Access More Boat Tests

Already have an account? Login

Front Runner 26CC w/ Cox CXO300 Diesel Power (2023-)

COX CXO300 Diesel Power

Brief Summary

The Cox CXO300 is a 300-hp diesel outboard that started production in July 2020 in a world-class factory in the U.K. The engine was purpose-designed and built for marine applications for recreational, commercial and military use, and is not a warmed-over automobile engine. In two years the Cox CXO300 has become the leading diesel outboard in the world with over 40 dealers world-wide. Its leading distributor in the U.S. is Ring Power in St. Augustine, FL.

Engine Specifications:

TYPE OF ENGINE Diesel

NUMBER OF CYLINDERS 8

HORSE POWER 300HP

CONFIGURATION V8 60-Degrees

WEIGHT 866 lbs

FUEL TYPE Diesel

FUEL DELIVERY Common Rail Direct Injection

SHAFT LENGTH OPTIONS 25", 30",35"

SHAFT THROTTLE CONTROL Digital

DISPLACEMENT 266 cu in.

STEERING CONTROL Digital

RECOMMENDED FUEL Diesel

ALTERNATOR OUTPUT Up to 100 Amp

CARB RATING Tier 3

Test Results

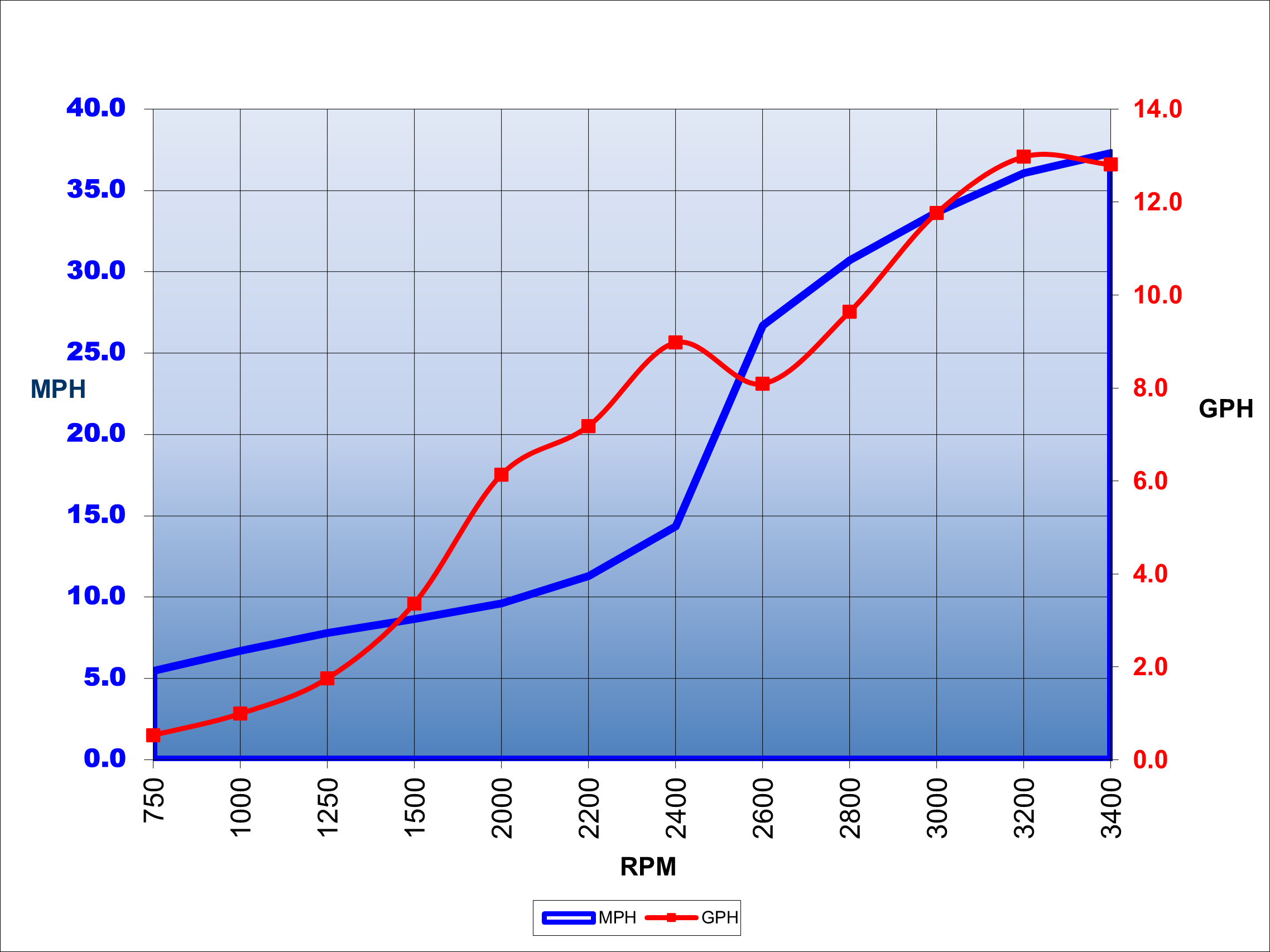

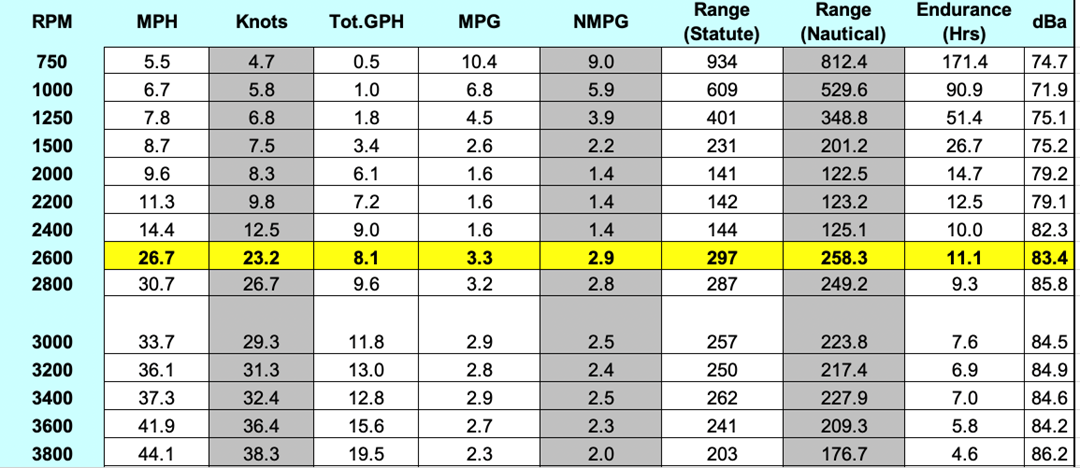

| RPM | MPH | Knots | GPH | MPG | NMPG | SM | NM | dBa |

|---|---|---|---|---|---|---|---|---|

| 750 | 5.5 | 4.7 | 0.5 | 10.4 | 9 | 934 | 812.4 | 75 |

| 1000 | 6.7 | 5.8 | 1 | 6.8 | 5.9 | 609 | 529.6 | 72 |

| 1250 | 7.8 | 6.8 | 1.8 | 4.5 | 3.9 | 401 | 348.8 | 75 |

| 1500 | 6.7 | 7.5 | 3.4 | 2.6 | 2.2 | 231 | 201.2 | 75 |

| 2000 | 9.6 | 8.3 | 6.1 | 1.6 | 1.4 | 141 | 122.5 | 79 |

| 2200 | 11.3 | 9.8 | 7.2 | 1.6 | 1.4 | 142 | 123.2 | 79 |

| 2400 | 14.4 | 12.5 | 9 | 1.6 | 1.4 | 144 | 125.1 | 82 |

| 2600 | 26.7 | 23.2 | 8.1 | 3.3 | 2.9 | 297 | 258.3 | 83 |

| 2800 | 30.7 | 26.7 | 9.6 | 3.2 | 2.8 | 287 | 249.2 | 86 |

| 3000 | 33.7 | 29.3 | 11.8 | 2.9 | 2.5 | 257 | 223.8 | 85 |

| 3200 | 36.1 | 31.3 | 13 | 2.8 | 2.4 | 250 | 217.4 | 85 |

| 3400 | 37.3 | 32.4 | 12.8 | 2.9 | 2.5 | 262 | 227.9 | 85 |

| 3600 | 41.9 | 36.4 | 15.6 | 2.7 | 2.3 | 241 | 209.3 | 84 |

| 3800 | 44.1 | 38.3 | 19.5 | 2.3 | 2 | 203 | 176.7 | 86 |

Specifications

| Length Overall |

26' 7.92 m |

|---|---|

| Beam |

8' 11" 2.72 m |

| Dry Weight |

5,500 lb 2,495 kg |

| Tested Weight |

7,460 lb 3,384 kg |

| Fuel Capacity |

100 gal 378.5 L |

| Water Capacity |

50 gal 189.3 L |

| Total Weight |

7,460 lb 3,384 kg |

Acceleration Times & Conditions

| Time to Plane | 4.5 |

|---|---|

| 0 to 30 | 14.3 |

| Props | 16x 19.5" |

| Load | 4 persons; 50 gal. fuel; 50 lb gear |

| Climate | 78 deg., 80 humid; wind: 5-10 mph, seas:<1 |

Engine Options

| Tested Engine |

1x Cox CXO300 |

|---|---|

| Std. Power | |

| Opt. Power |

Brief Summary

The Cox CXO300 is a 300-hp diesel outboard that started production in July 2020 in a world-class factory in the U.K. The engine was purpose-designed and built for marine applications for recreational, commercial and military use, and is not a warmed-over automobile engine. In two years the Cox CXO300 has become the leading diesel outboard in the world with over 40 dealers world-wide. Its leading distributor in the U.S. is Ring Power in St. Augustine, FL.

