Access More Boat Tests

Already have an account? Login

Hatteras GT65 Carolina (2020-)

Brief Summary

The Hatteras GT65 Carolina is the newest offshore battlewagon from the legendary builder of bluewater big-game fishing boats. She has a sleeker profile than her predecessor, the GT63 and features a larger cockpit. Belowdecks the GT65 Carolina’s four staterooms and three heads take advantage of the boat’s additional volume.

Specifications

| Length Overall |

65' 2'' 19.86 m |

|---|---|

| Beam |

20' 0'' 6.10 m |

| Dry Weight |

103,000 lbs. 46,270 kg |

| Draft |

5' 0'' 1.53 m |

| Fuel Capacity |

1,900 gal. 7,192 L |

| Water Capacity |

270 gal. 1,022 L |

Engine Options

| Std. Power |

2 x 1600-hp CAT C-32A diesel engines |

|---|

by Capt. Martin Frobisher

Mission Statement

Hatteras has built its reputation by manufacturing legendary bluewater fishing machines. The GT65 Carolina is the first boat in the company’s new GT Series and it combines serious offshore capabilities with the luxury and accommodations that discerning captains and crew look for during an offshore fishing adventure.

Features Inspection

The Flybridge. Let’s start at the top and work our way down. The new flybridge has an ergonomically designed console that puts all of the controls in convenient reach. It incorporates the latest in navigation and fishfinding electronics in a glare-reducing, flush-mounted “glass cockpit” array. The captain can be joined by a companion in the dual helm seats and there are lounges on each side and on the front of the console. A stainless-steel rail extends across the aft end and it’s equipped with rocket-launcher-style rod holders. One of the screens at the upper helm is for the Hatt/CON system. It controls all of the boat’s systems and monitors everything from a single location and the program can be downloaded to the owner’s/captain’s mobile phone or computer. A stainless-steel ladder to starboard leads up to the fish-spotting tower or down to the GT65 Carolina’s cockpit.

The Cockpit. Heading down the ladder, the GT65 Carolina’s cockpit has 182 square feet (16.91 square meters) of fish-fighting space. The mezzanine seat to starboard can have optional integrated seatback air conditioning and there are large stainless-steel built-in storage boxes. There’s a galley starboard and twin passageways lead forward to the wide-open bow. For added comfort, twin Seakeeper 9 gyroscopic stabilizers are available and hatches in the cockpit deck provide access to the engine compartment.

The Salon. Three steps lead up to the entry to the GT65 Carolina’s salon. Aft to port, an L-shaped lounge wraps around a table and forward is a U-shaped dinette. To starboard there’s a TV in an entertainment cabinet that also has storage. For casual dining, owners can choose between an island-style bar with two stools or one that extends outboard to starboard with three stools and more counter space.

