A Seacock is Your Most Important Gear

Last fall, one of our test captains discovered a gate valve installed on a new offshore fishing boat built by a famous name. We were appalled! Gate valves are essentially what you have behind your house for the garden hose. Good boat builders stopped using them in the 1950s and ‘60s. The ABYC forbids them in all NMMA-certified boats, and frankly we thought they were a thing of the past until our discovery last fall. (You won’t see that boat builder here!) Seacocks must be not only marine-grade ball valves but they must also be installed properly. They are the single most important item on your boat.

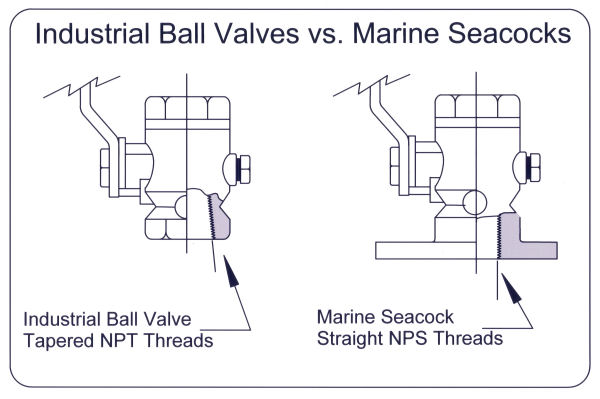

Drawings of industrial ball valve and a marine ball valve seacock.

From thevirtualboatyard.com--

One of the comments I often hear at the boatyard is, “This seacock is too expensive, I can get the same thing at a home improvement store much cheaper.” Well, yes, you can find something there that looks a lot like a seacock, or more correctly a ball valve, but it isn’t the same.

The American Boat and Yacht Council (ABYC) has established standards for marine seacocks. One of the most critical is that the seacock withstand a 500-pound load applied to it for a period of 30-seconds. ABYC also requires a handle that swings through a 90-degree arc and that the handle indicates whether the seacock is open or closed.

The most common style of seacock is flanged. This type has the flange bolted to the hull and the thru-hull threaded into the base of the seacock. This design makes a very sturdy installation. They are also only available as marine products as buildings don’t use them.

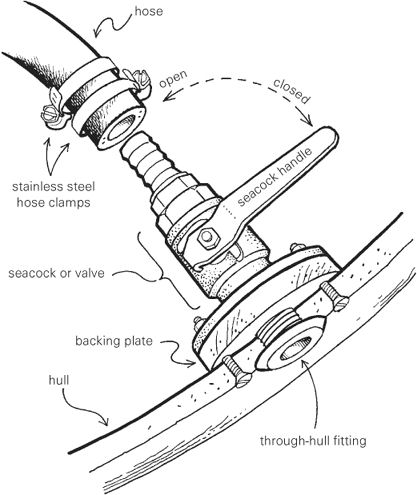

This drawing shows the proper installation of a ball valve seacock. We would add some sealant.

Another type often used as a seacock is a ball valve threaded onto the thru-hull. The thru-hull is fastened to the mounting pad and hull by a large nut on the inside of the boat. The ball valve is then threaded onto the end of the thru-hull and the hose bard is screwed onto the other end of the valve. A couple of turns of Teflon plumber’s tape seals the threaded connection.

The Important Difference

Now comes the important part. There are major differences between the $10.98 home improvement store or industrial ball valve and the $69.49 flanged marine seacock. First, most of the industrial ball valves are brass, not bronze. Saltwater, in contact with brass, leaches the zinc out of the brass, leaving a soft, spongy, reddish copper ball valve that is structurally weak.

Many other parts of these valves are carbon steel, and subject to rapid rusting in the harsh marine environment. The balls may or may not be chromed bronze or stainless steel.

Only use proper marine seacocks sold by marine supply stores – they know what you need.

However, the most critical problem is the design of the valve itself. An industrial-style ball valve has an NPT pipe threaded openings on each end. These accept any number of standard plumbing fittings that have tapered pipe threads. Tapered threads get progressively tighter as you screw them together, fine for home plumbing.

Marine seacocks, on the other hand, have the top end with an NPT (tapered thread) and the flanged end with an NPS straight pipe thread. These threads match the straight pipe threads on the thru-hull.

A Job for the Boatyard

The problem arises when someone tries to screw a ball valve with the tapered NPT threads onto a thru-hull with NPS straight threads. You can get three or four threads engaged before the ball valve tightens up on the thru-hull. If Teflon plumber’s tape was used, it probably won’t leak. However, it won’t stand up to the required load test and is a potential catastrophe waiting to happen.

One day, when you go to turn the handle, the ball valve may come off in your hand, leaving a rather large hole in the bottom of your boat. Just to give you some perspective, a three-finger sized hole near the waterline will let in over 4500 gallons of water per hour. Think your 360 GPH bilge pump will handle that?

Therefore, the moral of this story is that you DO get what you pay for, at least sometimes. Face the situation and get the marine-rated part, especially below the waterline. And have a reputable boatyard install it for you.

Be prepared for thru-hull emergencies with wooden plugs.

Just as an additional safety note; invest in a set of those wooden tapered plugs you see hanging in the plumbing aisle of your marine store. Screw a small eye in the top of each one and tie the appropriate size plug to the thru-hull. Keep a hammer where you can find it and make sure you have room to use it. While your thru-hull may be marine-rated and strong enough, the hose could also fail. Having the plug ready to drive into the resulting hole might well save your boat.

Article reprinted from thevirtualboatyard.com…