Mission

The Cox CXO300 is designed to provide high torque and extraordinary fuel efficiency for boats currently using gasoline outboard engines which have relatively low torque, which need extended range, low maintenance, and the power necessary to get relatively heavy boats on plane. It was also designed to replace inboard gas and diesel engines in boats up to about 40,000-lbs. (18,181 kgs.) where diesel torque and efficiency is needed and inboard power is problematical to quickly repair or replace – or, which need additional cargo or storage space aboard.

Specifications

The Back Story

In 1966 the 20-year-old Charles Good was on his mother’s wooden sailboat anchored off Greece’s Ionian Islands. He was decanting gasoline into a smaller container when he spilled a significant amount on the deck. A dangerous fire erupted, but happily no one was hurt. Good never forgot the incident and often wondered why no one had invented a diesel outboard engine.

Fast forward 42 years to 2008 when Charles Good was working at a small investment bank in the U.K. A project needing funding kept hitting his desk, he remembers, and it was for a lightweight diesel engine. The designer was a Formula 1 racing engineer who had a reputation for thinking out of the box. His name was David Cox.

Good took the plans to a neighboring engineering firm, Ricardo PLC, a leading UK engineer firm that has a long history in the auto industry, among others, for creating efficient solutions to difficult problems. They liked the design and that was all Good needed to commit his investor group to develop the engine; Cox Powertrain was founded.

The first Cox prototype engine was built 2010. Three years later the engine was introduced – the first outboard diesel debut in the 21st century. Sadly, David Cox passed away during the development years, but he lived long enough to know that his design would become a commercial reality

In the summer of 2020 the first engines were delivered from the company's state-of-the-art factory in southern England. By that time it had a staff of 150 people and dealers had been set up in 21 countries. We have read figures that range from $125 million to $200 million has been spent by the investment group so far on the engine’s development.

Why Consider a Diesel Engine?

In case you haven’t noticed, diesel engines are used exclusively in applications that call for lots of power, for example in 18-wheel over-the-road trucks that haul heavy cargo, bulldozers, and farm tractors, just to name a few.

There are several reasons diesel engines are considered better than gasoline engines, depending on the application:

1.Fuel Efficiency: Diesel engines are more fuel efficient for several reasons:

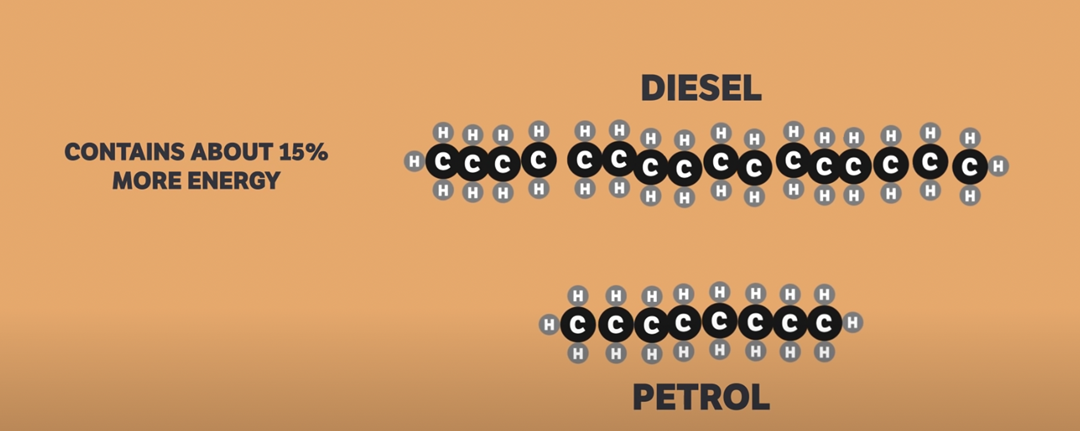

- Diesel fuel has more hydrocarbon molecules than does gasoline of any octane.

- A Gallon of gasoline has about 114,000 BTUs on energy per gallon, and diesel fuel has 129,000 BTUs per gallon. So, diesel fuel has 13% more energy to start with.

- Diesel engines are inherently more thermal efficient. See below.

2. Durability: Diesel engines are typically built to withstand more wear and tear than gasoline engines. This means their useful life is far longer than gas engines. Further, when they begin to show their age, they can have what is known as a “Major Overhaul” in which cylinder sleeves are changed, and other parts replaced, etc., for a fraction of the new engine cost.

3. Lower Maintenance: Diesel engines typically require less maintenance than gasoline engines. There are 5 major reasons:

- A simpler ignition system – No spark plugs, no coils, no timing chains, etc.

- Lower RPM Range – Typically, diesel engines run at 30% to 50% lower RPMs than gas engines, which means the piston runs up and down through the cylinder fewer times, and valves, connecting rods, valve lifters and the pistons themselves all work less and have less wear.

- Fuel lubrication – Diesel fuel itself has lubricating prosperities, which helps reduce friction on cylinder walls, piston rings, and on valve guides.

- Robust construction – Diesel blocks must endure compression ratios of 16:1, typically, which means they must be stronger and have more material between the cylinders, in addition to having large drive shafts, and gears to handle their prodigious torque.

- Fuel and filtration – 95% of the gasoline sold in the U.S. has 10% ethanol and phase separation introduces water into the engine which can cause rust. Further, diesel engines have a more extensive filtration system -- in order to remove impurities, water and sludge and biomass from the fuel -- than do gas engines.

4. Safety: Diesel fuel is less volatile than gasoline and therefore less likely to ignite in the event of an accident. Gas fumes are easy to ignite by a spark and cause a fire or an explosion.

5. Torque: Diesel engines are known for their high torque output, which can be particularly advantageous for powering heavy vessels, getting them on plane sooner and keeping them there, at lower RPM.

Why are Diesel Engines More Fuel Efficient?

There are 7 basic reasons why diesel engines are inherently more fuel-efficient than gasoline engines--

