Jet Drives Picking Up Steam in Many Applications

The advantages of jet drives have been obvious for years, but recently they have picked up in popularity. This has happened in large part because of their success in PWCs built by several companies, and in jet-powered runabouts built by Yamaha and Sea-Doo. In fact, the 23-foot Yamaha runabout is the largest selling boat that size in the U.S. Maine boat builder Hinckley has been installing them for over 10 years in its picnic boat series, Huckins has installed them in its new 56-foot boats, and last year they were even put in a new U.S. warship complete with joystick steering. They are adaptable to virtually all types of engines from outboards to large diesels.

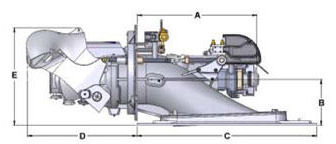

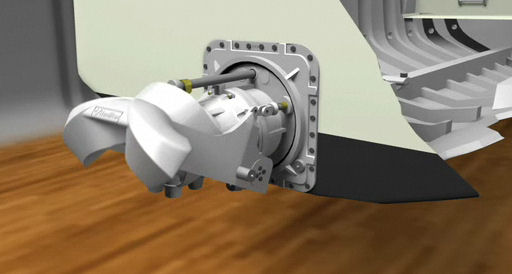

Drawing of a Hamilton jet unit. Hamilton has been making jet drives since 1954.

Water jet propulsion has many advantages over other forms of marine propulsion, such as stern drives, outboard motors, shafted propellers and surface drives. These advantages include...

Excellent Maneuverability

• Precise steering control at all boat speeds

• "Zero Speed" steering effect provides 360° thrusting ability for docking and holding stationary.

• Sideways movement possible with multiple jet installations.

• High efficiency astern thrust with "power-braking" ability at speed

High Efficiency

• Propulsive coefficients as good or higher than the best propeller systems achievable at medium to high planing speeds

• Hole shots faster than prop-driven boats

• Better fuel efficiency than most other propulsion options

Low Drag and Shallow Draught

• Absence of underwater appendages reduces hull resistance

• Shallow draught - the water jet intake is flush with hull bottom to allow access to shallow water areas and beach landings with no risk of damage to the drive

• Ideal for skinny, rocky rivers

Low Maintenance

• No protruding propulsion gear eliminates impact damage or snags

• Minimum downtime and simple maintenance routines

• No worries about bent shafts or struts

• No cutlass bearings to be replaced

• No stuffing box or rudder shaft leaks

Smooth and Quiet

• No hull vibration, no torque effect and no high speed cavitation

• Low underwater acoustic signature

Safety Factor

• No exposed propeller means safer environment for swimmers and animals

• Warning: Jet thrust can be dangerous

Maximum Engine Life

• Jet unit impeller is finely matched to engine power

• Power absorption is the same regardless of boat speed

• No possibility of engine overload under any conditions

Simplicity

• Single packaged module

• No heavy and expensive gearbox required for many installations. Simple driveline from engine to jet coupling

How a Water Jet Works

A water jet generates propulsive thrust from the reaction created when water is forced in a rearward direction. It works in relation to Newton's Third Law of Motion - "every action has an equal and opposite reaction". A good example of this is the recoil felt on the shoulder when firing a rifle or the thrust felt when holding a powerful fire hose.

Put simply, the discharge of a high velocity jet stream generates a reaction force in the opposite direction, which is transferred through the body of the jet unit to the craft's hull, propelling it forward.

In a boat hull the jet unit is mounted inboard in the aft section. Water enters the jet unit intake on the bottom of the boat, at boat speed, and is accelerated through the jet unit and discharged through the transom at a high velocity.

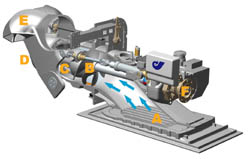

The picture shows where water enters the jet unit via the Intake (A). The pumping unit, which includes the Impeller (B) and Stator (C), increases the pressure, or "head", of the flow. This high pressure flow is discharged at the nozzle (D) as a high velocity jet stream. The driveshaft attaches at the coupling (F) to turn the impeller.

Steering is achieved by changing the direction of the stream of water as it leaves the jet unit. Pointing the jet stream one way forces the stern of the boat in the opposite direction which puts the vessel into a turn.

Reverse is achieved by lowering an astern deflector (E) into the jet stream after it leaves the nozzle. This reverses the direction of the force generated by the jet stream, forward and down, to keep the boat stationary or propel it in the astern direction.

Installation is Easy

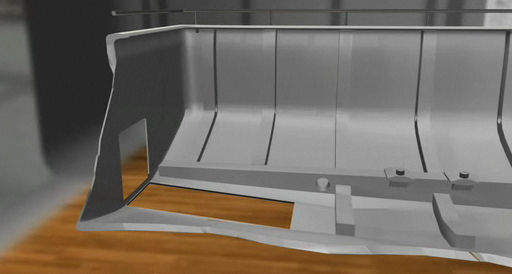

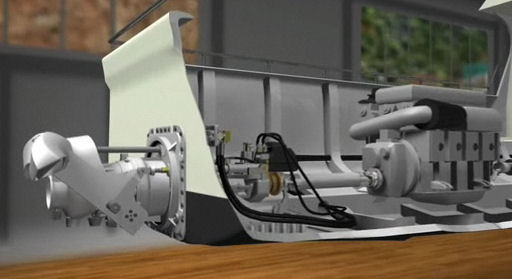

This is a cut-away drawing of the stern sections of a conventional boat.

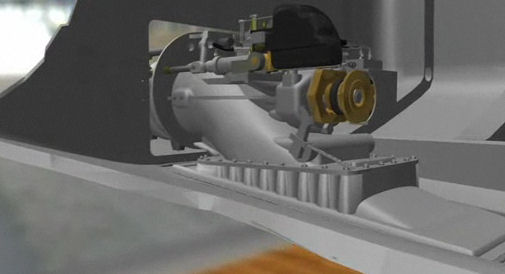

The water intake plate is fitted to the boat’s bottom and the unit is installed.

The transom plate is bolted over the jet drive nozzle and gasket.

Finally the engine is connected to the impeller drive shaft. In this example a jack shaft is used to connect the engine with the jet drive unit.

Drawings and some material courtesy of Hamilton Jet.

See Capt. John Wenz explain how Yamaha jet drives work --

See outboard engine jet drive video by Yamaha --