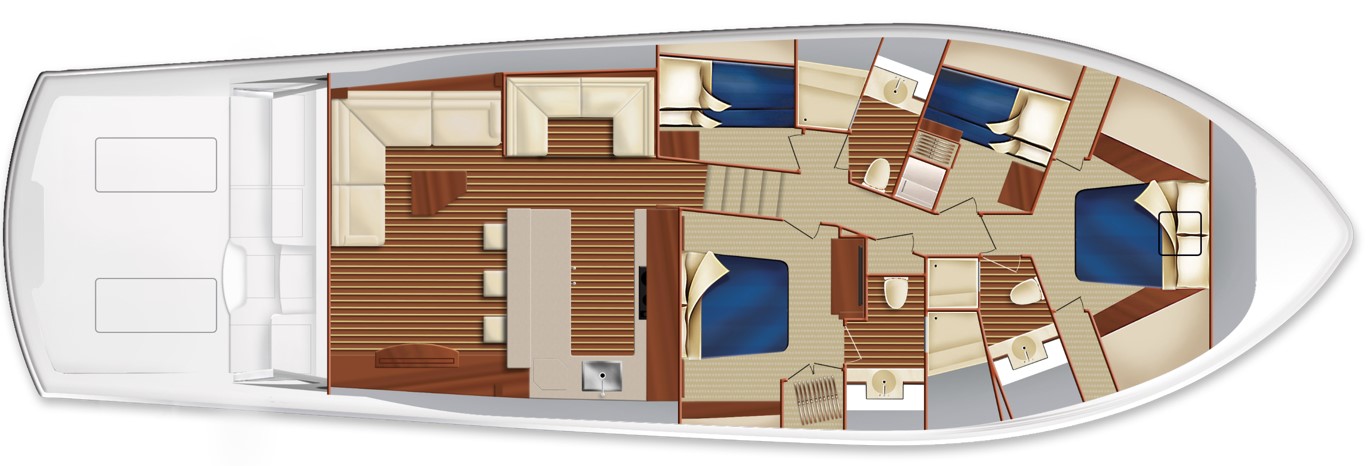

Belowdecks. Between the galley and dinette, stairs lead to the GT65 Carolina’s accommodations deck. Immediately aft to starboard is the master stateroom that has the berth just to starboard of the centerline. There’s a TV across from the foot of the berth and to starboard is a full-height handing locker with entry to the ensuite head forward. Head to the bow, where the VIP cabin has a traditional island berth with raised steps on each side. There are lockers on each side of the aft end of the cabin with entry to the ensuite head aft to starboard. Abaft the VIP cabin to port are two more cabins with bunk-style berths. The day head is between the two cabins and all the heads have shower stalls.

Updated Construction. Hatteras builds the GT65 Carolina’s hull and superstructure in two separate parts that travel down the line next to each other. The company uses a process called integrated infusion. The longitudinal stringers are made of cross-link PVC foam and are resin-infused at the same time as the hull, creating a single unit. The high-tech method saves weight and adds strength.

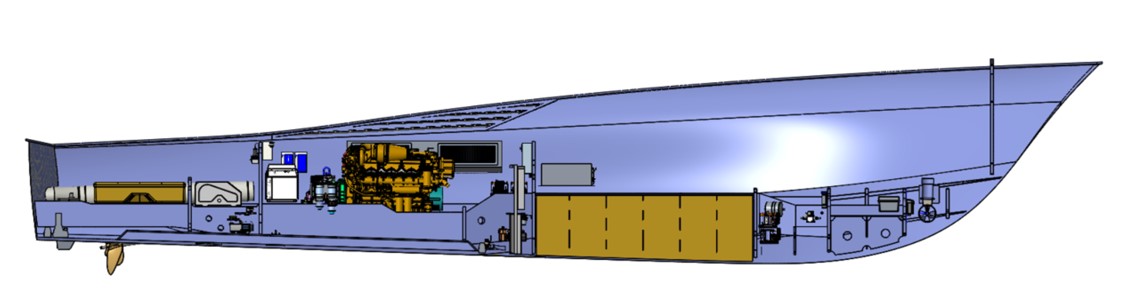

After the hull is removed from the mold, the boat’s twin Caterpillar diesel engines are installed. Standard power is twin 1600-hp C-32As, but owners can update to twin 1800-hp or twin 1900-hp engines. Hatteras employees also installed the plumbing, electrical wiring, furnishings, and components.

Next, the superstructure is lifted by a crane and lowered onto the hull with the upper part overlapping the lower in a shoebox-lid fit. The two pieces are fastened in a four-part process with adhesive caulking, fiberglass, Monel screws every 3” and a 316L stainless-steel rubrail.