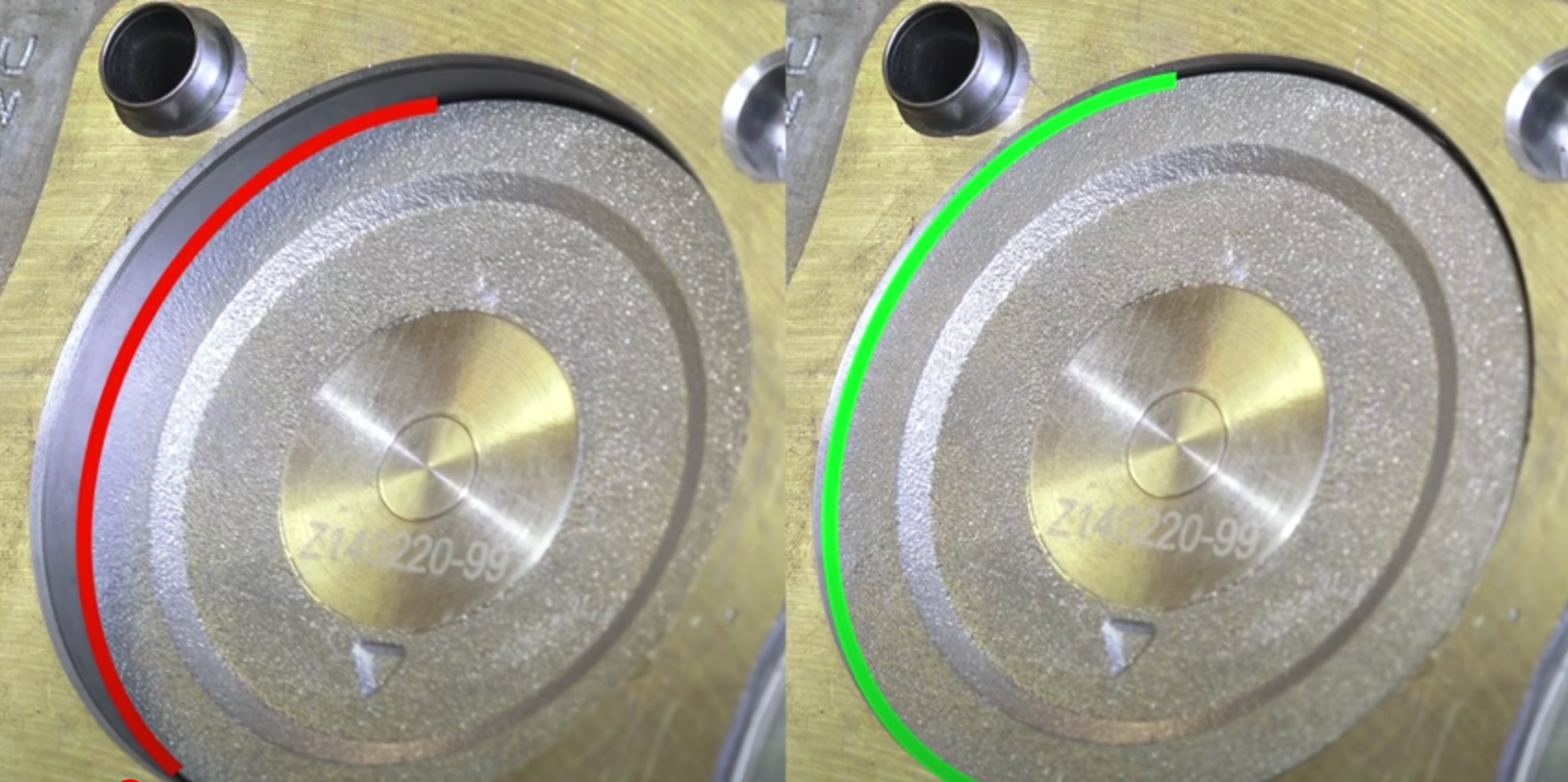

1. Higher Compression Ratio: Diesel engines have a much higher compression ratio compared to gasoline engines. The high compression ratio allows for better thermal efficiency as it leads to more complete combustion of the fuel-air mixture, and therefore more energy pushing down on the piston.

- Diesel engines typically have a compression ratio of 16:1 (as does the Cox diesel), and gas engines are about 10.4:1.

- Compression combustion means all of the fuel-air mix explodes at one instant, whereas spark ignition starts combustion at the plug and it spreads to the rest of the fuel-air mix over time (albeit, and very short time).

2. Fuel Properties: Diesel fuel has a higher energy density than gasoline. See above.

3. Leaner Fuel-to-Air Ratio: Naturally-aspirated gas engines rely on atmospheric pressure and a vacuum in the cylinder to inhale the air-fuel mix and has an optimal fuel air mix of 14:1. Diesel engines are now virtually all turbocharged, cramming lots of air into the cylinder at air-fuel mixtures ranging from 70:1 to 150:1. The additional air (which is 22% oxygen) makes diesel combustion more, therefor less wasted fuel.

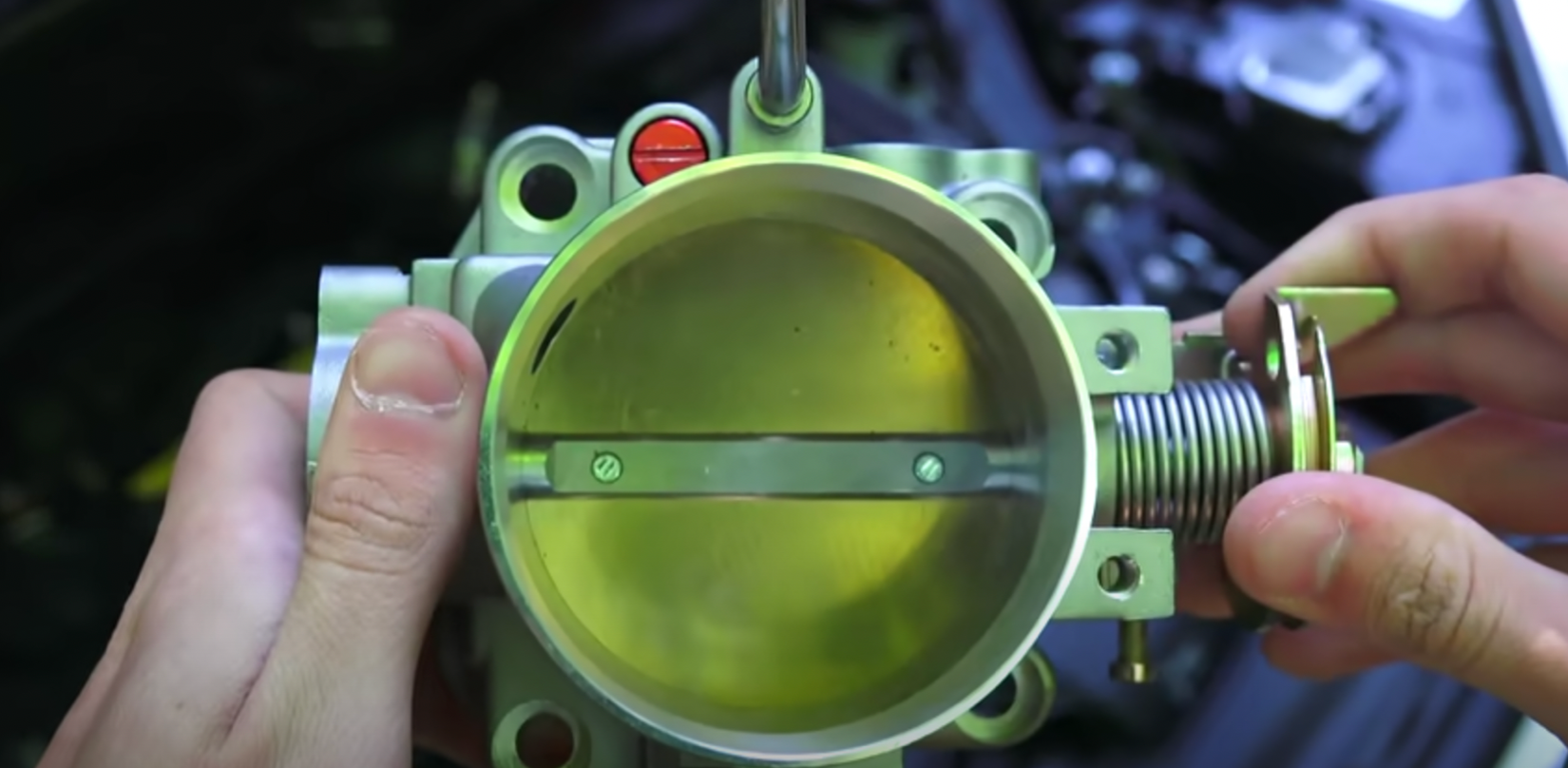

4.Direct Fuel Injection. By having diesel fuel injectors in the cylinder the amount of fuel and timing of its injection can be precisely calibrated by the ECM. Gas outboard engines all have MPI (Multi-Port Injection) which means that the fuel is injected into the intake manifold which is farther way from the combustion chamber and less controllable. (This is why modern gas automobile engines have direct fuel injection into the combustion chamber.)

5.No Throttling Losses: Diesel engines do not rely on a throttle valve to regulate air intake, unlike gasoline engines. Throttling losses occur when the throttle restricts the airflow into the engine, causing pumping losses and reduced efficiency. Diesel engines operate without throttles.

