Are All Bass Boats The Same?

See commercial video of a pultrusion machine in action

Are all bass boats getting to

be the same? Certainly every good new idea gets copied by all the major builders

by the next boat show. Virtually all bass boats are low, flat, sleek, full of

rod and tackle lockers, and with decks covered with what appears to be the same

gray carpet. So what is left to really differentiate the boats besides the hull

graphics? The answer is: the differentiation is in the details. Bass boat

builders actually put as much, if not more, work into perfecting the fine points

of bass boats than any other type boat, foot-for-foot. These builders hone,

polish, and improve everything they can think of – and many of these details

unfortunately can’t be seen. The best example we can think of is Ranger Boats'

use of pultrusions. It sounds like a dirty word, you can’t see them, and they’re

as strong as steel. Why does Ranger use them? What do they do?

|

||||

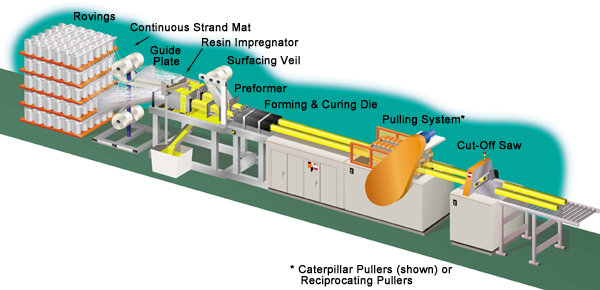

Pultrusions are made with unidirectional glass fiber, then mat with a special resin, all pulled and heated into a flat plate that is sawed off in different lengths. |

In one of Capt. Rob Smith’s video boat tests he says that all bass

boats look pretty much the same. We agree. But just because they look the same,

doesn’t mean they are the same. When we toured the Ranger factory we were

introduced to the first pultrusion machine that we had ever seen in the boat

business.

Pull What?

What is a pultrusion? Wikipedia says: “Pultrusion is a continuous process of

manufacturing of composite materials with constant cross-section whereby

reinforced fibers are pulled through a resin, possibly followed by a separate

preforming system, and into a heated die, where the resin undergoes

polymerization.”

|

Drawing of pultrusion machine that shows the different stages. |

The word pultrusion is a made-up word, combining “pull” and “extrusion” which

does a good job of describing what is going on. Ranger’s pultrusion machine

pulls the glass fibers and mat through a special resin bath, then through a

super-heated die that instantly cooks the resin and produces what is a long,

relatively thin extrusion that is sawed off in desired lengths.

Strong as Steel --

After the gray pultrusions coming out of the end of the machine cool, they are

like steel plates, only lighter. Pound for pound, they are stronger than

structural steel and 25% of the weight. And they don’t rot or soak up water or

anything else unpleasant that standard boat building coring or deck-stiffening

material might do.

And, that is how Ranger uses their pultrusions – as coring material. First, and

most importantly, it is used in the transom of all Ranger boats, providing

rigidity and strength precisely in the area that has to support the weight,

torque and power of huge outboard engines.

|

Actual picture of a pultrusion machine taken from the Internet. |

Secondly, other pultrusions of many different sizes are used all over the deck

for stiffening and strength. Forget about plywood, balsa core, and closed cell

foam. Ranger is glassing in what amounts to steel plates any place on the deck

where the fiberglass might be stressed or flex. On one boat, I counted over 25

pultrusions spotted all over the boat in critical locations.

So, all boats aren’t the same. You just have to look at the details.

To see all Ranger Boats tests --