Both Parties Shuck Corn Ethanol -- No Longer PC

Corn

ethanol is no longer the yellow brick

road to U.S. energy independence. It seems that the silk is off the corn ear, as

it were. Both political parties have inserted a nearly identical

sentence into their party platforms which has them slip-sliding away from corn ethanol – and moving toward cellulosic ethanol. The powerful farm

lobby is clamoring for more E85-capable engines from Detroit.

|

|

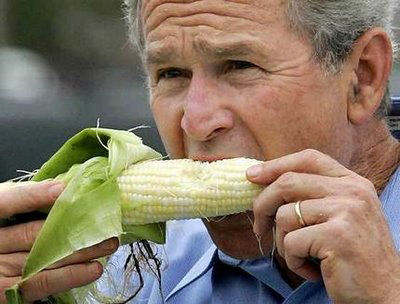

“Let them eat corn!” says the Republican Party and drops corn ethanol from its platform. (Oh, Dubya, that's raw corn you're eating.) |

While listening to Gov. Sarah Palin's VP acceptance speech last week our ears perked

up when we realized that her laundry list of alternative energies did not include

the word "ethanol." Upon checking the Republican Platform, we discovered a line

that said: "We must continue to develop alternative fuels, such as bio fuels, especially

cellulistic ethanol..."

We then turned to the Democratic Platform and found a nearly identical pronouncement:

"We'll invest in advanced biofuels, like cellulosic ethanol..."

You say Tomato, I say…

Now, is it "cellulistic" or "cellulosic"? Dictionary.com did not have a listing

for "cellulistic" and asked if we meant "cellulosic." Ah, the dictionary reads minds

as well as giving definitions. "Cel-lu-lo-sic -- adjective; 1. of, containing, or

derived from cellulose."

What all of this means, we suspect, is that the hue and cry that has gone up about

taking corn from the starving mouths in Bangladesh has turned corn ethanol into

the fuel of darkness. It is no longer politically correct.

|

America's first cellulosic refinery opened last month in Butte, Montana. |

Flavor of the Month

As it turns out, the very first cellulosic refinery in America opened just last month

in

Butte Montana.

This refinery hopes to produce 100 million gallons annually --

a drop in the bucket compared to the 10 billion gallons of corn ethanol which will

be refined this year. The DOE recently approved six

cellulosic refining plants for $350 million in start-up grants.

Cellulosic ethanol is more problematical and costly than corn ethanol, which in

turn is more costly than making ethanol from sugar cane, as the Brazilians do. The

cellulosic refineries cost five times more than corn refineries, and are less efficient.

The good news is that they can refine cellulose from virtually any plant, which

means that most anything that grows, such as wheat stalks, underbrush, wood chips,

switchgrass and corn cobs -- among hundreds of other things which are considered waste -- can be refined into cellulosic ethanol without hurting

the food supply.

A side benefit is that refining cellulosic ethanol produces fewer greenhouse gasses than

does refining corn, we’re told.

|

Move over Arab Sheiks, Midwestern farmers are tomorrow's megayacht owners. |

Push for E85 comes in 2014

According to U.S. Department of Energy, "... the U.S. market for E10 is saturated

by 2014, after which the ethanol requirement is met by increased consumption of

E85. To encourage the use of E85, its price is discounted to make it competitive

with motor gasoline on an energy-equivalent basis. The E85 price discounts are funded

by premiums placed on the petroleum content of other motor fuels…”

Where all of this leaves the American boater is not clear. Both inboard and stern drive gas engines come from GM blocks, and GM is very much

in the E85 business and has several models on the road which account for 1.5 million E85-capable vehicles.

Indeed, GM

has recently invested in a new cellulosic refinery outside of Chicago.

Under one scenario, as ethanol refineries are able to produce more ethanol, the

DOE will raise the blend requirement in gasoline. Clearly, in 2014, or before, there

will be a showdown between ethanol proponents and the naysayers.

E10 “Trip Wire” for Marine Engines

The NMMA “government relations” staff was able to get an important stipulation inserted

into the federal energy bill signed into law by President Bush in December, 2007.

This little-known provision requires that before any requirement that boats use

an ethanol blend higher than E10, that an approval process be followed that will

entail hearings and data collection that will satisfy the EPA that “mid-level ethanol

fuels” will not damage marine engines, boat fuel systems or components.

The NMMA says, “Boat engines are not designed or calibrated to run above E10, and

higher concentrations of ethanol can cause damage to marine engines and fuel systems,

and potentially cause emission control devices required by federal law to fail.”

Some industry observers think that this provision will exempt recreational marine

engines from higher ethanol blends for the foreseeable future.

What’s Wrong with Ethanol?

Leaving aside political considerations, the fact that it is more expensive than

gasoline, and will indirectly (if not directly) raise food prices at least in the

short run – what is wrong with high blends of ethanol in marine engines?

In marine engines ethanol causes a number of problems, including 1) higher heat,

2) corrosion, 3) water separation problems, 4) lower efficiency.

1. Higher Heat. Ethanol contains about 3% oxygen which makes it

burn hotter than a like amount of gasoline. This oxygen becomes 3/10ths of a percent

in an E10 blend, which is negligible. At E85 the oxygen ratio rises to 2.55%, making

combustion hotter which – according to marine industry sources – can burn out head

gaskets, valves, piston rings and pistons or substantially reduce the engine’s useful

life. All of these components can be made to withstand higher heat, but at what

cost?

2. Alcohol is corrosive. Rubber gaskets, hoses, fittings in the

fuel lines, and certain plastics are susceptible to degradation from alcohol, to

say nothing of old fiberglass fuel tanks turning to mush. Higher levels of ethanol

are more corrosive, requiring higher quality and more expensive materials.

|

|

This is an example of phase separation which appears on the Mercury Marine website. Ethanol is in the top strata, and water mixed with ethanol is the bottom, darker layer. |

3. Alcohol absorbs water. Water which comes from the atmosphere,

in time, can contaminate the fuel, then separate from the alcohol (called phase separation)

which can be problematical. Mercury Marine on its website says that “there is no

practical additive that can prevent phase separation.” Several additives on the

market today claim to be a solution to phase separation, but have not produced 3rd-party

testing results to the satisfaction of BoatTEST.com. During the season, fuel tanks

should be kept full to reduce condensation in the tank. In the winter, the tank

should be emptied. If it can not be emptied, it should be filled and a fuel stabilizer

should be used in the proper dosage.

4. Lower efficiency. A unit of 100% ethanol has about 34% less

energy (lower BTUs) than the same unit of gasoline. This translates less power and

lower efficiency, all things being equal. An E10 blend has 3% lower efficiency;

therefore the fuel economy is 3% less. With E85 it will be about 30% less.

Other than that, how did you like the play, Mrs. Lincoln?

Your Comments Please…