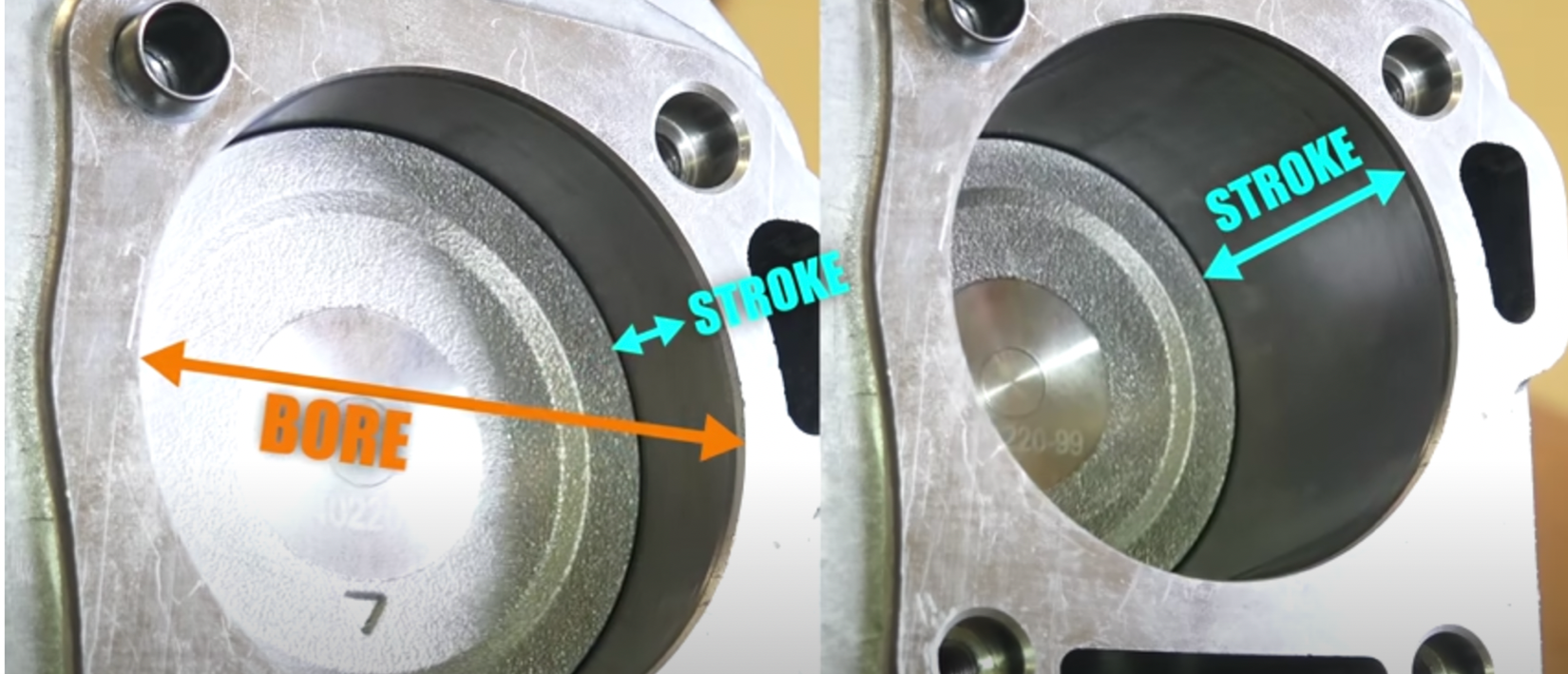

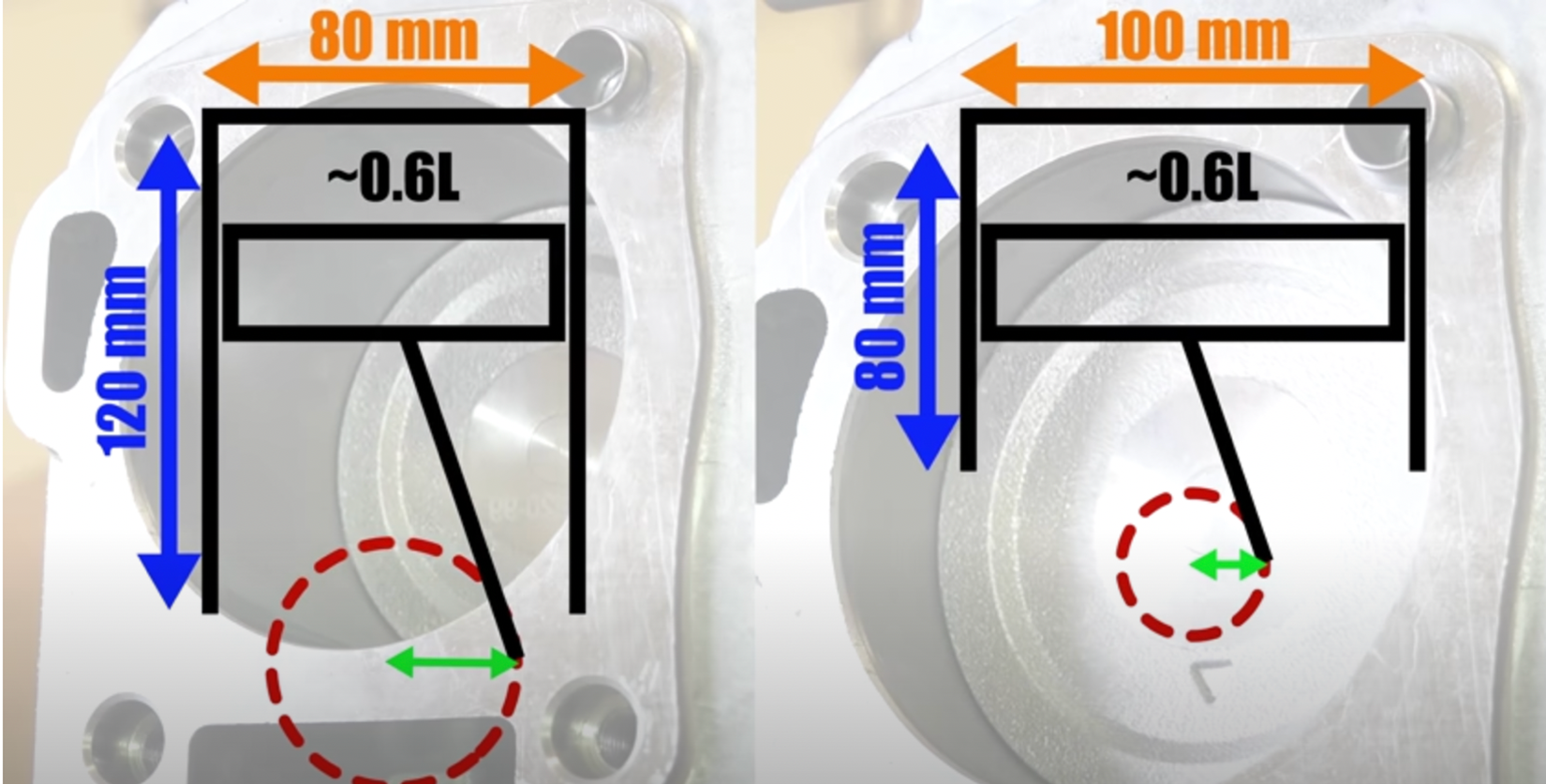

6.Longer Stroke Length: Diesel engines typically have a longer stroke length than gasoline engines. A longer stroke allows for a larger expansion ratio, which increases the engine's efficiency by extracting more energy from the combustion process. This longer stroke length also acts as a slightly longer lever on the crank shaft for added torque.

Conversely, because of the longer stroke length and greater lever arm the diesel engine can’t make as many revolutions per minute as can a gas engine whose piston does not have far to move. The result is that diesel engines usually cannot turn the high revs of a gas engine.

7. Lower RPM Range: Diesel engines typically operate at lower RPMs compared to gasoline engines. Lower RPM means reduced friction on all of the engine’s drive components and improved fuel efficiency.

What is Torque?

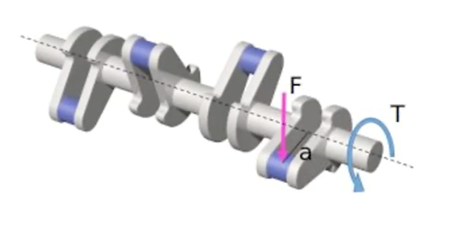

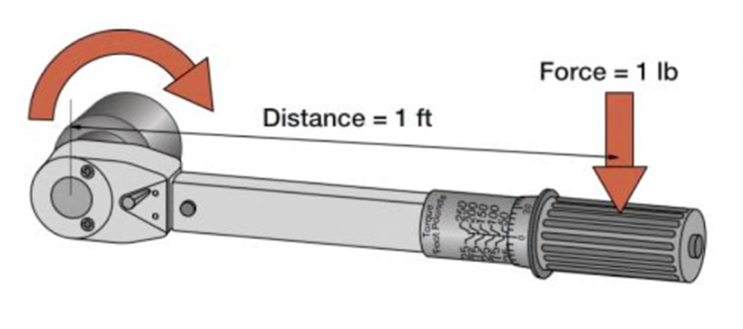

Torque is a measure of the rotational force or twisting force applied to an object, in the context of engines, at the crankshaft or at the prop shaft. In this report we will use it at the prop shaft.

Torque is measured generally in the U.S. in pound-feet or foot-pounds (lb/ft or ft/lb) which are the same thing. In the rest of the world, Newton-meters (Nm) is the metric measurement used. In this report we will use pound-feet to minimize confusion.

When measuring torque and horsepower in outboard engines, dynamometers are used. The higher the torque, the more power the engine exerts and the greater the propeller thrust.

Torque determines the engine's power output, acceleration capabilities, load handling ability, fuel efficiency, and overall driveability.

What is the difference between Torque and Horsepower?

Horsepower combines torque and RPM to measure the engine's overall power output and performance capabilities. The mathematical definition of horsepower is: Horsepower = (Torque x RPM) / 5252. So, torque, along with RPM, is one component making up horsepower.

Torque is responsible for acceleration and low-end power at relative low RPM, while horsepower grows with RPM and relates to top speed and sustained performance.

