most inexpensive system is the simple fixed tab, such as the Bennett SLT, which self-regulates by reacting instantly to water pressure. These reasonably inexpensive tabs are designed for powerboats in the 10’ to 20’ (3 m to 6 m) range, are totally self-contained and don’t come with any of the baggage of hydraulic and electrical systems or console switches. Self-contained units that attach to the boat’s transom, they work with water pressure to adjust the boat’s attitude.

The tabs use a nitrogen-filled gas actuator situated between the plate and connection point at the transom to control trim. Like a gas-controlled spring that expands to keep the tabs down while at rest or at low speeds, then as the speed and water pressure increase, the plate pushes on the actuator and it retracts upwards. When the boat slows, the actuator extends the tab down again. It’s that simple.

Whatever system an owner decides on, they all work to improve a boat’s ride. Some probably work better than others and in the end it’s about finding one that suits your boat and of course your budget.