What You Need to Know About Turbochargers

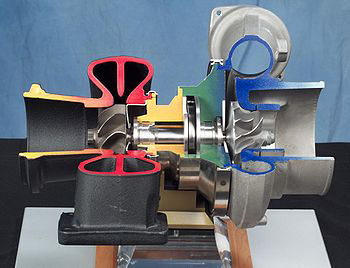

Turbochargers are a simple, elegant concept: use an engine’s exhaust gases to spin a turbine to compress air to pack more oxygen in cylinders for greater horsepower. Today, virtually all marine diesels have them because of the advantageous power-to-weight ratio they provide. While your engine is turning a 2000 rpms, they may be spinning as fast as 100,000 rpms, yet they usually give no trouble and require little maintenance. Nevertheless, they are delicate, precision-made items of equipment with extremely close tolerances and they can be easily rendered inoperable in the right circumstances. As our story this week about a boat fire illustrates, the more you know about maintaining one, the better.

First patented in 1905 Swiss Alfred Buchi, the turbocharger was used first on ships’ diesel. The first truck engine turbo was made by Switzer in 1938. |

The following material is courtesy of Lubrication Engineers, Inc. It has been edited for length and appropriateness for marine applications--

The intake of foreign material into the compressor or turbine wheels; high exhaust temperatures; and improper lubrication are the three most generally recurring reasons for turbocharger failure.

Cut away of a turbo with the exhaust on the left which turns the blades which turn a shaft connected to the compressor blades on the right which “compresses” the air and sends on to the intake manifold. |

Proper Lubrication

Failures related to faulty lubrication cover everything from low-quality oil being used in the engine to abrasive material in the oil. Whatever the problem, lubricant usage records should be kept and analysis of parts from failed turbochargers should be made.

Lubrication failures can be caused by several things. Undersized or plugged oil lines are common. Turbocharger bearings require a constant supply of top quality, clean oil at full engine oil pressure. A momentary interruption of oil supply can cause turbocharger overheating. Oil should pass through a good filter of proper size to insure a constant oil pressure. Even after thousands of hours of operation, bearing wear will be negligible when a sufficient supply of clean, high quality oil reaches the bearings.

Causes of Bearing Wear

Turbocharger bearings will show considerable wear when abrasives are present in the oil. Such wear is prevalent on the thrust bearing and outside diameters of the shaft bearings. Abrasive particles can sometimes be so small they escape the centrifuge effect of spinning bearings. In such cases, considerable scoring of the journal sections of the rotor shaft will be noted. Acids in lesser quality oils can corrode shafts, introducing abrasive contaminants into the system.

Cold Engine Start-Up/Hot Engine Cool Down

Cold engine startup can cause oil lag, which results in oil starvation. The results will be obvious. Low or no oil pressure can cause the bearings and shaft to overheat. Unnecessary wear then becomes apparent. Oil leakage past the compressor seal rings and turbine seal rings can be caused by a clogged filter element or restricted oil flow.[Marine diesel should be run at idle for 3 to five minutes to allow oil time to permeate the turbo bearings. Likewise, when ready to shut down your engine, run it at idle for three minutes to give the turbo time to slow down. Remember that when you should down the engine oil will stop being pumped to your turbo, but the blades may still be turning.—Ed.]

Foreign Material

Foreign material intake causes damage, and possible failure, of turbine wheel blades. Such material can be pieces of burned or broken valves, or from other internal engine parts or initial wear-in of a recently overhauled engine. Material can break out of hot manifolds and ports to cause damage. Some material can be from improperly installed gaskets or other negligence of a mechanic. Compressor wheel breakage can also occur from foreign material intake. Sometimes pieces from the air cleaner system can break loose. Particles from hose connections or pieces of rubber or wire can be ingested.

The cleaner the system, the better it will run. Some foreign material such as sand or salt cannot be avoided. Under such dirty conditions the air filter change intervals should be accelerated.

High Exhaust Temperatures

High exhaust temperatures can damage the turbocharger. Over speeding and over fueling of an engine can drastically increase exhaust temperature. Clogged air filters, restricted exhaust, high altitude engine operation and engine lugging can increase exhaust temperatures. Air inlet restrictions can result in excessive exhaust temperatures, and can literally cause a system to burn itself up.

Summary

In summary, it is better to invest in proper installation, proper preventive maintenance and to use a better premium grade oil than to live with what will otherwise be the inevitable result. Premium quality engine oils in all straight grade viscosities and SAE 15W-40 and SAE 10W-30 are recommended.