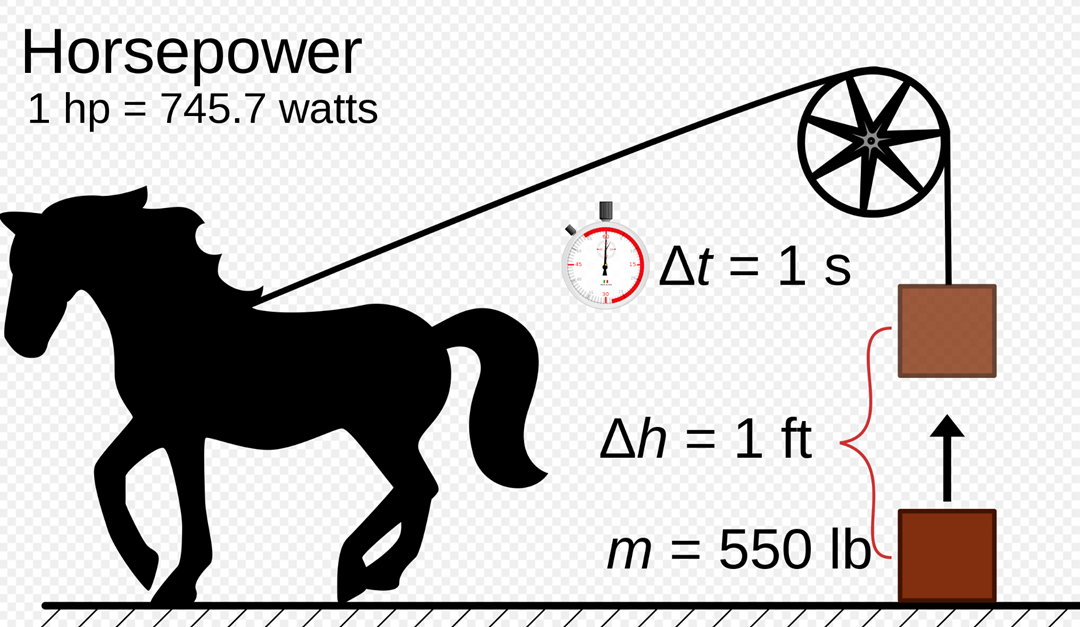

Horsepower quantifies the power output and rate at which work is done by an engine. James Watt in 1783 created the term horsepower to measure the time it took a draft horse to raise 550-lbs (250 kgs.) one foot in one second.

Why is Torque so Important for Outboard Boats?

1. Power Output: Torque is directly related to the engine's power output. The greater the torque, the more force the engine can exert on the prop shaft, resulting in greater power and acceleration.

2. Acceleration: Torque plays a crucial role in accelerating a boat. It is responsible for overcoming the inertia of the boat at rest. Higher torque enables quicker acceleration and better low-end responsiveness.

3. Getting on Plane: Torque is essential for engines to handle various loads effectively. Getting a boat on plane, climbing up out of the hole and over the boat’s bow wave takes tremendous thrust possible because of torque.

4. Greater Load Handling: Once on plane, higher torque delivers the power keep a heavy boat, or a boat with a lots of passengers on plane and maintain performance under load.

5. Fuel Efficiency: By being able to haul the same load as a gas engine at fewer RPM, and fewer combustions, the diesel outboard engine naturally burns less fuel.

6. Driveability: Torque influences the engine's overall driveability and responsiveness. Higher torque provides a stronger and smoother acceleration, allowing the boat to get on plane faster without having to put the hammer down. It allows the operator to make sharp turns at high speed without ventilating the props and losing speed. And at the dock, the boat is more responsive to each little nudge of the throttle to move the boat in the desired direction without having to rev the engine, which can lead to loss of control.