Painstaking Painting. One of the last stops a boat being built at the Hatteras facility in New Bern, N.C., is the paint shop. The finishing process involves 10 steps using six different materials and can take as many as 20 workers and more than 10 days to complete. The first step is to dewax the hull by stripping and sanding away the gelcoat. Surfaces are coated with a blue dye that helps identify high or low spots. Protective coatings come next. They help prevent blistering and withstand the rigors of the offshore environment. Below the waterline, two layers of epoxy barrier coat are applied along with two coats of anti-fouling paint. Above the waterline, the GT65 Carolina receives three applications of polyurethane topcoat. In between coats, the employees sand the surfaces by hand, which can take many days. The superstructure receives the same treatment and extra time is spent around the windows and doors.

An owner can choose custom paint above the waterline. The first GT65 Carolina, Fish Tank, is done in a shade of blue gray and the paint contains a UV coating to help protect the color and finish from the sun.

Design

The Bottom. The Hatteras engineering team used advanced technology to develop the GT65 Carolina’s hull bottom. “The design goals for the GT65 Carolina were greater speed, improved efficiency, better fuel economy and a smoother ride,” Glenn L. Spain, mechanical engineering manager for Hatteras/Cabo Yachts. The team used computational fluid dynamics and finite element analysis to test and refine concepts for the boat’s new hull bottom.

“We create a digital model of the hull in the computer. We locate the center of gravity, weight of the boat and the desired speed,” said Spain. “The program iterates the calculations for power required until the result converges. This takes approximately 23 hours per data point. We ran dozens of data points to establish the ideal design and for weight and LCG.”

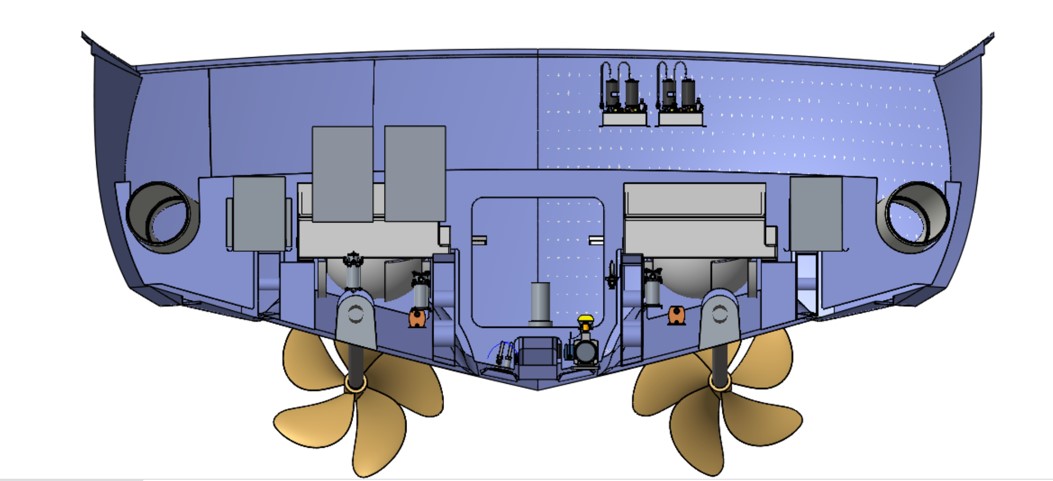

An evolution of the GT Series, the GT65 Carolina’s propriety bottom form features a new design for the propeller tunnels. “We reviewed and redesigned the propeller tunnel entry design to improve water flow into the propeller, providing more thrust per horsepower,” said Spain. The new hull is designed to get owners to the fishing grounds or to their next boating adventure at a faster cruise in the mid-30-knot range and achieve a top end that exceeds 40 knots.

The hull is also designed to accommodate twin Seakeeper 9 gyro stabilizers without compromising fuel capacity or range. They provide additional comfort.

Observations

If pedigree is anything to go by, the GT65 Carolina will be the epitome of the offshore battlewagon with even more refinements. The improved construction that enhances strength and saves weight combined with new bottom design should help keep the signature Hatteras ride and give the boat even more range than the GT63.

The luxury and appointments are what we’ve come to expect from Hatteras and we will update our report after we see the boat.