The Cox CXO300’s Torque

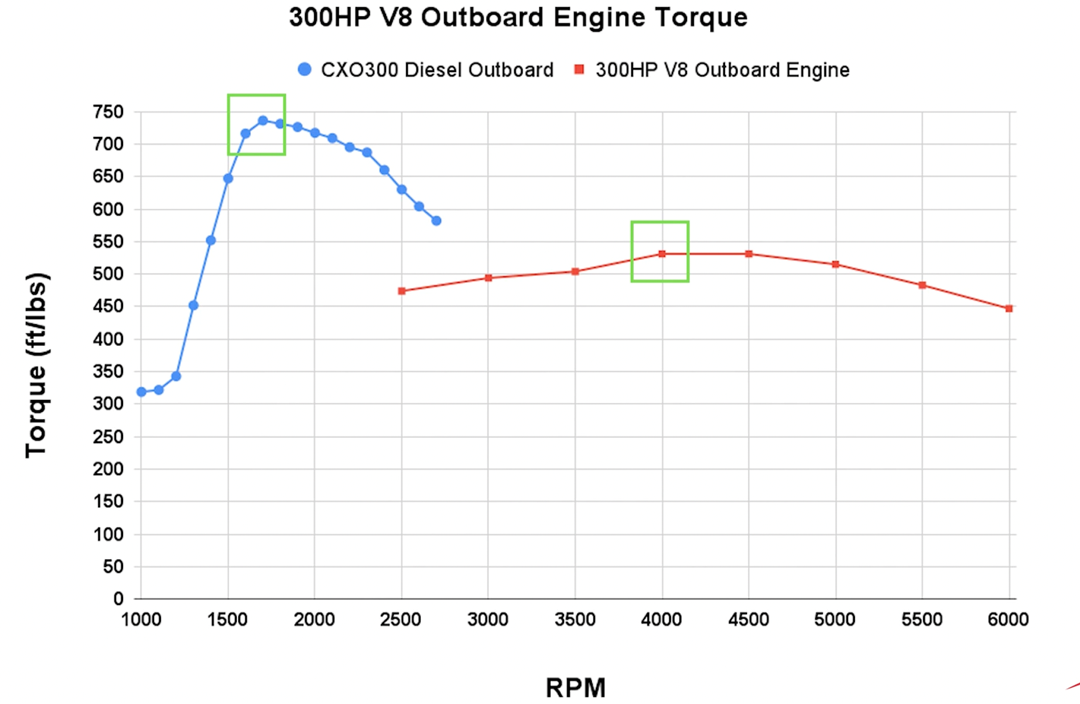

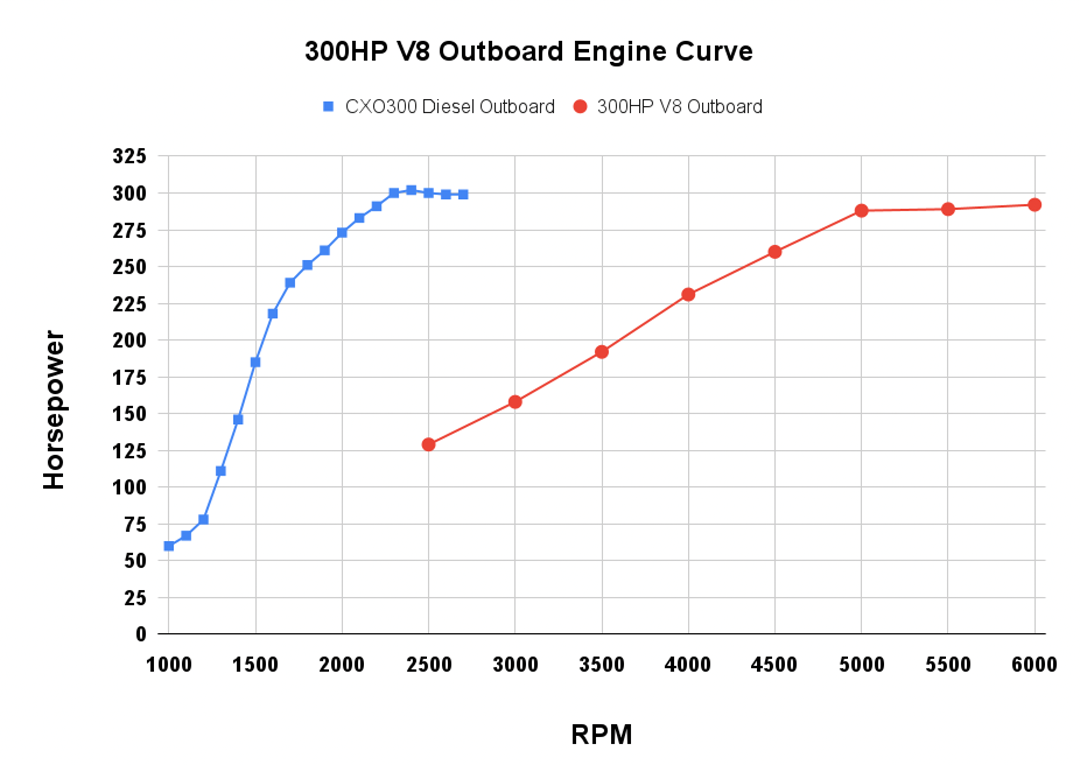

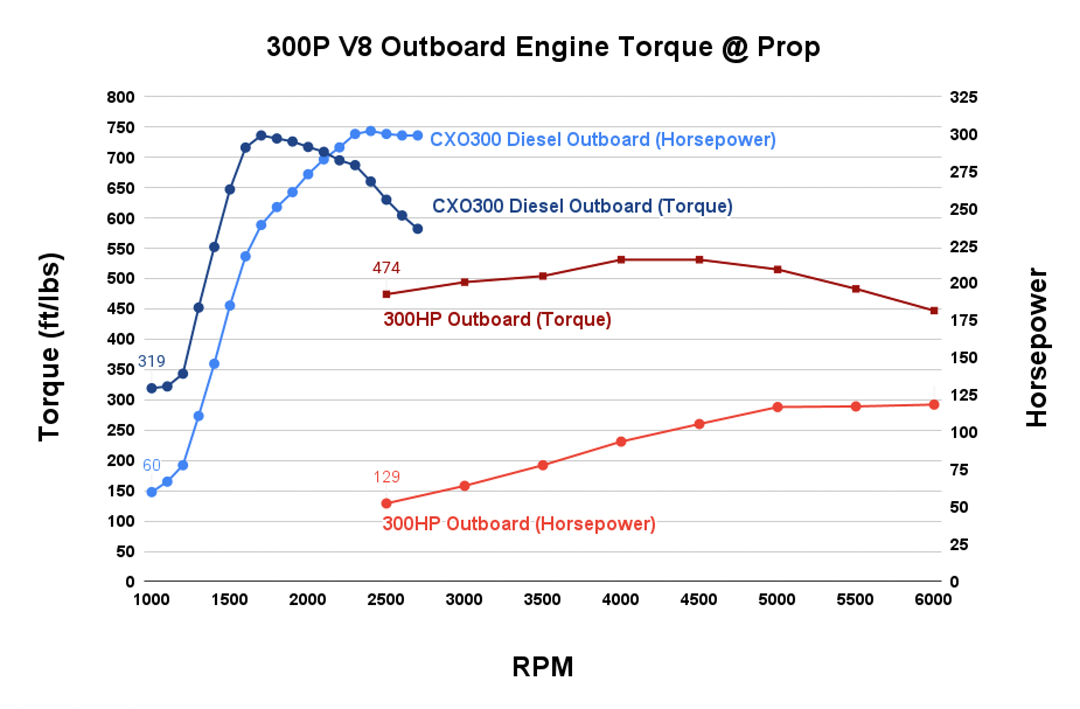

Now, let’s compare the dynamometer derived torque curves of the Cox CXO300 300-hp V8 diesel taken from its EPA certification, and the dynamometer torque readings for a popular 300-hp L6 gas outboard.

The 300-hp gas outboard at 2500 RPM produces 474 ft/lb of torque, going on to a peak output of 531 at 4000 RPM. This is why many of the heavier boats using 300-hp gas outboards don’t get solidly on play until 4000 RPM.

The Cox V8 diesel produces 39% more ft/lb of torque than the gas outboard. This is a dramatic demonstration of what the Cox CXO300 produces and why it so much more powerful than a similar horsepower gas outboard, when getting on plane.

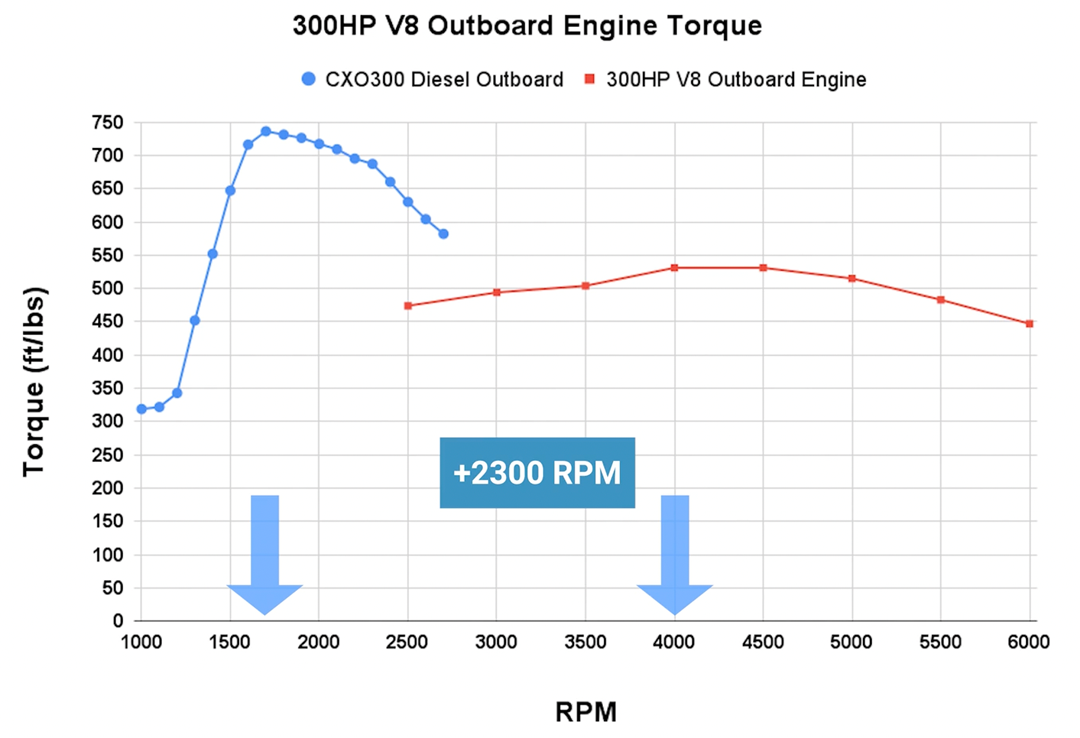

When Does Max Torque Kick In?

Not only is it important what max torque is, but also when it kicks in – as they say, “timing is everything.” Most recreational boat operators want to get on plane as rapidly as possible. In some cases that is because their bows are so high they can’t see forward, and it is a safety issue. Other times it because their boats are loaded with people, that it take a high rev to get over the hump.

That’s why boaters have learned to put the “hammer down” and literally push the throttles to the stops to rapidly spool up the engine in order to create the power to get on plane.

Typically, boats powered by gas outboard engines can’t get on plane until about 3500 PRM, and the heavier ones not until 4000 RPM, depending on horsepower and weight. Comparing the peak torque of both engines above we see that the Cox engine’s peak torque comes 1700 RPM in the dyno test, 2300 RPM before that of the gas engine. Not only does this result in better and safer handling, but it also pays off in the fuel economy of running on plane at a lower RPM with Cox diesel power.

Cox CXO300 Diesel 300 Horsepower

Just as the Cox diesel generates its torque quickly, so too, does it produce its horsepower quickly. As can be seen above, the Cox diesel is generating 150-hp at about 1400 RPM, compared the 300-hp gas outboard that can't muster 150 horsepower until about 3000 RPM.

300 horsepower for the V8 Cox diesel is reached at 2300 RPM, and the L6 gas outboard doesn’t reach nearly 300 horsepower for another 3700 RPM at 6000 RPM. This is a dichotomy that shows that the Cox diesel generates horsepower early when boats need it for lift, and gas outboards develop its max horsepower when it needs it for speed.

By laying both the torque and the horsepower curves for these two types of engines on one graph, we see where and why the Cox diesel develops both high torque and high horsepower where the two blue lines cross. This is at 2200 RPM where the Cox diesel produces 95% of its torque and 97% of its horsepower.

At 2500 RPM the V8 gas outboard is only developing 129-hp, just 43% of what the Cox diesel is putting out, and is only generating 75% of the diesel's torque.

The gas outboard develops its highest horsepower at 6000 rpm.

Reduction Gears Create More Torque

Because gas outboards have relatively weak torque at the crankshaft, they must amplify it at the prop shaft by reducing the RPMs of the drive shaft through gears. Seven of the nine 300-hp gas outboard engines on the market in the U.S. have a gear ratio of 1.75:1. That boosts torque considerably.

But that gain in torque comes at a price. The consequence of increased torque is reduced propeller rotation. When a gas outboard engine with this gear ratio is turning 1000 RPM, the prop shaft is only turning 571 RPM. That means its advance rate is reduced in the sam proportion.

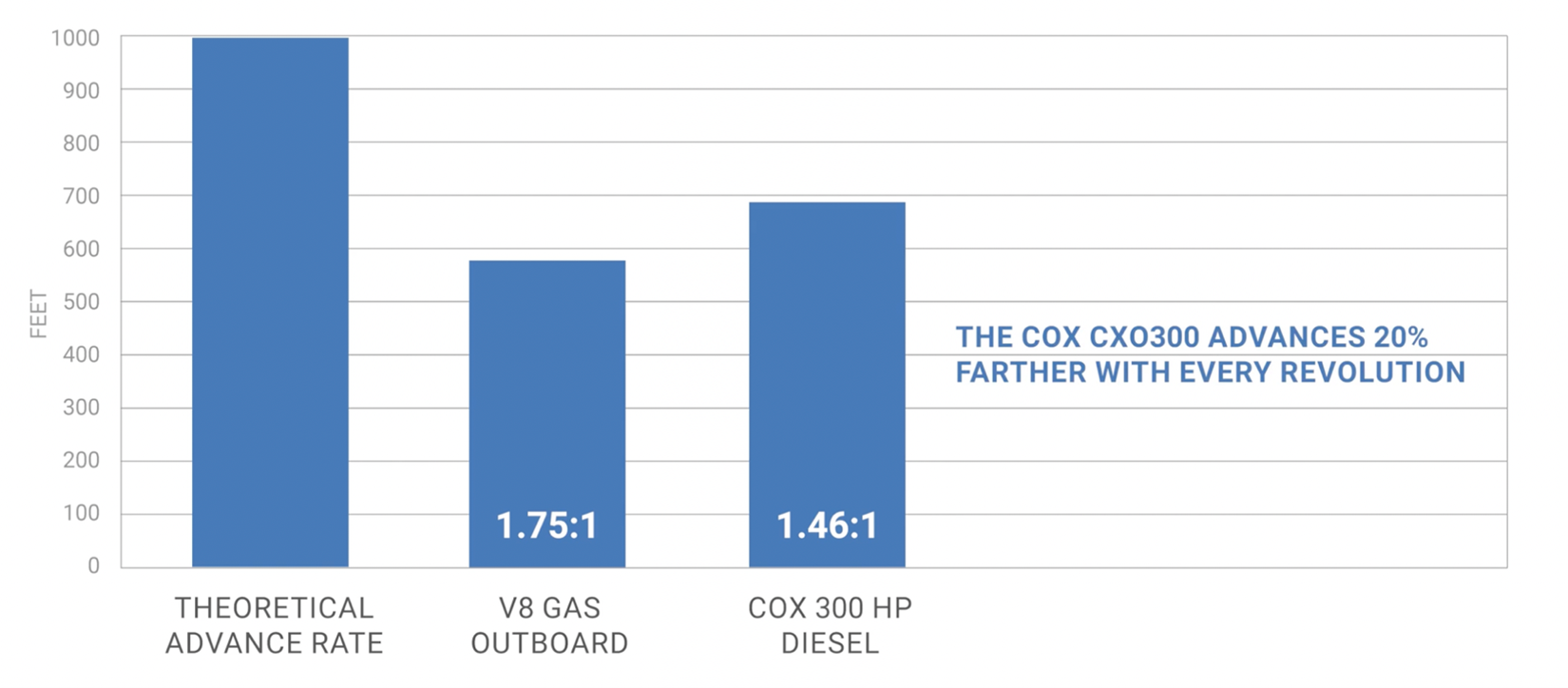

On the other hand, because the Cox CXO diesel’s gear ratio is 1.46:1, its prop shaft is turning 685 times when the engine is turning 1000 RPM -- 20% more revolutions at the prop with the same engine revs.

20% Greater Advance Rate with Cox Diesel

The result is that the theoretical advance rate of a prop on the Cox’s prop shaft is 20% greater than on the gas engine. Theoretically, the boat with the Cox diesel will travel 20% farther on each revolution of the drive shaft. While the slip might be different with both engines, this is another factor contributing to the Cox engine’s great fuel economy.

The Test

Early this spring, BoatTEST was invited to test a Cox CXO300 diesel on a Front Runner 26 Center Console powered by a single Cox CXO300 300-hp diesel. The test weight of the boat was 7,395 lbs. (3,361 kgs.). The engine was fitted by a 16 x 19.5 Mercury Eco prop, which is generally considered to be one of the best props on the market. The ambient temperature during the test was 78F and humidity was 80%.

The chart above shows the numbers we recorded. Note that from 2000 RPM on, we recorded the data every 200 RPM instead of the normal 500 RPM increments as we normally due on gas outboards. The reasons we did this was to more precisely determine performance at different benchmark speeds.

The first thing we noticed was that 6.7 MPH and trolling speed at 1000 RPM we got a remarkable 6.8 statute miles per gallon. That means when offshore anglers can troll all day and use very little fuel.

The second benchmark was at what RPM we got on plane. As can be seen in the chart above (with identical numbers to the numbers at the beginning of this report), the boat got on plane at about 2500 RPM, surging 12 mph in just 200 RPM. This also turned out to be our most economical cruise speed getting 3.3 miles per gallon.

A comfortable cruising speed for this boat was 33.7 MPH at 3000 RPM, where the boat got 2.9 MPG. Top speed was 44.1 MPH at 3800 RPM.

Comparison Numbers

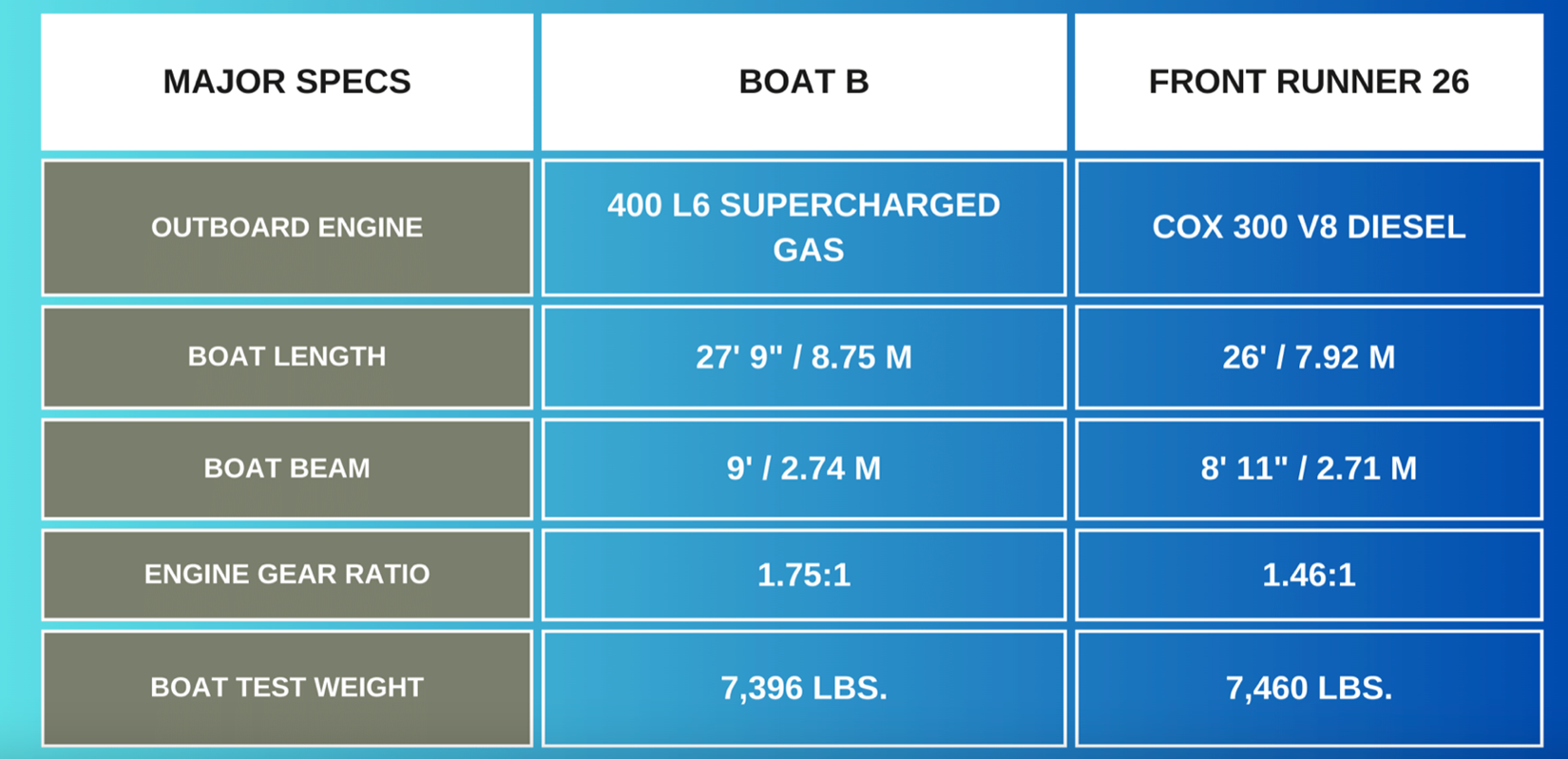

But these speed and fuel consumption numbers don’t mean much in a vacuum. For that reason we searched our data base for boats with a similar displacement, beam and length so that we could get an idea of how the Cox CXO300 measured up to other center consoles on the market. We were looking for a boat powered by a 300-hp gas engine.

Unfortunately, we could not find a 7,000 lb. (3,181 kg.) center console with a single gas engine. The closest we could find was a center console powered by a single, supercharged 400-hp gas engine.

Not Apples-to-apples. They were different boats with different bottoms, one boat weighed 91 lbs. (41 kgs.) more than the other, and one boat had 1” (2.5 cm) less beam. In the big scheme of things, these are not meaningful differences. As far as bottom shape goes, most all boats in class have warped V bottoms these days.

The supercharged L6 gas engine has 2 less cylinders but it has a supercharger to make up for it, and the super-charger gives the engine far better low-end torque than naturally aspirated engines. In fact when we looked around at other boats and gas engine combinations, we could not find one in this size and type that beat the Cox CXO300’s relatively high MPG numbers.

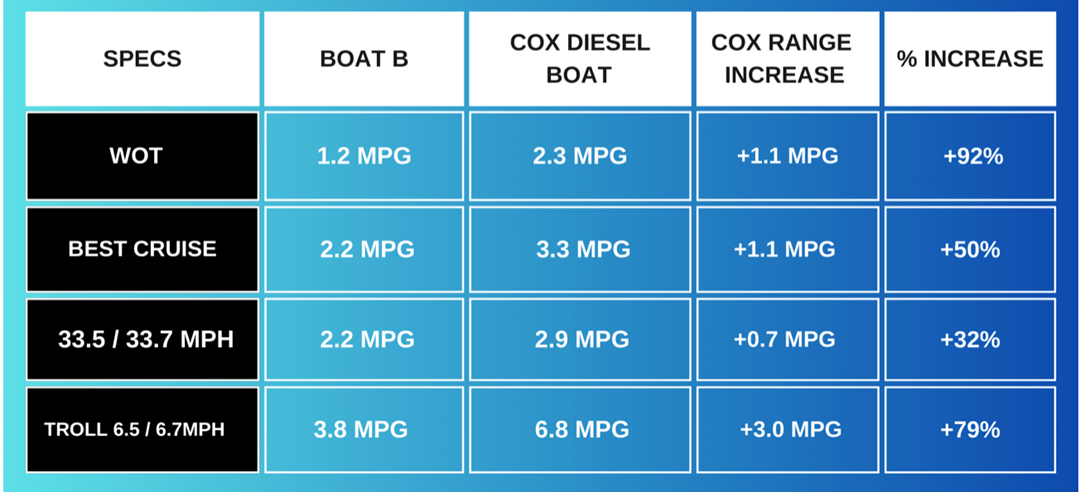

Performance Comparison

When we compare top-end speeds between the Front Runner and Boat B, we see that the latter went 47.4 mph, just 3.3 mph faster than the one propelled by the Cox 300-hp diesel. The Front Runner went 7% slower at top end, but of course no one drives their boat at WOT for more than a few minutes, no matter what the power. So, this is not a particularly meaningful number.

More important are the data shown below, where we compare the Miles Per Gallon (MPG) for the two boats. Note that while the gas outboard is a little faster it does it a great fuel cost, getting just 1.2 MPG compared to 2.3 MPG for the Cox driven boat. The Cox’s fuel consumption at WOT is 92% better.

Best Cruise is the most important number on any performance test, and here we see that the gas engine delivered 2.2 mph and at 3.3 mpg the diesel powered boat got 1.1 MPG more, or a 50% improvement. This is why diesels engines start paying for themselves from the first mile driven.

Best cruise speed for the Front Runner was 26.7 mph, and it was 33.5 mph for Boat B.

Driving to the Canyons. Many boaters going offshore in center consoles like to travel in the mid to low 30s, because it is a good balance of time taken to get to a destination and fuel consumption. When we compare the two engines’ performance at about 33 mph – 33.5 for Boat B and 33.7 for the Front Runner – we see that here also the Cox engine out-performs the gas engine in terms of MPG, being 32% better.

One of the reasons for that thirsty fuel consumption at 33.5 MPH by the 300-hp gas outboard was the fact that it was turning 5000 RPM. At the same speed, the Cox engine was looping along at 3000 RPM.

At the same speed. While diesel engines have a reputation for not being as fast as gas outboards, at realistic speeds where boats will actually run – 25 mph to 40 mph – the Cox diesel-driven boat can go just as fast and do it significantly more economically.

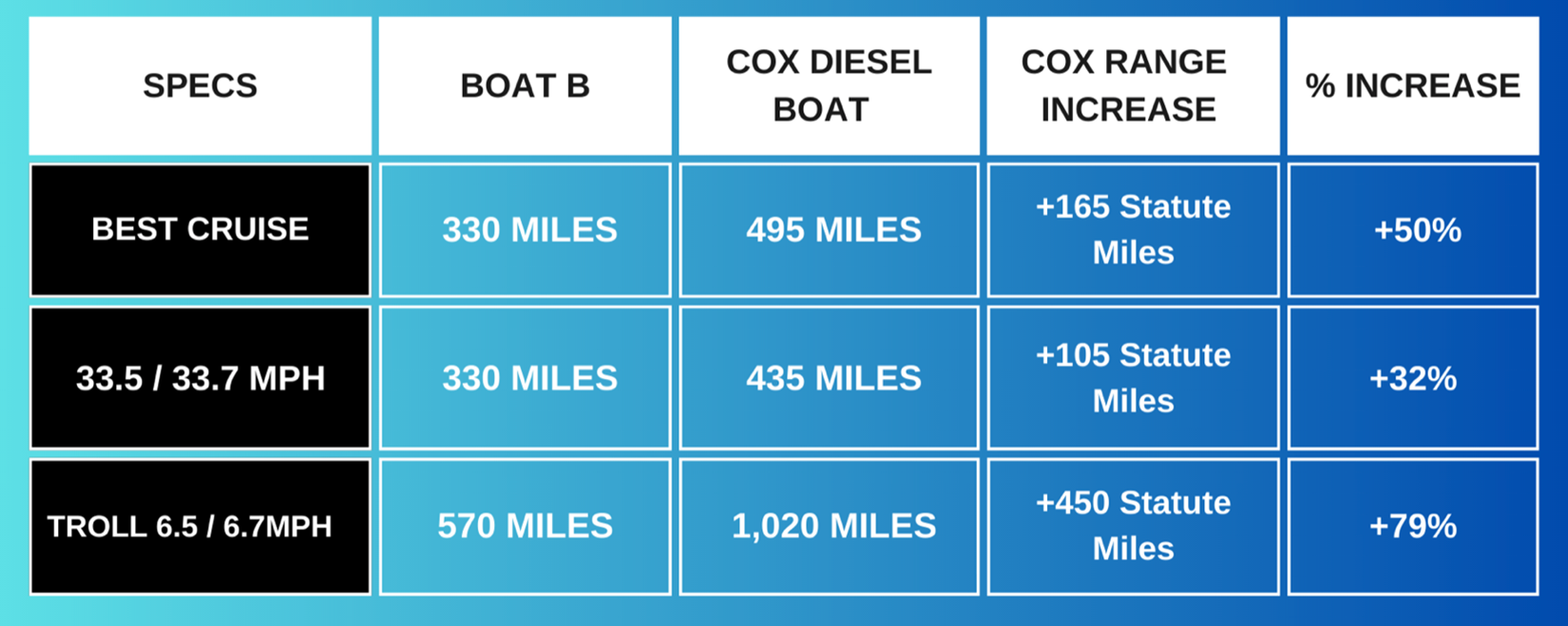

What do these numbers mean? They all have to do with the with the relationship of the boat’s fuel capacity, speed and fuel burn. In the chart above we have assumed that both Boat B and the Front Runner have a fuel capacity of 150 gallons, which is typical for center consoles in this class. To keep things simple, we have not calculated a 10% fuel reserve, but rather 100% available.

As can be seen in the chart, the Cox engine not only gets the best fuel mileage by 50% at best cruise, but also at 33 mph, it does 32% better.

Once to the fishing grounds, with the Cox diesel a boat can troll all day long, and not burn much fuel, and 79% less than the gas engine.

Real World Context

In order to graphically demonstrate the import of the remarkable fuel efficiency of the Cox engine, we have plotted out on the map above how far the Front Runner can go: From Miami to Nassau and back to Miami by way of Bimini, is 378 statute miles, then 57 miles down to the Ocean Reef Club on Key Largo, before having to refuel. 435 statute miles on one tank of fuel.

On the other hand, Boat B will only be able to travel to Nassau and back to Bimini but only have 6 gallons of fuel in his tank -- not enough to make it across the Gulf Stream. Boat B will have to refuel in Bimini. Bimini is a nice place to visit, and while filling up there, the boat’s operator might have time to go see the sights and get some fresh-baked bread.

Oh, have we told you about diesel prices in Bimini? Would believe $10 per gallon. Is it even available? Another good thing about diesel engines for those with trailerable boats – you don’t have buy diesel fuel at a marina, you can get it for a big savings at a truck stop.

Observations

Americans’ obsession with speed is costly –both in terms of the cost of engines, and the fuel they burn. Our take away from this test and the whole exercise is that while the Cox CXO300 diesel might not be the fastest outboard on the planet, it can propel a boat fast enough, and that’s where most boats’ operators run their boats anyway.

There is no doubt that as boat builders make larger and heaver boats, they will be looking to diesel outboards for the torque to get their boats on plane at lower RPM. There is now a good alternative to hanging a lot of iron on the transom.